Efficient Airflow Systems for Optimal Paint Distribution

Balanced Pressure Zones for Overspray Containment

Maintaining balanced pressure zones is crucial for minimizing overspray in spray booth operations. By carefully managing the airflow, we ensure that paint particles are efficiently contained, enhancing the quality of the finish. Techniques such as adjusting fan speeds and optimizing duct configurations play a significant role in creating these pressure zones, effectively reducing overspray. According to industry standards, such optimized pressure systems can reduce overspray by up to 30%, leading to significant cost savings and improved environmental compliance. Ensuring balanced pressure zones not only enhances paint distribution but also contributes to safer work environments.

Customizable Airflow Patterns for Automotive Paint Booths

Customizable airflow patterns in automotive paint booths offer distinct advantages for different types of paints and finishes. Tailoring airflow to specific needs helps improve both efficiency and the quality of the end product. For instance, laminar airflow is ideal for clear coats, while downdraft patterns suit base coats best. Case studies across several facilities have shown that tailored airflow can reduce paint defects by 25%, thus enhancing finish quality. Industry experts believe that customization is essential in minimizing paint waste and achieving superior finishes, particularly in high-stakes automotive industries.

Energy-Recovery Ventilation in Industrial Spray Booth Operations

Energy-recovery ventilation (ERV) systems in industrial spray booths are transforming energy efficiency and environmental impact. These systems recover heat from exhaust air to pre-condition incoming air, significantly cutting down energy costs. An energy audit in a mid-sized facility demonstrated savings of up to 20% in energy consumption after implementing ERV. Beyond cost savings, ERV systems contribute positively to the environment by reducing the carbon footprint of spray booth operations. They offer an effective strategy for companies aiming to balance performance with sustainability, making them an attractive solution for forward-thinking industrial spray booth suppliers.

HEPA Filtration Systems in Industrial Spray Booth Design

HEPA filtration systems play a crucial role in maintaining clean air standards in industrial spray booth applications. These filters are renowned for capturing particulate matter with an efficiency rate of up to 99.97%, ensuring a safer and cleaner working environment. According to industry performance data, HEPA filters are particularly effective in spray booths, as they eliminate airborne particles that can compromise both finish quality and worker health. Regulatory bodies often mandate HEPA filtration in certain industries to adhere to strict environmental compliance requirements, further emphasizing their importance in spray booth operations.

Activated Carbon Filters for VOC Emission Control

Activated carbon filters are essential in controlling VOC emissions during spray painting processes, thereby promoting cleaner air and regulatory compliance. These filters function by adsorbing VOCs through their porous structure, effectively reducing harmful emissions. Studies have demonstrated a significant decrease in VOC levels in environments utilizing activated carbon filters. Compliance with VOC emission regulations is critical, and these filters help industries meet stringent standards, ensuring safety and environmental responsibility.

Cyclonic Pre-Filters for Large Particle Removal

Cyclonic pre-filters are highly effective in removing large particles from the airflow in spray booth systems. They function by inducing a centrifugal force that separates larger particles from the air stream, significantly reducing filter clogging and subsequent maintenance costs. Data suggests that the use of cyclonic pre-filters can extend the lifespan of downstream filters by decreasing the frequency of blockages. Best practices for integrating these filters involve adapting existing spray booth systems to maximize efficiency and ensure seamless operation.

Humidity Management for Furniture Spray Booth Applications

Humidity control is critical in furniture spray booths, impacting adhesion and quality of finishes significantly. Inconsistent humidity levels during the coating process can lead to defects like blistering, cracking, or weak adhesion, undermining the product's durability and aesthetic. Successful humidity management in furniture manufacturing is demonstrated by several case studies, showcasing how regulated humidity leads to superior finish quality. Research suggests that optimal humidity levels for coatings in furniture finishing generally range between 40-60%. Maintaining these levels ensures smoother application and enhances the overall resistance of the coating to environmental factors.

Temperature Regulation in Oven Spray Booth Curing Processes

Precise temperature regulation in oven spray booth curing processes is essential for the integrity and strength of the coating finish. Low or fluctuating temperatures can result in incomplete curing, leading to poor adhesion and reduced durability. Various coatings require specific temperature ranges; for instance, powder coatings often need curing at temperatures between 160°C and 210°C. Expert testimonials highlight advancements in temperature control technologies, such as infrared and convection ovens, which optimize energy use and improve curing efficiency within these booths. These technologies not only enhance the quality of the finish but also help in reducing energy consumption, aligning with modern sustainability goals.

Automated Environmental Monitoring Systems

Automated monitoring systems offer significant advantages for maintaining climate control in industrial spray booths. These systems utilize IoT technology to provide real-time data on environmental conditions, enabling precise adjustments to maintain ideal temperature and humidity levels. Integration with IoT allows for comprehensive data collection and analysis, optimizing operational conditions continuously. Companies integrating automated climate control systems report improved operational efficiency by minimizing manual monitoring and adjustments, reducing human error, and ensuring consistent environmental conditions, leading to enhanced productivity and quality control in the spraying process.

Explosion-Proof Lighting for Vehicle Spray Booth Safety

Explosion-proof lighting is critical in vehicle spray booths due to the presence of flammable materials. These environments require specialized lighting to prevent ignition caused by electrical components, ensuring the safety of both personnel and equipment. According to industrial safety reports, the adoption of explosion-proof lighting in hazardous areas has significantly reduced the number of incidents related to lighting-induced fires. By adhering to stringent specifications and standards set by organizations like the National Fire Protection Association (NFPA), these lights must be enclosed in protective casings to prevent sparks. Such measures underscore the vital role that explosion-proof lighting plays in maintaining a secure environment within spray booths.

Fire-Rated Insulation Materials

In spray booths, fire-rated insulation materials are essential to mitigate fire hazards. These materials safeguard the booth structure and the industrial setting from potential fire incidents. Regulatory frameworks, such as those governed by the Occupational Safety and Health Administration (OSHA), mandate the use of fire-rated insulation in industrial applications to protect both personnel and property. According to industry statistics, the integration of fire-rated insulation has reduced the risk of fires in spray booths by substantial margins. By using materials that comply with these safety standards, manufacturers can minimize fire risks and ensure a safer working environment.

Emergency Stop Systems and OSHA Compliance

Emergency stop systems are vital for ensuring safety within spray booths, acting as a crucial line of defense against unforeseen accidents. These systems are designed to halt booth operations immediately, preventing potential hazards to workers and machinery. Compliance with OSHA regulations, which specify the need for effective emergency stop mechanisms in industrial environments, is mandatory. For example, past safety incidents that were mitigated by emergency stop systems underscore their importance. These systems not only enhance safety but also align with industry standards, thereby facilitating a safer work environment in spray booths.

Touchscreen Interfaces for Process Customization

Touchscreen interfaces have revolutionized paint booth operations, offering unparalleled customization and monitoring capabilities. These modern interfaces enable operators to effortlessly adjust settings such as air pressure, temperature, and spray patterns, significantly enhancing process efficiency. Users often report substantial improvements in operational speed and quality control, attributing these benefits to the intuitive nature of touchscreen technology. Additionally, while touchscreen systems are user-friendly, they may require initial training for operators to fully leverage their capabilities. This upfront investment in training ensures that staff can utilize the interfaces to optimize booth performance effectively, thus reducing downtime and increasing productivity.

IoT-Connected Industrial Spray Booth Monitoring

IoT connectivity in industrial spray booths is a game-changer for enhanced monitoring and control. By integrating IoT technologies, businesses can track real-time data on equipment performance and environmental conditions, which leads to improved operational outcomes. For example, companies adopting IoT solutions have observed reductions in energy consumption and paint waste, thanks to precise control over spray parameters. However, despite these benefits, some challenges, such as data security and the complexity of integrating IoT into existing systems, may pose initial hurdles. Addressing these challenges with proper planning and expertise can unlock immense potential for process optimization.

Preset Programs for Repeatable Finish Quality

Preset programs play a crucial role in maintaining consistent finish quality across multiple production runs. By allowing operators to predefine settings such as spray speed and pressure, these programs minimize variability and ensure uniform product outcomes. Numerous case studies highlight how automated preset parameters lead to significant reductions in manufacturing defects and material waste. Furthermore, the use of preset programs not only enhances finish consistency but also boosts job efficiency by streamlining the setup process, ultimately saving time and resources. This approach aligns with sustainable practices by minimizing resource utilization and maximizing output quality.

Energy-Efficient Motors for Industrial Spray Booth Suppliers

Energy-efficient motors play a pivotal role in minimizing operational costs and enhancing sustainability for industrial spray booth suppliers. By integrating these motors, booths can significantly cut down on energy consumption, leading to reduced operating expenses. A report highlighted that adopting energy-efficient technologies in spray booths can result in energy savings of up to 30%, emphasizing their importance in today's eco-conscious market (KnowledgeHub Research). For instance, companies like Global Finishing Solutions have been at the forefront, promoting sustainability by incorporating efficient motors in their spray booths. These examples set a benchmark for other manufacturers aiming to enhance their operational efficiency while contributing to environmental sustainability.

Closed-Loop Water Filtration Systems

Closed-loop water filtration systems offer a sustainable solution for reducing water consumption and minimizing wastewater generation in spray booths. These systems recycle and reuse the water used during the spray painting process, thereby conserving water resources and reducing environmental impact. Evidence shows that such systems can save up to 90% of water typically used in traditional spray booths, drastically cutting down wastewater production. They incorporate advanced filtration technologies that ensure compatibility with existing booth setups, facilitating easy integration. This method not only supports sustainable practices but also results in long-term savings and compliance with stricter environmental regulations.

Recyclable Material Construction

The trend towards using recyclable materials in constructing spray booths is gaining traction, reflecting a shift toward more sustainable industrial practices. Utilizing recyclable materials decreases the environmental footprint, as these materials can be reclaimed and reused, reducing the need for raw resources. This approach contributes significantly to both environmental protection and cost savings, aligning with global sustainability goals. Data indicates that employing sustainable materials can lead to reduced manufacturing costs and simplification of regulatory compliance due to fewer emissions and waste generation. This trend is a significant step toward transforming the industry, showcasing how eco-friendly building practices can lead to tangible benefits.

Modular Designs for Multi-Sector Use

Modular designs have revolutionized the use of spray booths across multiple sectors, providing unmatched adaptability. These designs allow industries to customize spray booths to their specific needs quickly, enabling swift transitions between different operational requirements. For instance, a company can easily modify modular spray booths to accommodate different sizes and types of products, enhancing their flexibility. A prominent case study involves a furniture manufacturing company that successfully adapted a modular booth design to fit new, larger furniture models, streamlining their production process and increasing output. The economic benefits of modular spray booths are noteworthy; they reduce the need for frequent purchases or complete overhauls of equipment, resulting in significant cost savings over time. This adaptability not only boosts operational efficiency but also ensures that businesses can stay competitive across diverse industries.

Heavy-Duty Construction for Aerospace Applications

In the highly demanding aerospace sector, heavy-duty construction spray booths are essential to meet rigorous performance and safety standards. Aerospace applications require booths that can withstand extreme conditions, such as high velocities of airflow and precise temperature controls, to ensure optimal coating of large, intricate aircraft components. One example of aerospace-specific configurations includes large-scale booths with reinforced structures and advanced filtration systems to handle the delicate materials often used in aircraft. Industry standards like the SAE International specifications guide the design and construction of these booths, ensuring they meet stringent quality and safety criteria. It is crucial for aerospace spray booths to comply with these standards to maintain the integrity and performance of the components they produce, making heavy-duty construction an indispensable feature.

Scalable Configurations for Batch Production

Scalable configurations in spray booths play a pivotal role in enhancing flexibility for batch production operations. These configurations allow businesses to adjust the size and functionality of their spray booths based on changing production volumes, which is particularly beneficial in industries with fluctuating demands. Statistical data indicates that scalable setups can lead to efficiency improvements of up to 20%, as they enable companies to swiftly increase or decrease production capacity without a complete system overhaul. For example, a case study of an automotive parts supplier demonstrated significant success after implementing scalable spray booth designs, allowing the company to efficiently manage shifts from small to large batch production. This adaptability ensures that production processes are both cost-effective and responsive to market demand, reducing downtime and maximizing resource utilization.

FAQ

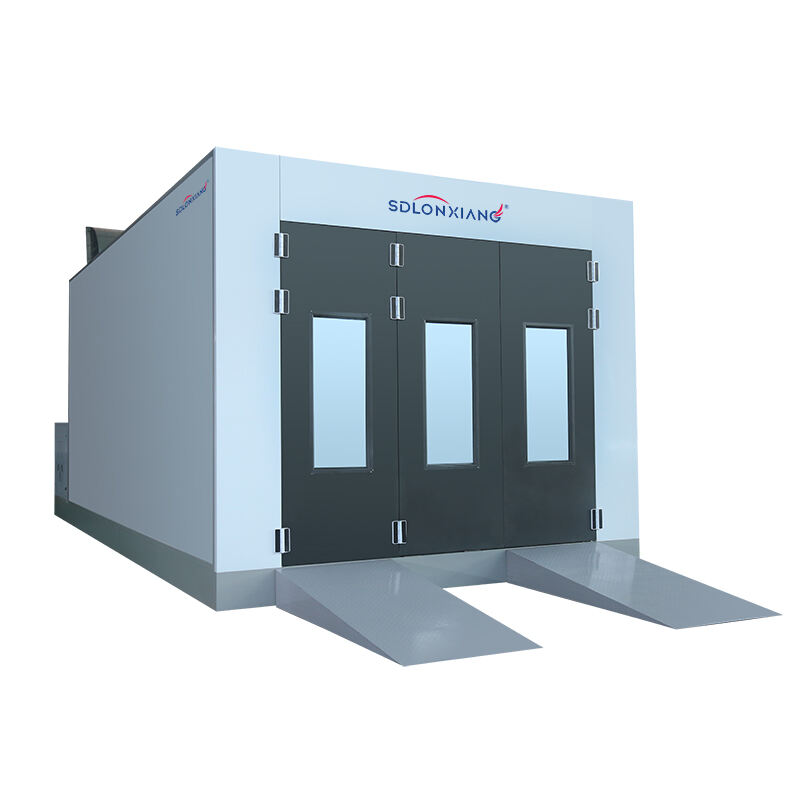

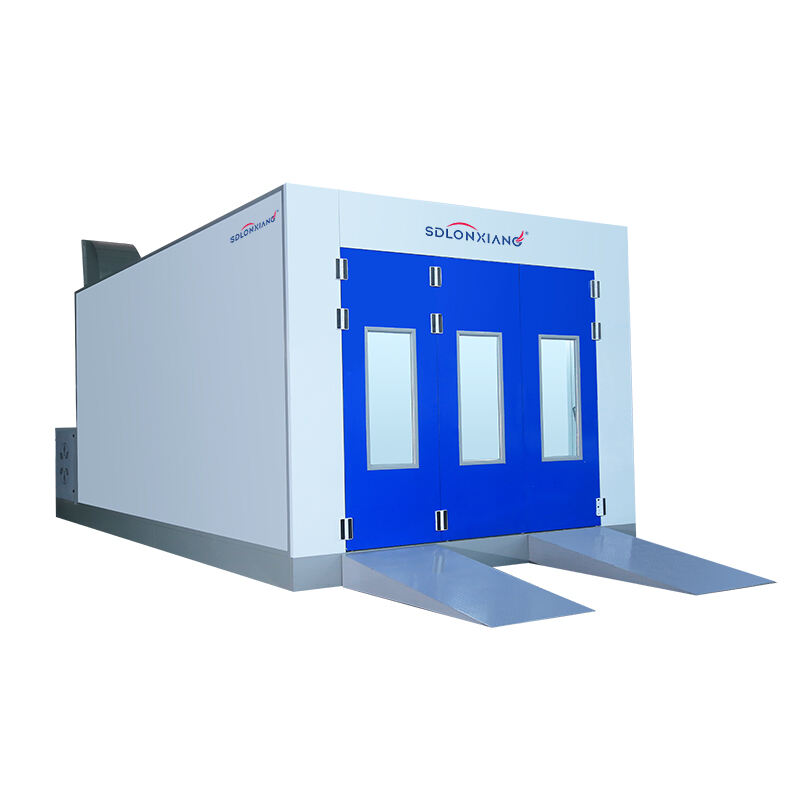

What are Industrial Spray Booths used for?

Industrial Spray Booths are used for applying coats of paint or other finishes to products through spray painting processes, providing controlled environments to enhance the quality and efficiency of the coating application.

How do energy-recovery ventilation systems benefit spray booths?

Energy-recovery ventilation systems benefit spray booths by recovering heat from exhaust air to pre-condition incoming air, which significantly reduces energy costs and improves environmental sustainability.

Why is airflow management important in industrial spray booths?

Airflow management is vital to contain paint particles efficiently and reduce overspray, ensuring a high-quality finish and minimizing environmental impact while enhancing worker safety within the booth.

What role do HEPA filters play in spray booths?

HEPA filters in spray booths capture particulate matter with high efficacy, ensuring a cleaner and safer working environment by eliminating airborne particles that compromise both finish quality and worker health.

How are scalable configurations advantageous for spray booths?

Scalable configurations allow spray booths to adapt to changing production volumes, enhancing flexibility and operational efficiency without necessitating a complete system overhaul.

Table of Contents

-

Efficient Airflow Systems for Optimal Paint Distribution

- Balanced Pressure Zones for Overspray Containment

- Customizable Airflow Patterns for Automotive Paint Booths

- Energy-Recovery Ventilation in Industrial Spray Booth Operations

- HEPA Filtration Systems in Industrial Spray Booth Design

- Activated Carbon Filters for VOC Emission Control

- Cyclonic Pre-Filters for Large Particle Removal

- Humidity Management for Furniture Spray Booth Applications

- Temperature Regulation in Oven Spray Booth Curing Processes

- Automated Environmental Monitoring Systems

- Explosion-Proof Lighting for Vehicle Spray Booth Safety

- Fire-Rated Insulation Materials

- Emergency Stop Systems and OSHA Compliance

- Touchscreen Interfaces for Process Customization

- IoT-Connected Industrial Spray Booth Monitoring

- Preset Programs for Repeatable Finish Quality

- Energy-Efficient Motors for Industrial Spray Booth Suppliers

- Closed-Loop Water Filtration Systems

- Recyclable Material Construction

- Modular Designs for Multi-Sector Use

- Heavy-Duty Construction for Aerospace Applications

- Scalable Configurations for Batch Production

- FAQ