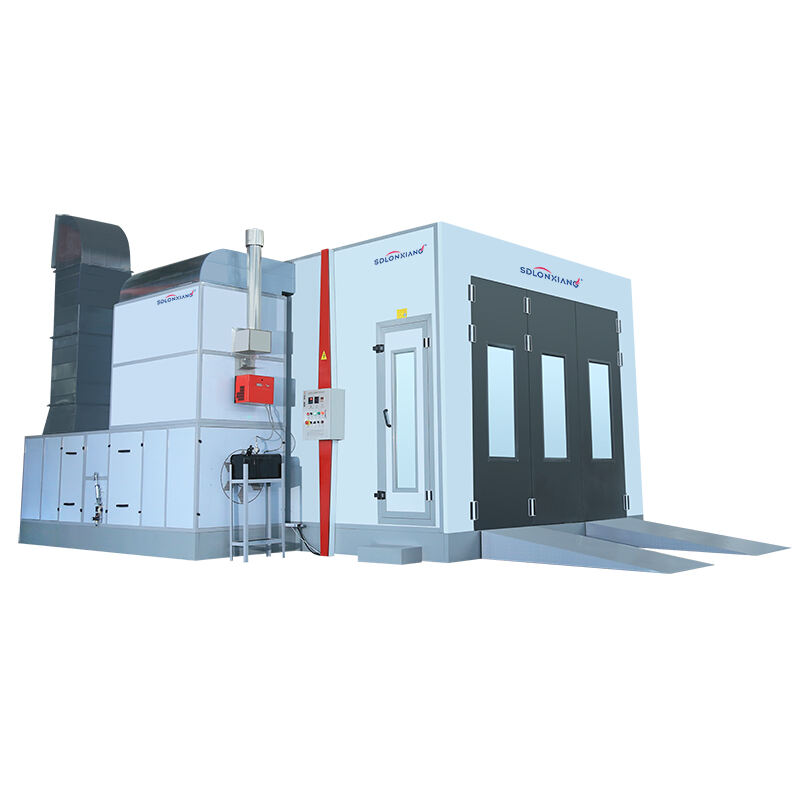

spray booth equipment

Spray booth equipment represents a critical component in modern industrial finishing operations, serving as specialized enclosed environments designed to contain and control the spray painting process. These sophisticated systems create optimal conditions for applying various coatings, paints, and finishes while maintaining strict safety and environmental standards. The primary function of spray booth equipment centers on providing controlled airflow patterns that capture overspray particles and volatile organic compounds, preventing them from escaping into the surrounding workspace. This containment capability protects both operators and the environment from potentially harmful substances. Modern spray booth equipment incorporates advanced filtration systems that remove contaminants from the air before releasing it to the atmosphere, ensuring compliance with environmental regulations. The technological features of spray booth equipment include precision-engineered ventilation systems that create laminar airflow patterns, promoting even coating distribution and superior finish quality. Temperature and humidity controls maintain optimal conditions for different coating materials, while integrated lighting systems provide excellent visibility for detailed work. Many units feature programmable control panels that allow operators to adjust parameters based on specific project requirements. Fire suppression systems and explosion-proof electrical components ensure maximum safety during operations. The applications of spray booth equipment span numerous industries, including automotive manufacturing, aerospace, furniture production, industrial machinery, and architectural metalwork. These systems accommodate various coating processes, from automotive refinishing and powder coating to specialty applications requiring precise environmental controls. The versatility of spray booth equipment makes it indispensable for businesses requiring consistent, high-quality finishes while maintaining regulatory compliance and operator safety standards.