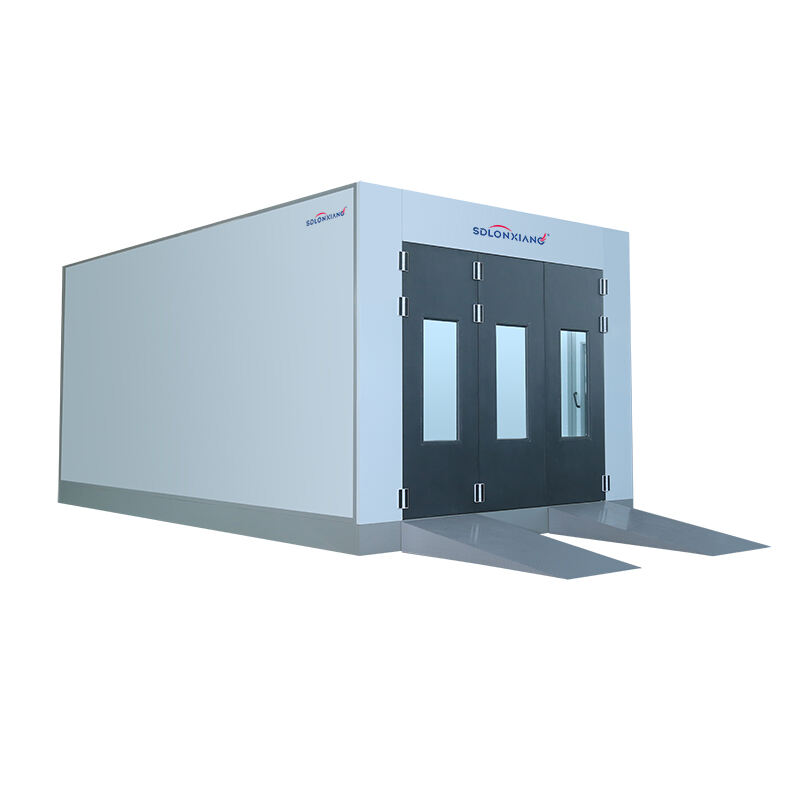

car painting booth

A car painting booth represents a specialized enclosed workspace designed specifically for automotive refinishing operations. This sophisticated equipment creates a controlled environment where vehicles receive professional paint applications with optimal results. The car painting booth functions as a critical component in automotive repair facilities, manufacturing plants, and custom shops worldwide. Modern car painting booth systems incorporate advanced filtration technology that removes airborne particles and contaminants from the workspace atmosphere. These units maintain precise temperature control throughout the painting process, ensuring consistent paint curing and adhesion properties. The car painting booth features powerful ventilation systems that create positive air pressure, preventing dust and debris from entering the work area during critical coating applications. Cross-draft, semi-downdraft, and full downdraft airflow patterns are available depending on specific operational requirements. Professional car painting booth installations include integrated lighting systems with high-intensity fixtures that provide uniform illumination across all vehicle surfaces. This lighting configuration enables technicians to identify surface imperfections and ensure complete coverage during paint application procedures. The car painting booth structure typically consists of insulated panels that maintain thermal stability and reduce energy consumption. Fire suppression systems are integrated into car painting booth designs to meet safety regulations and protect valuable equipment investments. Heating elements within the car painting booth accelerate paint curing processes, reducing cycle times and increasing productivity levels. Advanced control panels allow operators to monitor and adjust environmental parameters including temperature, humidity, and airflow velocity. Many car painting booth models feature automated programming capabilities that optimize settings for different paint types and application methods. The car painting booth serves multiple applications beyond standard refinishing work, including primer application, clear coat finishing, and specialized coating procedures for commercial vehicles, motorcycles, and industrial equipment components.