Modern automotive and industrial painting operations demand precision, efficiency, and superior finish quality that can only be achieved through advanced equipment solutions. An electric paint booth represents a significant technological advancement in spray painting applications, offering manufacturers and service providers unprecedented control over their coating processes. These sophisticated systems integrate electrical heating elements with advanced ventilation technology to create optimal painting environments that consistently deliver professional-grade results while minimizing waste and environmental impact.

The implementation of an electric paint booth transforms traditional painting operations by providing precise temperature control, enhanced airflow management, and superior containment capabilities. Unlike conventional spray environments, these systems maintain consistent atmospheric conditions that are crucial for achieving uniform coating application and optimal curing characteristics. Professional painters and industrial facilities increasingly rely on electric paint booth technology to meet stringent quality standards while reducing operational costs and improving workplace safety conditions.

Understanding the comprehensive benefits and operational advantages of electric paint booth systems enables informed decision-making for businesses seeking to upgrade their painting capabilities. From enhanced overspray control to improved finish consistency, these advanced systems address critical challenges faced by automotive repair shops, manufacturing facilities, and custom coating operations. The following comprehensive analysis explores how electric paint booth technology revolutionizes modern painting processes and delivers measurable improvements in both quality and efficiency.

Advanced Overspray Control Technologies

Precision Airflow Management Systems

Electric paint booth designs incorporate sophisticated airflow management systems that create laminar flow patterns specifically engineered to capture and contain overspray particles. These systems utilize strategically positioned intake and exhaust fans that maintain consistent air velocity throughout the painting chamber, ensuring that atomized paint particles are efficiently directed toward filtration systems rather than settling on surfaces or escaping into the surrounding environment. The controlled airflow eliminates turbulence that can cause overspray redistribution and ensures uniform air movement from ceiling to floor.

The integration of variable speed controls allows operators to adjust airflow rates based on specific project requirements, paint viscosity, and application methods. This adaptability ensures optimal capture efficiency for different coating materials while maintaining energy efficiency during extended operation periods. Advanced electric paint booth systems feature multi-stage filtration that progressively removes particles of varying sizes, achieving capture rates exceeding 99% for most industrial coating applications.

Intelligent Containment Barriers

Modern electric paint booth construction utilizes specialized barrier materials and sealing systems that create complete containment environments for spray painting operations. These barriers incorporate anti-static properties and smooth surface finishes that prevent paint adhesion while facilitating easy cleaning and maintenance procedures. The sealed environment prevents cross-contamination between different coating projects and eliminates the risk of external contaminants affecting finish quality.

The containment design includes pressure differential monitoring that maintains slight negative pressure within the booth relative to surrounding areas, ensuring that any air leakage flows inward rather than allowing overspray to escape. This pressure control system works in conjunction with door seals and access point barriers to create a completely isolated painting environment that protects both the work area and adjacent facilities from coating contamination.

Temperature Control and Heating Systems

Precision Electric Heating Elements

The electric heating system represents the core advantage of modern electric paint booth technology, providing precise temperature control that directly impacts coating application quality and curing performance. These systems utilize high-efficiency electric heating elements positioned strategically throughout the booth to ensure uniform temperature distribution without creating hot spots or thermal gradients that could affect paint flow characteristics. The electric heating approach eliminates combustion-related concerns while providing instant temperature adjustment capabilities.

Temperature uniformity within ±2°F throughout the booth chamber ensures consistent paint viscosity and application characteristics, resulting in uniform coating thickness and appearance. The electric heating system responds rapidly to temperature setpoint changes, allowing operators to optimize conditions for different coating materials and application techniques. This precision control enables the use of advanced coating formulations that require specific temperature ranges for optimal performance and appearance.

Energy-Efficient Heat Distribution

Advanced electric paint booth designs incorporate sophisticated heat distribution systems that maximize energy efficiency while maintaining optimal operating conditions. These systems utilize forced air circulation combined with radiant heating elements to achieve rapid heat-up times and maintain consistent temperatures throughout extended operation periods. The integration of insulation materials and thermal barriers minimizes heat loss and reduces energy consumption compared to traditional heating methods.

Smart temperature control systems continuously monitor booth conditions and adjust heating output to maintain optimal temperatures while minimizing energy waste. These systems include programmable temperature profiles that can automatically adjust conditions based on coating schedules and operational requirements, reducing manual intervention while ensuring consistent performance across different projects and operating conditions.

Enhanced Finish Quality Achievements

Uniform Coating Application Environment

The controlled environment within an electric paint booth creates ideal conditions for achieving consistent, high-quality coating application that meets or exceeds professional standards. Stable temperature and humidity conditions prevent coating defects such as orange peel, runs, sags, and solvent popping that commonly occur in uncontrolled painting environments. The elimination of temperature fluctuations ensures predictable paint flow characteristics and optimal atomization performance throughout the application process.

Consistent environmental conditions enable the use of advanced coating formulations and application techniques that require precise atmospheric control for optimal performance. The electric paint booth environment supports the application of high-solids coatings, waterborne systems, and specialized industrial finishes that deliver superior durability and appearance characteristics when applied under controlled conditions.

Contamination Prevention Systems

Electric paint booth designs incorporate comprehensive contamination prevention measures that protect coating surfaces from dust, debris, and other airborne particles that can compromise finish quality. The filtration systems include multiple stages of progressively finer filtration media that remove particles ranging from large debris to submicron contaminants. This multi-stage approach ensures that incoming air meets cleanroom standards while maintaining adequate airflow rates for effective overspray capture.

The positive pressure differential maintained in the booth relative to adjacent areas prevents the infiltration of external contaminants while the sealed construction eliminates pathways for dust and debris entry. Advanced systems include air quality monitoring that continuously tracks particulate levels and automatically adjusts filtration system operation to maintain optimal cleanliness standards throughout the painting process.

Operational Efficiency and Productivity Benefits

Rapid Processing Capabilities

Electric paint booth systems significantly reduce processing times through rapid heat-up capabilities and optimized cure cycles that accelerate project completion without compromising quality. The instant-on heating system eliminates lengthy warm-up periods associated with combustion-based heating, allowing immediate commencement of painting operations when needed. This responsiveness enables efficient scheduling and improved throughput for high-volume operations.

The ability to maintain consistent operating conditions throughout extended production runs eliminates the delays associated with temperature recovery and stabilization that occur with less sophisticated systems. Operators can maintain continuous production schedules while achieving consistent quality standards across all processed items, resulting in improved productivity and reduced labor costs per finished unit.

Automated Control Integration

Modern electric paint booth systems incorporate advanced automation capabilities that reduce manual intervention while ensuring consistent operation according to predetermined parameters. Programmable logic controllers manage heating, ventilation, and safety systems automatically, reducing operator workload while maintaining optimal conditions for each specific coating application. These automated systems include recipe storage capabilities that allow operators to recall proven settings for different coating materials and application requirements.

Integration with facility management systems enables remote monitoring and control of booth operations, allowing supervisory personnel to track performance metrics and operational status from central control locations. This connectivity supports predictive maintenance scheduling and performance optimization while providing detailed operational data for process improvement and quality assurance documentation.

Safety and Compliance Advantages

Electrical Safety Systems

Electric paint booth designs incorporate comprehensive electrical safety measures that eliminate ignition sources while providing reliable operation in solvent-rich environments. All electrical components feature explosion-proof construction and intrinsically safe designs that prevent spark generation or surface heating that could ignite flammable vapors. Ground fault protection and electrical isolation systems provide additional safety margins while ensuring continuous operation reliability.

The elimination of open flames and combustion processes inherent in electric heating systems reduces fire risk while simplifying safety compliance requirements. Automated safety monitoring systems continuously track electrical system performance and environmental conditions, providing immediate shutdown capabilities if potentially hazardous conditions are detected.

Environmental Compliance Features

Electric paint booth systems include advanced emission control technologies that ensure compliance with environmental regulations while minimizing operational impact on surrounding communities. The sophisticated filtration and containment systems capture volatile organic compounds and particulate emissions, reducing environmental discharge to levels that meet or exceed regulatory requirements. These systems support the use of environmentally compliant coating formulations while maintaining high-quality finish standards.

Automated monitoring and documentation systems track emission levels and operational parameters, providing the detailed records required for regulatory compliance reporting. The integration of emission control systems with booth operation ensures that environmental protection measures operate effectively throughout all phases of the painting process without compromising productivity or quality standards.

Economic and Long-Term Value Considerations

Cost-Effective Operation Analysis

The operational economics of electric paint booth systems demonstrate significant advantages over alternative heating and ventilation approaches through reduced energy consumption and lower maintenance requirements. Electric heating systems achieve higher energy conversion efficiency compared to combustion-based alternatives while eliminating fuel storage and delivery costs. The precise control capabilities reduce coating material waste through improved transfer efficiency and reduced rework requirements.

Long-term operational costs benefit from the reliability and durability of electric paint booth components, which typically require less frequent maintenance and replacement compared to combustion systems. The elimination of fuel-related maintenance issues and the reduced complexity of electric systems contribute to lower total cost of ownership while providing more predictable operational expenses for budget planning purposes.

Return on Investment Factors

Investment in electric paint booth technology generates measurable returns through improved productivity, reduced waste, and enhanced quality consistency that commands premium pricing for finished products. The reduction in rework and rejection rates directly impacts profitability while the improved finish quality enables access to higher-value market segments. Faster processing times and improved throughput increase facility capacity without requiring additional floor space or personnel.

The enhanced safety and compliance capabilities of electric paint booth systems reduce insurance costs and regulatory compliance expenses while minimizing the risk of costly shutdowns or penalties. These risk mitigation benefits contribute significantly to the overall economic value of electric paint booth investments, particularly for facilities handling high-value products or operating under stringent regulatory oversight.

FAQ

What maintenance requirements are associated with electric paint booth systems?

Electric paint booth systems require routine filter replacement, heating element inspection, and electrical system testing to maintain optimal performance. Regular cleaning of booth surfaces and ventilation components prevents contamination buildup while periodic calibration of temperature and airflow controls ensures consistent operation. Most maintenance tasks can be performed by facility personnel following manufacturer guidelines, reducing dependence on specialized service contractors.

How do electric paint booth systems compare to gas-heated alternatives in terms of operating costs?

Electric paint booth systems typically demonstrate lower total operating costs due to higher energy conversion efficiency, reduced maintenance requirements, and elimination of fuel handling expenses. While electricity costs may vary by region, the precision control capabilities and improved transfer efficiency often result in material savings that offset energy expenses. The reduced complexity and higher reliability of electric systems contribute to lower long-term operational costs.

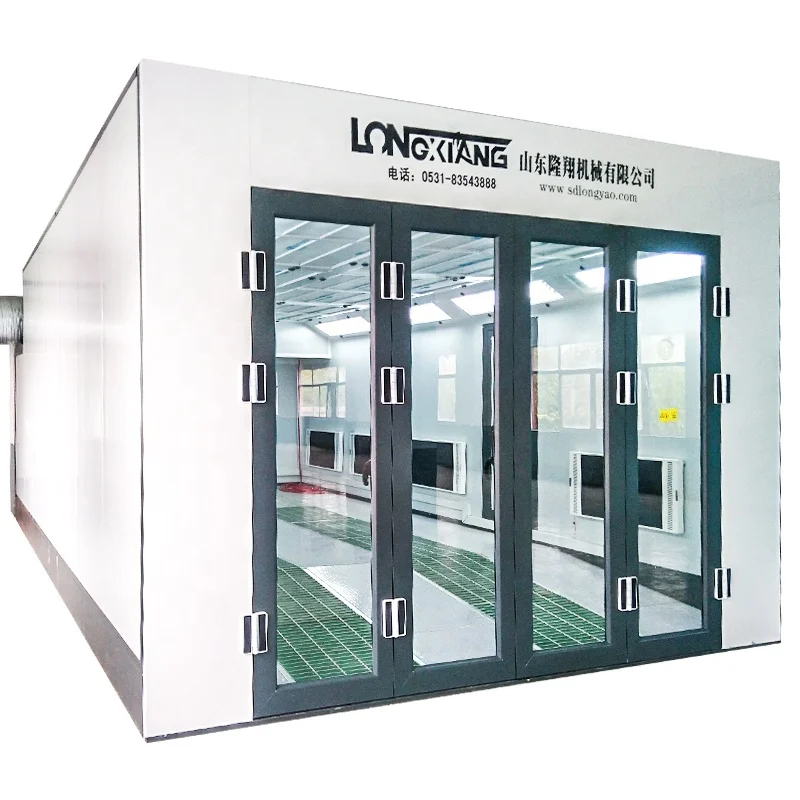

What size and configuration options are available for electric paint booth installations?

Electric paint booth systems are available in various sizes and configurations to accommodate different applications, from small automotive repair operations to large industrial manufacturing facilities. Standard configurations include drive-through, side-loading, and walk-in designs with customizable dimensions to fit specific facility requirements and workflow patterns. Modular construction approaches allow for future expansion while specialized configurations address unique operational requirements.

How quickly can an electric paint booth reach optimal operating temperature?

Electric paint booth heating systems typically achieve optimal operating temperature within 15-30 minutes depending on booth size and ambient conditions. The instant-on capability of electric heating eliminates lengthy warm-up periods while programmable controls allow automated heating cycles to prepare the booth for scheduled operations. This rapid response capability significantly improves operational efficiency compared to combustion-based heating systems that require longer stabilization periods.

Table of Contents

- Advanced Overspray Control Technologies

- Temperature Control and Heating Systems

- Enhanced Finish Quality Achievements

- Operational Efficiency and Productivity Benefits

- Safety and Compliance Advantages

- Economic and Long-Term Value Considerations

-

FAQ

- What maintenance requirements are associated with electric paint booth systems?

- How do electric paint booth systems compare to gas-heated alternatives in terms of operating costs?

- What size and configuration options are available for electric paint booth installations?

- How quickly can an electric paint booth reach optimal operating temperature?