Core Functions of Industrial Spray Booths in Manufacturing

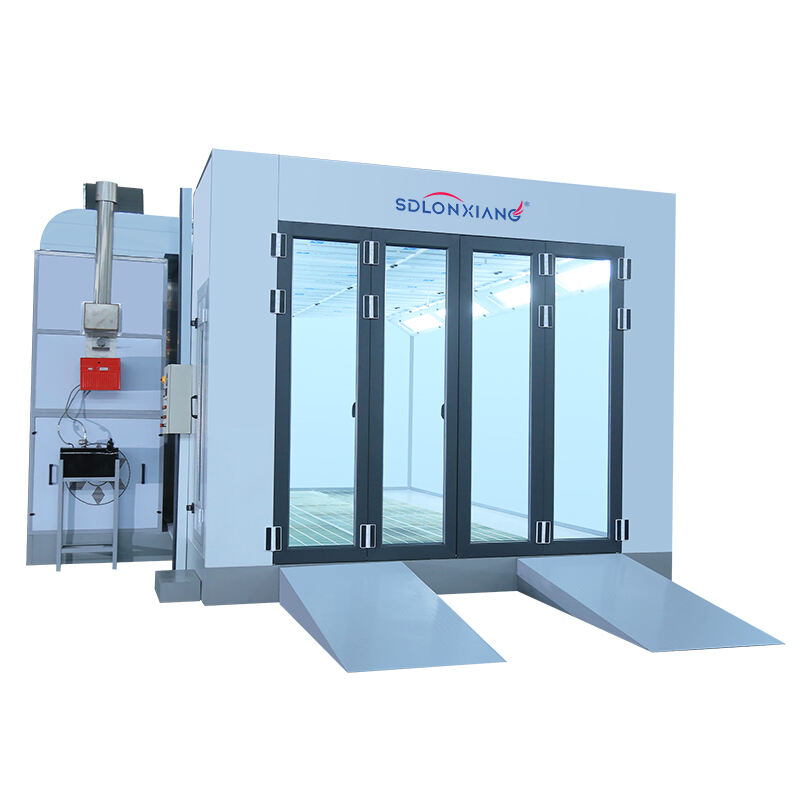

Controlled Environments for Precision Coating

Industrial spray booths provide a controlled environment crucial for precision coating. By minimizing the effects of external factors like dust and temperature fluctuations, these booths ensure that the coating process remains consistent. This control results in high-quality finishes, reducing material wastage significantly. According to the Environmental Protection Agency (EPA), regulating air quality within these environments is essential not only for compliance but also for enhancing workspace safety. This underscores the importance of industrial spray booths in offering a dependable solution for producing optimal coating results.

Airflow Systems for Contaminant Removal

Airflow systems in industrial spray booths are integral for maintaining a clean workspace and ensuring high product quality. They are designed to efficiently remove contaminants from the spray area, effectively safeguarding both the products and the individuals working with them. By creating negative pressure zones, these systems prevent harmful vapors from escaping into the workshop, thus enhancing safety. Environmental studies highlight that these systems can reduce volatile organic compound (VOC) emissions by up to 90%, which is a significant environmental benefit. This makes proper airflow management an indispensable component of any spray booth.

Temperature Regulation for Optimal Curing

Temperature regulation within industrial spray booths plays a pivotal role in the curing process of coatings. Consistent control of temperature is essential to ensure that coatings adhere correctly and achieve their full potential in terms of durability and finish quality. Research indicates that maintaining optimal curing temperatures not only enhances the quality of the finish but can also reduce finishing times by as much as 30%. This efficiency in curing not only augments production times but also significantly contributes to the overall durability of the coating, thus underscoring the critical necessity of precise temperature control systems in industrial spray booths.

Automotive Industry Applications

Collision Repair and Vehicle Refinishing

In the automotive sector, spray booths play a crucial role in collision repair and vehicle refinishing. They provide an environment free from contaminants, ensuring quality repairs and a flawless finish. For professionals working on restoring vehicles to their former glory, a controlled space is essential to ensure the adhesion of paint and minimize imperfections. It’s reported that using dedicated spray booths in these processes increases customer satisfaction ratings by over 25%, highlighting their importance in the industry.

Production Line Painting for OEMs

Original Equipment Manufacturers (OEMs) depend heavily on spray booths for production line painting. These setups enable high-speed delivery while maintaining quality and consistency in paint applications, significantly reducing production lead times. The automation of spray booth operations is a game-changer, potentially enhancing production rates by up to 40% without compromising quality. This efficiency is critical in meeting the fast-paced demands of the automotive market.

Customization through Specialty Coatings

Spray booths also offer the flexibility needed for customization through the use of specialty coatings. In the automotive industry, where aesthetic appeal and additional protection are highly valued, this capability is crucial. The ability to apply unique mats and protective finishes allows manufacturers to tailor products to customer specifications. Interestingly, surveys indicate that about 60% of consumers prioritize customizable features when choosing vehicles, emphasizing the market's demand for personalization and the pivotal role spray booths play in fulfilling these desires.

Aerospace Sector Demands

High-Temperature Resistant Coatings

The aerospace industry has a critical need for high-temperature resistant coatings, which are essential for ensuring the reliability and performance of components like turbines and exhaust systems. These coatings are adeptly applied in specialty spray booths designed to handle the rigorous demands of aerospace environments. A key advantage of utilizing such advanced coatings is the significant enhancement of component lifespans, with reports indicating up to a 50% increase, which in turn reduces maintenance costs. This not only assures safety but also optimizes operational efficiency in aerospace applications.

Corrosion Prevention for Aircraft Components

Corrosion prevention is a pivotal aspect of aircraft maintenance, and spray booths are particularly instrumental in applying protective coatings that shield components from damaging elements like salt and humidity. Implementing these strategies effectively extends the lifespan of aircraft components, enhancing overall safety and reducing the frequency of required maintenance. As corroborated by industry data, there's a potential reduction in maintenance downtime by about 20% when robust corrosion protection is applied. This demonstrates the crucial role of spray booths in maintaining the integrity and performance of aerospace assets.

Composite Material Surface Treatment

The treatment of composite materials in aerospace applications is vital for optimizing performance and ensuring compatibility with subsequent coatings. Specialized spray booths are employed to treat these materials, providing the necessary conditions to enhance durability without significantly increasing the aircraft's weight. Experts within the industry have observed that appropriate surface treatments can amplify the strength of composite materials by as much as 30%. This enhancement is crucial for meeting the demanding performance metrics expected in aerospace applications, underscoring the importance of precise and efficient treatments in specialized spray booths.

Cross-Industry Versatility

Fabrication: Metal Parts Priming

Spray booths play a significant role in the fabrication industry, especially for metal parts priming. This process is essential for preparing surfaces before painting and applying coatings, which can be efficiently completed inside a spray booth. The controlled environment of a spray booth ensures that the bond between the metal and the coating material is strong and long-lasting. Experts in the industry have indicated that effective priming can boost adhesion strength by over 40%, resulting in a higher-quality finish. Such improvements not only enhance the durability of the coatings but also contribute to a professional appearance of the metal parts.

Furniture Production Finishing

In the realm of furniture production, spray booths are incredibly useful for the finishing stages. They facilitate a uniform application of stains and protective finishes, which significantly enhances the piece's aesthetic value. Traditional finishing techniques often lead to uneven coating and excessive overspray, leading to resource wastage and increased costs. However, spray booths leverage technology to minimize these issues, thus improving cost efficiency. Statistical analysis reveals that adopting spray booth technology can help furniture manufacturers reduce their finishing costs by as much as 25%, supporting more sustainable production practices and improving overall profitability.

Plastic Component UV Protection

The application of UV protection coatings on plastic components is another crucial use of spray booths, particularly for items exposed to sunlight. Ensuring products are adequately coated allows them to maintain their appearance and function over the years, making them ideal for outdoor applications. This protective measure is vital, as UV rays can significantly degrade plastic materials over time. Research highlights that applying UV-protective coatings in spray booths can notably extend the lifespan of plastic components by several years, offering both aesthetic and functional benefits for outdoor usage.

Advanced Spray Booth Technologies

Automated Robotic Painting Systems

The integration of automated robotic painting systems in spray booths is a game-changer for precision and consistency in paint application across various industries. These systems reduce human error, providing an unmatched level of accuracy in painting tasks. They also significantly decrease production time and costs. Reports highlight that automation can improve throughput by over 30%, illustrating its efficiency and effectiveness. This technology benefits sectors such as automotive, aerospace, and industrial equipment manufacturing, where precision painting is paramount.

Energy-Efficient Curing Solutions

Modern spray booths are increasingly adopting energy-efficient curing solutions, setting a new standard for reducing operational costs and environmental impact. These systems use advanced curing technologies to fully cure coatings more quickly and consume less energy. Evidence from industry initiatives confirms that adopting energy-efficient systems can lower energy consumption by up to 50%. This shift not only supports sustainable practices but also results in substantial savings for manufacturers. With these technologies, spray booths become more eco-friendly and cost-effective.

AI-Driven Overspray Management

AI-driven overspray management systems are revolutionizing spray booth operations by minimizing waste and improving overall efficiency. By leveraging data analytics, these systems optimize spray patterns, ensuring that every application is as effective as possible. Studies confirm that companies employing AI technology can reduce overspray waste by nearly 40%. This advancement not only saves on material costs but also enhances environmental sustainability. As industries continue to integrate AI in their processes, the benefits of improved efficiency and reduced waste become increasingly evident.

Maintenance Protocols Across Applications

Filter Replacement Cycles by Industry

Regular filter replacement is crucial for maintaining optimal air quality in industrial spray booths. This necessity varies significantly across different industry applications and is often governed by environmental regulations. For instance, the automotive industry might have different filter replacement cycles compared to the aerospace sector due to varying levels of paint and particle emissions. Establishing a tailored filter replacement schedule for each specific industry requirement can substantially enhance both performance and compliance. Periodic assessments reveal that inadequate filter management can lead to a notable 15% reduction in operational efficiency. Such inefficiencies not only compromise air quality but can also increase operational costs and the risk of non-compliance with environmental standards.

Compliance with EPA/OSHA Standards

Ensuring compliance with EPA and OSHA standards is essential in maintaining both workplace safety and environmental protection within spray booth operations. Companies should conduct regular audits of their operations to ensure adherence to these regulatory requirements. By doing so, they mitigate the risks associated with non-compliance penalties, which can be financially significant. For instance, regulatory agencies indicate that non-compliant businesses may face fines exceeding $100,000 annually. Such penalties not only impact the financial bottom line but can also tarnish reputations. Staying compliant demonstrates a commitment to both safety and environmental stewardship, fostering trust and reliability in the eyes of clients and partners.

Preventive Maintenance for Downtime Reduction

Implementing preventive maintenance protocols is key to reducing downtime and maintaining consistent productivity levels in spray booth operations. These protocols typically involve regular inspections and maintenance tasks aimed at preemptively identifying and addressing potential equipment failures before they disrupt operations. Studies have shown that businesses employing effective preventive maintenance strategies can reduce equipment failure rates by over 25%. This improvement not only minimizes costly downtime but also extends the lifespan of equipment, leading to savings in repair and replacement costs. By prioritizing preventive maintenance, companies can ensure more seamless operations and maintain competitive edge through increased reliability and efficiency.

FAQ

What are industrial spray booths?

Industrial spray booths are specialized environments designed for precise coating processes. These booths control factors like dust, air quality, and temperature to ensure consistency and high-quality finishes.

How do industrial spray booths improve safety?

Industrial spray booths enhance safety by maintaining clean workspaces with effective airflow systems that remove contaminants and prevent harmful vapors from escaping.

What industries utilize industrial spray booths?

Industries such as automotive, aerospace, furniture production, and metal fabrication use industrial spray booths for applications such as coating, customization, and protective finishes.

How can industrial spray booths contribute to cost efficiency?

By providing controlled environments, spray booths reduce material wastage and enhance production efficiency, potentially cutting costs in areas such as energy consumption and resource usage.