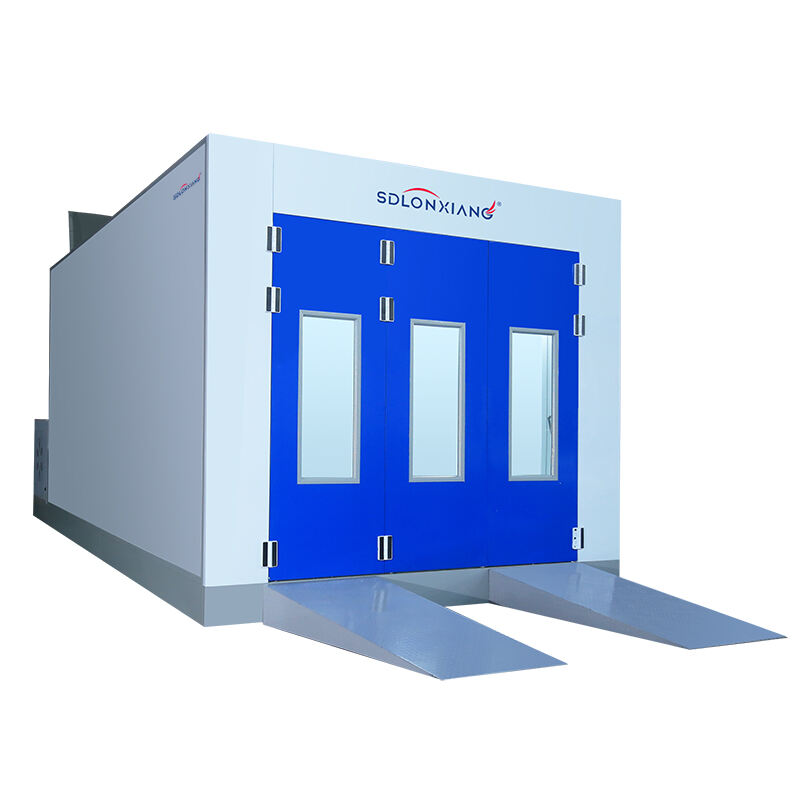

spray booth manufacturers

Spray booth manufacturers represent the backbone of modern industrial finishing operations, providing essential equipment that ensures safe, efficient, and high-quality coating applications across numerous industries. These specialized companies design, engineer, and produce sophisticated containment systems that control airborne particles, chemical vapors, and overspray during painting, powder coating, and other surface treatment processes. The primary function of spray booth manufacturers involves creating enclosed environments where operators can apply coatings while maintaining optimal air quality, temperature control, and safety standards. Their products range from small automotive touch-up booths to massive industrial installations capable of accommodating aircraft, heavy machinery, and large-scale manufacturing components. Modern spray booth manufacturers integrate advanced technologies including variable speed exhaust fans, sophisticated filtration systems, and computerized environmental controls that monitor temperature, humidity, and air circulation patterns. These technological features ensure consistent coating quality while protecting workers from hazardous fumes and maintaining compliance with environmental regulations. The applications for products from spray booth manufacturers span automotive refinishing, aerospace manufacturing, furniture production, marine vessel coating, agricultural equipment finishing, and countless other industrial sectors requiring precise surface treatments. Leading spray booth manufacturers also provide comprehensive services including installation, training, maintenance, and regulatory compliance support, ensuring their clients achieve maximum productivity and safety standards throughout the equipment lifecycle.