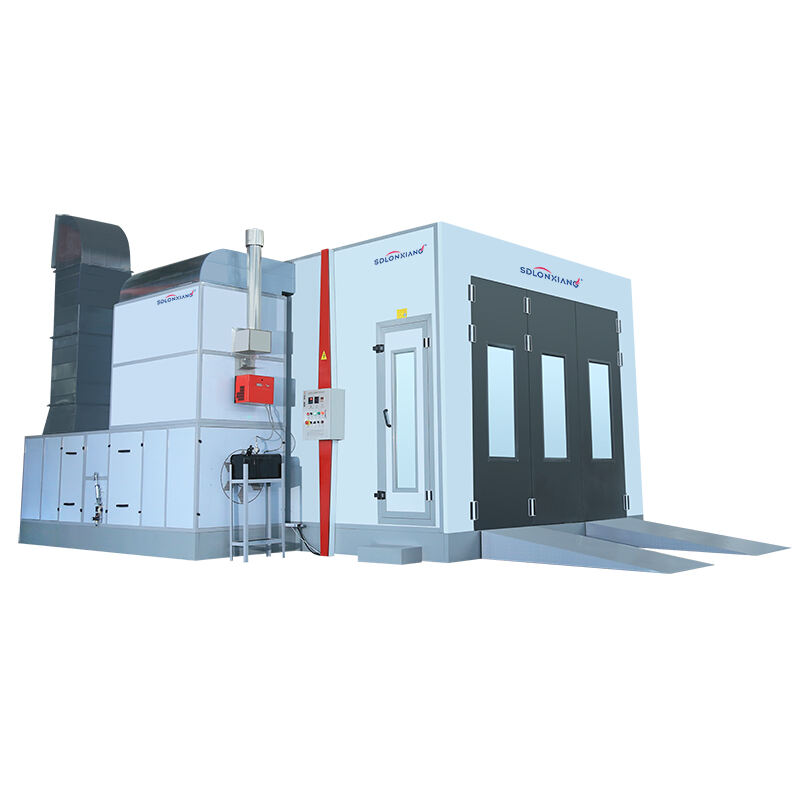

temp spray booth

A temp spray booth represents a revolutionary solution for businesses requiring flexible, cost-effective painting facilities without the permanent infrastructure investment. These portable spray booth systems deliver professional-grade paint finishing capabilities while offering unmatched mobility and setup convenience. The temp spray booth combines advanced filtration technology with durable construction materials to create controlled painting environments that meet strict safety and quality standards. Modern temp spray booth designs incorporate high-efficiency particulate air filters, powerful exhaust systems, and flame-retardant materials to ensure optimal performance across diverse applications. These units feature modular construction allowing rapid assembly and disassembly, making them ideal for temporary projects, remote locations, or businesses with changing spatial requirements. The temp spray booth typically includes integrated lighting systems, providing uniform illumination essential for precise color matching and finish quality assessment. Advanced models feature variable airflow controls, enabling operators to adjust ventilation rates based on specific coating materials and environmental conditions. The structural framework utilizes lightweight yet robust materials, ensuring stability during operation while maintaining portability for relocation. Fire suppression systems and emergency ventilation features enhance safety protocols, protecting both operators and surrounding areas from potential hazards. Many temp spray booth configurations include climate control capabilities, maintaining optimal temperature and humidity levels for superior coating adhesion and curing. The versatile design accommodates various workpiece sizes, from small automotive components to large industrial equipment. Installation requires minimal site preparation, often involving simple electrical connections and ventilation arrangements. Quality temp spray booth systems comply with environmental regulations and occupational safety standards, providing businesses with compliant painting solutions. These temporary facilities prove invaluable during building renovations, equipment maintenance, or seasonal production increases when permanent booth capacity becomes insufficient.