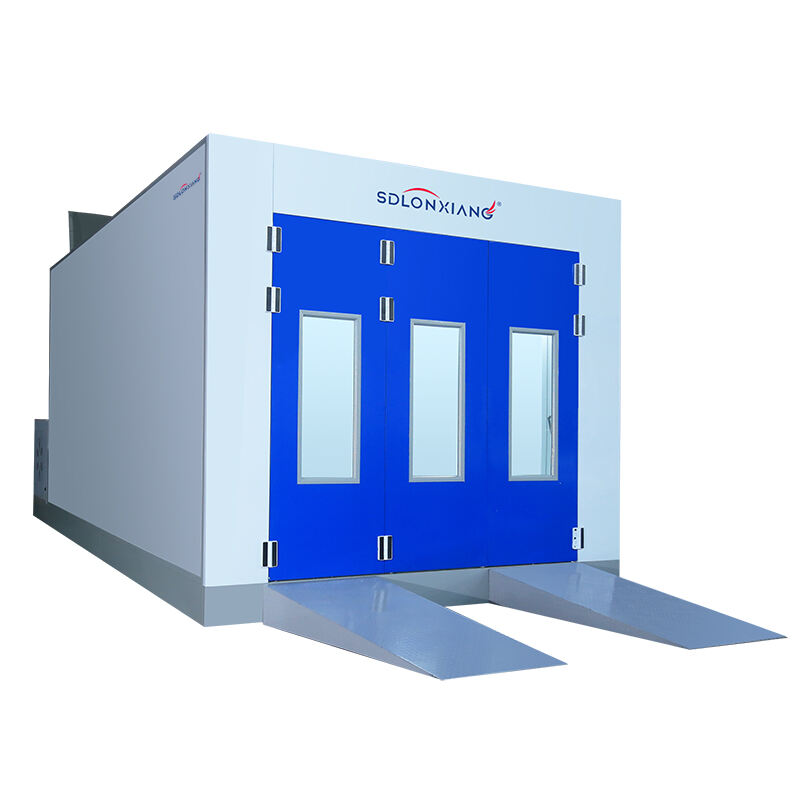

spray booth for painting cars

A spray booth for painting cars represents a specialized enclosed environment designed to deliver professional automotive painting results while ensuring safety, efficiency, and environmental compliance. This controlled workspace creates optimal conditions for applying paint, primer, and protective coatings to vehicles, transforming the painting process from a challenging outdoor task into a precise, manageable operation. The spray booth for painting cars incorporates advanced ventilation systems that maintain consistent airflow patterns, effectively capturing overspray and preventing contamination from dust, debris, and atmospheric pollutants that could compromise the finish quality. These sophisticated enclosures feature filtered air intake systems that remove particles as small as 0.3 microns, ensuring the paint environment remains pristine throughout the application process. Temperature and humidity controls within the spray booth for painting cars maintain ideal atmospheric conditions, typically between 65-75 degrees Fahrenheit with relative humidity levels below 50 percent, preventing paint defects such as blushing, orange peel, or poor adhesion. The lighting system utilizes high-intensity, color-corrected fixtures that eliminate shadows and provide accurate color representation, enabling painters to achieve consistent results across different vehicle sections. Modern spray booth for painting cars designs incorporate energy-efficient heating systems that accelerate curing times while reducing operational costs. The booth structure typically consists of galvanized steel panels with baked enamel finish, providing durability and chemical resistance against paint solvents and cleaning agents. Explosion-proof electrical components ensure safe operation when working with flammable materials, while emergency shut-off systems provide additional protection. These facilities accommodate various vehicle sizes, from compact cars to large commercial vehicles, with adjustable work platforms and moveable equipment to optimize workspace utilization. The spray booth for painting cars serves automotive repair shops, custom paint facilities, restoration specialists, and manufacturing operations requiring consistent, high-quality finishes.