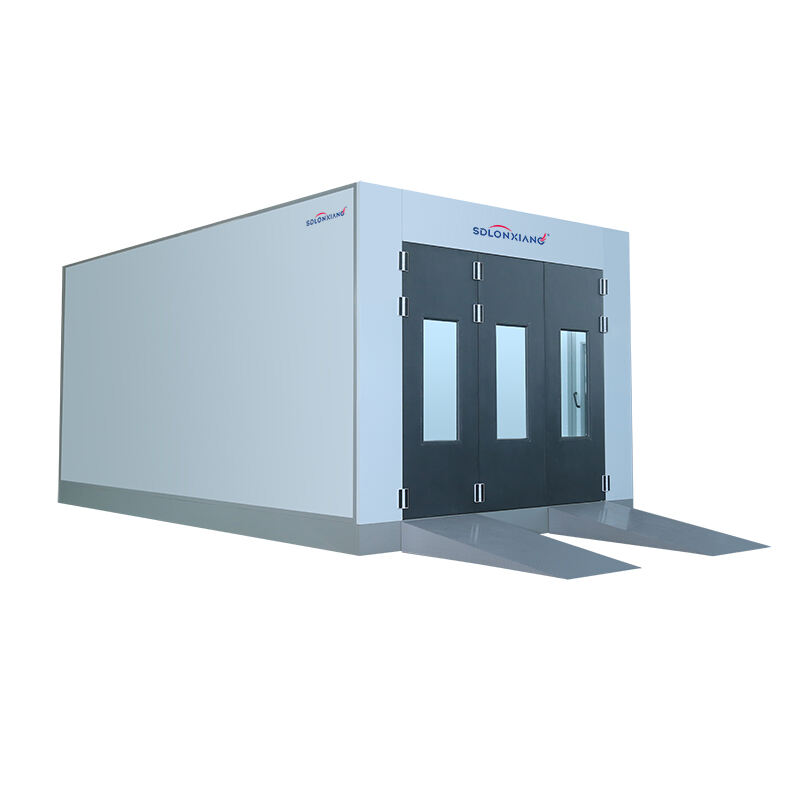

paint booth oven

A paint booth oven represents a sophisticated industrial heating system specifically designed to accelerate the curing and drying processes of painted surfaces in controlled environments. This specialized equipment combines the functionality of a traditional spray booth with advanced thermal management capabilities, creating an integrated solution for professional finishing operations. The paint booth oven operates by maintaining precise temperature controls while providing optimal airflow patterns that ensure uniform heat distribution across all painted surfaces. Modern paint booth oven systems incorporate state-of-the-art heating elements, including gas-fired burners, electric heating coils, or infrared technology, depending on specific application requirements and energy efficiency preferences. The technological framework of a paint booth oven includes advanced filtration systems that capture overspray particles and volatile organic compounds, ensuring environmental compliance and worker safety. These systems feature programmable control panels that allow operators to customize temperature profiles, timing sequences, and ventilation patterns according to specific coating requirements. The paint booth oven typically includes multiple zones with independent temperature controls, enabling manufacturers to process different types of coatings simultaneously or accommodate varying cure schedules. Safety features are paramount in paint booth oven design, incorporating explosion-proof electrical components, emergency shutdown systems, and comprehensive fire suppression mechanisms. Applications span across automotive refinishing, industrial equipment manufacturing, furniture production, aerospace components, and architectural metalwork. The versatility of a paint booth oven makes it suitable for processing everything from small decorative items to large industrial machinery components. Energy recovery systems integrated into modern paint booth oven designs capture waste heat and redirect it back into the process, significantly reducing operational costs while maintaining environmental sustainability standards.