Selecting the right furniture spray booth for your woodworking operations requires careful consideration of multiple factors including production volume, budget constraints, and quality requirements. Whether you're running a large-scale furniture manufacturing facility or a small custom workshop, understanding the differences between industrial and DIY spray booth solutions will help you make an informed decision that maximizes both efficiency and return on investment.

The furniture finishing industry has evolved significantly over the past decade, with spray booth technology advancing to meet increasingly stringent environmental regulations and quality standards. Modern furniture manufacturers face growing pressure to reduce volatile organic compound emissions while maintaining consistent finish quality across diverse product lines. This technological evolution has created a clear distinction between professional-grade industrial systems and more affordable DIY alternatives, each serving specific market segments with unique operational requirements.

Understanding Industrial Furniture Spray Booths

Advanced Filtration and Airflow Systems

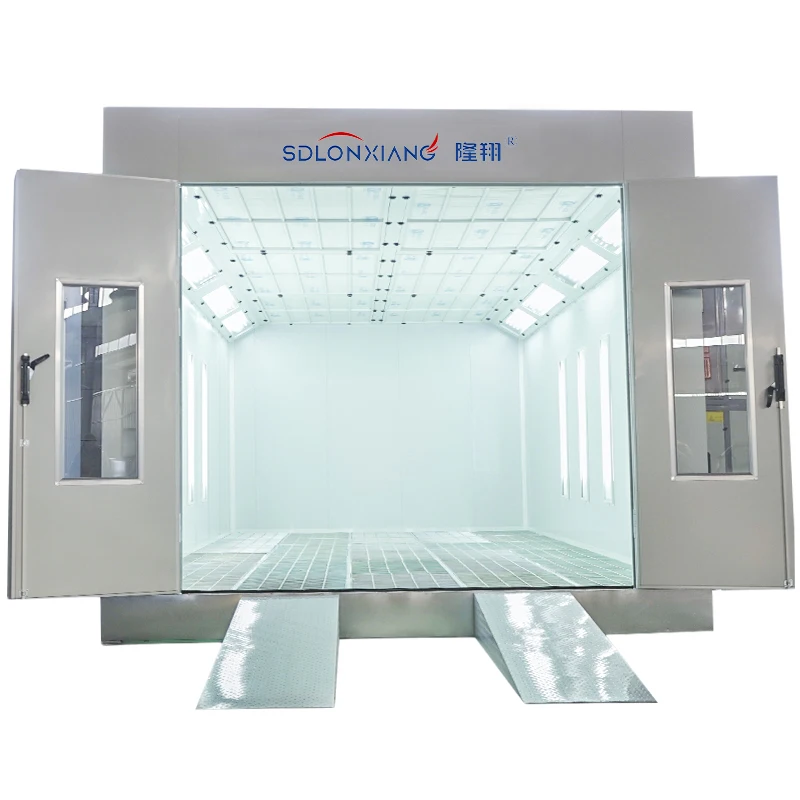

Industrial furniture spray booths incorporate sophisticated multi-stage filtration systems designed to capture overspray particles and maintain optimal air quality throughout the finishing process. These systems typically feature pre-filters, primary filters, and HEPA-grade final filters that work in conjunction to remove up to 99.97% of airborne contaminants. The controlled airflow patterns ensure consistent air velocity across the entire work area, preventing turbulence that could affect finish quality or create safety hazards.

Professional-grade ventilation systems in industrial booths maintain precise air exchange rates, typically ranging from 50 to 100 feet per minute of face velocity depending on the specific application requirements. This controlled environment eliminates the risk of contamination from external dust and debris while providing operators with a safe working atmosphere free from harmful fumes and vapors.

Compliance and Safety Features

Industrial furniture spray booths are engineered to meet or exceed strict regulatory standards including NFPA, OSHA, and EPA requirements. These systems incorporate explosion-proof electrical components, emergency shut-off systems, and fire suppression capabilities that provide comprehensive protection for both personnel and equipment. The robust construction materials and engineering standards ensure reliable operation even under demanding production schedules.

Temperature and humidity control systems maintain optimal environmental conditions for consistent finish application and curing. Advanced monitoring systems continuously track critical parameters and alert operators to any deviations that could affect product quality or safety compliance. These integrated safety features significantly reduce liability risks and insurance costs for manufacturing operations.

Production Capacity and Throughput

Large-scale industrial booths accommodate high-volume production requirements with spacious work areas that can handle multiple furniture pieces simultaneously. Automated conveyor systems and programmable controls enable consistent processing cycles that maximize throughput while minimizing labor costs. The robust construction and commercial-grade components ensure reliable operation during extended production runs without performance degradation.

Energy-efficient heating and curing systems reduce operational costs while maintaining precise temperature control for optimal finish results. Variable speed drive systems automatically adjust airflow and heating based on production requirements, optimizing energy consumption and reducing environmental impact throughout the manufacturing process.

DIY Furniture Spray Booth Solutions

Cost-Effective Entry-Level Options

DIY furniture spray booth solutions provide smaller workshops and hobbyists with affordable access to controlled finishing environments without the substantial capital investment required for industrial systems. These systems typically utilize simplified filtration methods and basic ventilation components that still provide significant improvements over open-air finishing applications. The modular design approach allows users to customize booth configurations based on available space and specific project requirements.

Portable and semi-permanent DIY booths offer flexibility for workshops with limited dedicated space or seasonal production schedules. The simplified assembly process and standard hardware requirements enable quick setup and reconfiguration as operational needs change. Basic safety features and fire-resistant materials provide essential protection while maintaining affordability for budget-conscious operations.

Customization and Scalability

DIY booth systems excel in their adaptability to unique workspace constraints and specialized finishing applications. Users can modify dimensions, airflow patterns, and filtration components to accommodate specific furniture styles or finishing techniques. This flexibility allows creative professionals to experiment with different booth configurations and optimize their setup based on practical experience and evolving requirements.

Modular expansion capabilities enable gradual system upgrades as businesses grow and production volumes increase. Component-level upgrades allow users to enhance performance incrementally without replacing the entire system, providing a cost-effective path toward more sophisticated finishing capabilities over time.

Maintenance and Operational Simplicity

Simplified mechanical systems in DIY booths reduce maintenance complexity and allow users to perform routine service tasks without specialized training or expensive service contracts. Standard replacement parts and widely available components minimize downtime and repair costs. The straightforward design philosophy prioritizes user accessibility and reduces dependency on professional technicians for routine maintenance activities.

Basic control systems and manual operation modes provide reliable functionality without complex programming or calibration requirements. This operational simplicity reduces training time for new operators and minimizes the potential for system malfunctions or user errors that could affect production schedules or finish quality.

Performance Comparison and Analysis

Finish Quality and Consistency

Industrial furniture spray booth systems deliver superior finish consistency through precise environmental controls and advanced airflow management. The controlled atmosphere eliminates variables that can affect coating application, resulting in uniform finish quality across production runs. Professional-grade filtration prevents contamination that could create surface defects or require costly rework operations.

DIY systems, while adequate for many applications, may exhibit greater variability in finish quality due to simplified environmental controls and basic filtration systems. However, skilled operators can achieve excellent results with proper technique and attention to environmental factors. The trade-off between cost and consistency becomes a critical decision factor for different operational requirements.

Operating Cost Considerations

Industrial systems typically demonstrate lower per-unit operating costs in high-volume production environments due to energy efficiency optimizations and automated process controls. The initial capital investment is offset by reduced labor costs, improved material utilization, and minimal rework requirements. Advanced monitoring systems identify optimization opportunities and prevent costly operational inefficiencies.

DIY systems excel in low-volume applications where the reduced operating complexity and minimal infrastructure requirements provide significant cost advantages. The simplified maintenance requirements and standard component availability result in predictable operating expenses that are easier to budget and manage for smaller operations.

Selection Criteria and Decision Framework

Production Volume Assessment

Production volume represents the most critical factor in determining appropriate booth technology. Operations processing more than 50 furniture pieces per week typically benefit from industrial systems due to improved efficiency and consistency requirements. The break-even analysis should consider both direct costs and productivity improvements that justify higher initial investments.

Smaller operations with irregular production schedules or specialized custom work may find DIY solutions more cost-effective and operationally appropriate. The flexibility to adjust booth configuration for different project types provides operational advantages that may outweigh the performance limitations compared to industrial systems.

Quality Requirements and Market Position

High-end furniture manufacturers targeting premium market segments require consistent finish quality that industrial booth systems provide more reliably. Customer quality expectations and warranty obligations may necessitate the superior environmental controls and contamination prevention capabilities of professional-grade equipment.

Custom furniture makers and restoration specialists often prioritize flexibility over absolute consistency, making DIY systems attractive for their adaptability to unique finishing challenges. The ability to modify booth configuration for specialized techniques or unusual piece dimensions provides operational advantages in these market segments.

Implementation and Integration Considerations

Facility Requirements and Infrastructure

Industrial furniture spray booth installations require comprehensive facility planning including adequate electrical capacity, ventilation infrastructure, and fire safety systems. The substantial space requirements and utility demands necessitate careful integration with existing production workflows and building systems. Professional installation and commissioning ensure optimal performance and regulatory compliance from the outset.

DIY systems typically require minimal facility modifications and can often utilize existing ventilation or electrical infrastructure with minor upgrades. The reduced installation complexity and lower utility requirements make DIY solutions attractive for retrofitting existing workshops or temporary facilities with limited infrastructure capacity.

Training and Operational Integration

Advanced industrial systems require comprehensive operator training to maximize system capabilities and ensure safe operation. The sophisticated control systems and monitoring capabilities demand higher skill levels but provide greater process optimization opportunities. Ongoing training programs help operators utilize advanced features and maintain optimal system performance over time.

DIY systems prioritize operational simplicity and intuitive controls that minimize training requirements. The straightforward operation modes and manual controls allow operators to become proficient quickly without extensive technical education. This accessibility advantage makes DIY systems particularly attractive for smaller operations with limited training resources.

FAQ

What factors determine whether an industrial or DIY furniture spray booth is more appropriate for my operation

The decision between industrial and DIY furniture spray booth systems depends primarily on production volume, quality requirements, budget constraints, and available facility infrastructure. Operations processing high volumes of furniture pieces typically benefit from industrial systems due to improved efficiency and consistency, while smaller workshops with irregular production schedules may find DIY solutions more cost-effective and operationally flexible.

How do operating costs compare between industrial and DIY furniture spray booth systems over time

Industrial systems generally demonstrate lower per-unit operating costs in high-volume applications due to energy efficiency optimizations and automated controls, though they require higher initial capital investment. DIY systems excel in low-volume scenarios with reduced infrastructure requirements and simplified maintenance needs, resulting in more predictable operating expenses for smaller operations.

Can DIY furniture spray booth systems meet regulatory compliance requirements for commercial operations

Basic DIY systems may meet fundamental safety requirements for small-scale operations, but commercial furniture manufacturing typically requires the comprehensive compliance features found in industrial systems. Regulatory requirements vary by location and operation scale, so consultation with local authorities and safety professionals is essential to determine appropriate system specifications for specific applications.

What are the key performance differences between industrial and DIY furniture spray booth filtration systems

Industrial furniture spray booth systems incorporate multi-stage filtration with HEPA-grade final filters achieving up to 99.97% particle removal efficiency, while DIY systems typically utilize simplified filtration methods that provide adequate protection for smaller operations but may not achieve the same contamination prevention levels required for high-end furniture finishing applications.

Table of Contents

- Understanding Industrial Furniture Spray Booths

- DIY Furniture Spray Booth Solutions

- Performance Comparison and Analysis

- Selection Criteria and Decision Framework

- Implementation and Integration Considerations

-

FAQ

- What factors determine whether an industrial or DIY furniture spray booth is more appropriate for my operation

- How do operating costs compare between industrial and DIY furniture spray booth systems over time

- Can DIY furniture spray booth systems meet regulatory compliance requirements for commercial operations

- What are the key performance differences between industrial and DIY furniture spray booth filtration systems