Avancerad Miljökontrollteknik

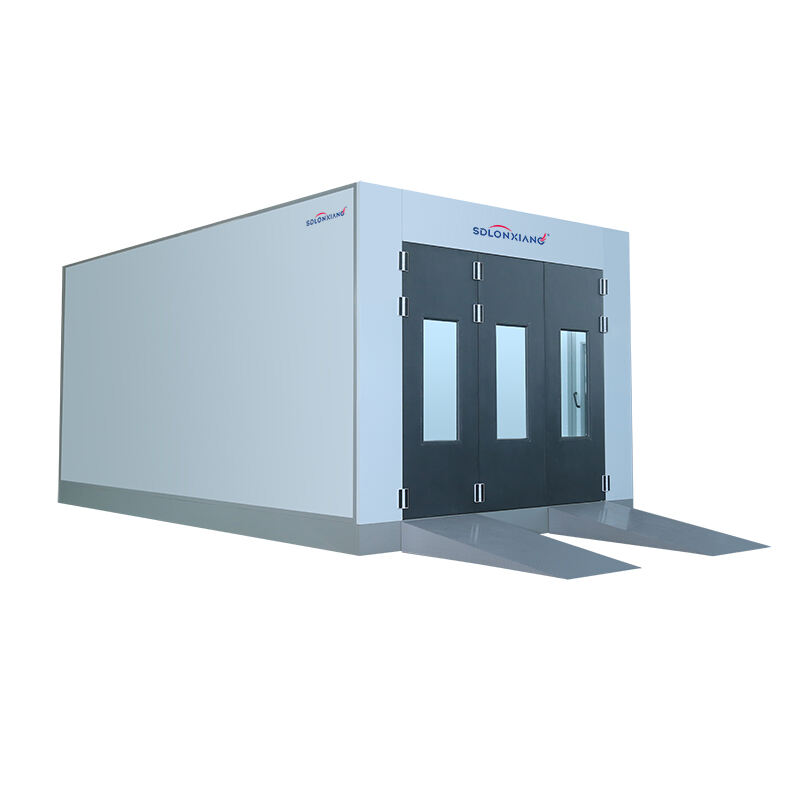

Den sofistikerade miljökontrollteknik som utvecklats av en ledande tillverkare av lackskåp för bilmålning representerar en revolutionerande metod inom bilåterfärgning, vilket omvandlar vanliga reparationssalonger till precisionsmålningsanläggningar. Detta avancerade system skapar en noggrant kontrollerad atmosfär där temperatur, fuktighet och luftkvalitetsparametrar hålls konstanta under hela målningsprocessen, vilket säkerställer optimala förhållanden för att uppnå fullt visningsrumskvalitet vid varje tillfälle. Tillverkaren av lackskåp för bilmålning har integrerat flerzons klimatstyrning som automatiskt justerar miljöförhållandena beroende på de specifika kraven från olika beläggningstyper och appliceringsmetoder. Tekniken är försedd med intelligenta sensorer som kontinuerligt övervakar luftkvaliteten, upptäcker och eliminerar luftburna föroreningar innan de kan påverka fästegenskaper eller ytans jämnhet. Filtersystemet, designat av denna tillverkare av lackskåp för bilmålning, använder en progressiv trestegsprocess som tar bort partiklar så små som 0,3 mikrometer, vilket skapar en ultraren miljö som kan mäta sig med fabriksliknande målningsanläggningar. Det automatiserade kontrollgränssnittet gör det möjligt för operatörer att välja förprogrammerade inställningar för olika färgtyper, inklusive grundfärg, klartäckare och specialytor, där systemet automatiskt justerar ventilation, temperatur och fuktighetsnivåer därefter. Denna tillverkare av lackskåp för bilmålning har integrerat energiåtervinningsystem som fångar in och återanvänder uppvärmd luft, vilket minskar driftskostnader samtidigt som optimala målningsförhållanden bibehålls under längre arbetspass. Nätverket för precisionsluftdistribution säkerställer enhetliga luftflödesmönster som eliminerar heta punkter, kalla zoner och turbulens som kan orsaka målningsfel eller ojämn täckning. Miljöövervakningsfunktionerna från denna tillverkare av lackskåp för bilmålning inkluderar realtidsloggning och aviseringssystem som informerar operatörer om avvikelser från optimala förhållanden, vilket möjliggör omedelbar korrigerande åtgärd för att förhindra kvalitetsproblem med färgen.