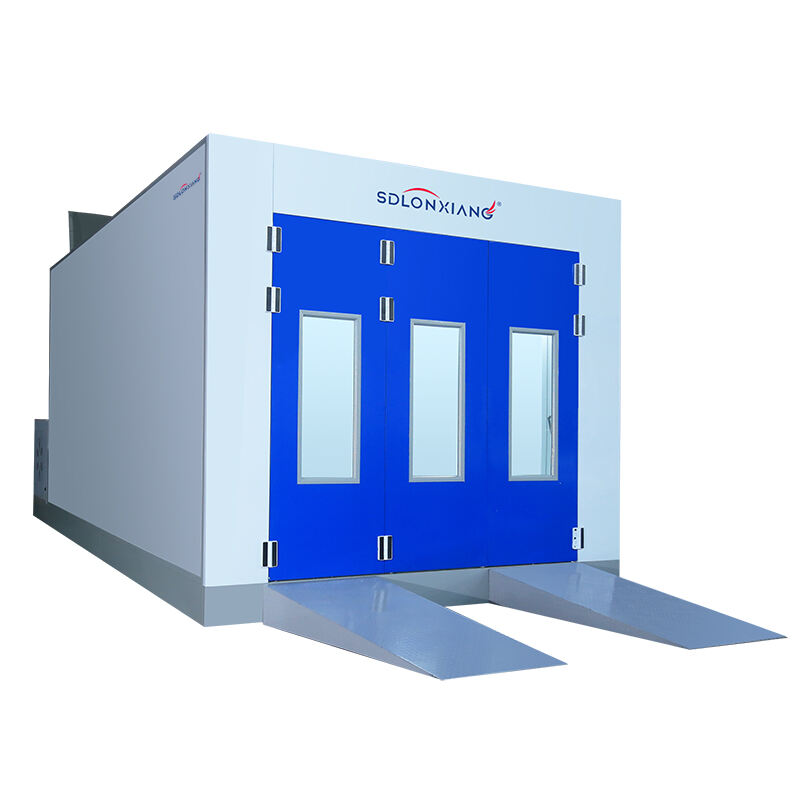

tillverkare av målningsspridningsbås

En tillverkare av målardammskåp representerar ett specialiserat industriellt företag som utformar, konstruerar och producerar slutna ventilationssystem särskilt framtagna för spritmålning och beläggningsapplikationer. Dessa tillverkare fokuserar på att utveckla omfattande lösningar som säkerställer säkra, effektiva och högkvalitativa ytbehandlingsprocesser inom olika industrier. Den främsta funktionen hos målardammskåpssystem är att innesluta overspray, kontrollera luftburna partiklar och bibehålla optimala miljöförhållanden under beläggningsoperationer. Moderna tillverkaranläggningar för målardammskåp integrerar avancerade filtreringsteknologier, exakta luftflödessystem och sofistikerade kontrollmekanismer för att leverera överlägsna prestandastandarder. De tekniska funktionerna som integreras av ledande tillverkare av målardammskåp inkluderar flerstegsfiltreringssystem, avgasfläktar med varvtalsstyrning, temperaturregleringsenheter och automatiserade övervakningssystem som spårar luftkvalitet och skåpens prestandamätningar. Dessa system fångar effektivt upp målningspartiklar, kemiska ångor och andra föroreningar samtidigt som de ger målare en ren och välbelyst arbetsmiljö. Applikationer för målardammskåpssystem omfattar bilåterförsäljningsverkstäder, industriella tillverkningsanläggningar, flyg- och rymdindustrier, möbelproduktionslinjer och anpassade tillverkningsverkstäder. Varje tillverkare av målardammskåp erbjuder vanligtvis anpassade lösningar skräddarsydda för specifika branschkrav, lokalstorlek och produktionsvolymer. Konstruktionsprocessen innebär noggrann hänsynstagande till lokala byggregler, miljöregler och säkerhetsstandarder för att säkerställa efterlevnad och optimal funktionalitet. Avancerade tillverkningsoperationer för målardammskåp använder datorstödd designprogramvara för att skapa exakta skåpkonfigurationer som maximerar effektiviteten samtidigt som energiförbrukningen minimeras. Många tillverkare erbjuder också omfattande installations tjänster, pågående underhållsstöd och operatörsutbildningsprogram för att säkerställa att kunder uppnår maximal avkastning på sin investering. Utvecklingen av målardammskåpsteknik fortskrider ständigt genom innovationer inom energieffektiva motorer, smarta kontrollsystem och miljömässigt hållbara filtreringsmaterial som minskar driftskostnaderna samtidigt som exceptionella prestandastandarder bibehålls.