The modern woodworking industry demands precision, efficiency, and flawless finishes when it comes to cabinet and interior door manufacturing. A door paint booth has revolutionized how manufacturers approach the finishing process, transforming traditional spray painting methods into sophisticated, controlled environments that deliver consistent results. These specialized enclosures provide the ideal conditions for applying various coatings while maintaining dust-free environments and optimal airflow patterns that ensure professional-grade outcomes.

Manufacturing facilities worldwide have recognized the transformative impact of implementing dedicated finishing systems for their door production lines. The controlled environment created by these booths eliminates many variables that traditionally compromised finish quality, while simultaneously improving production throughput and worker safety standards. Understanding the comprehensive benefits and operational aspects of door paint booth systems enables manufacturers to make informed decisions about upgrading their finishing capabilities.

Understanding Door Paint Booth Technology

Core Components and Design Features

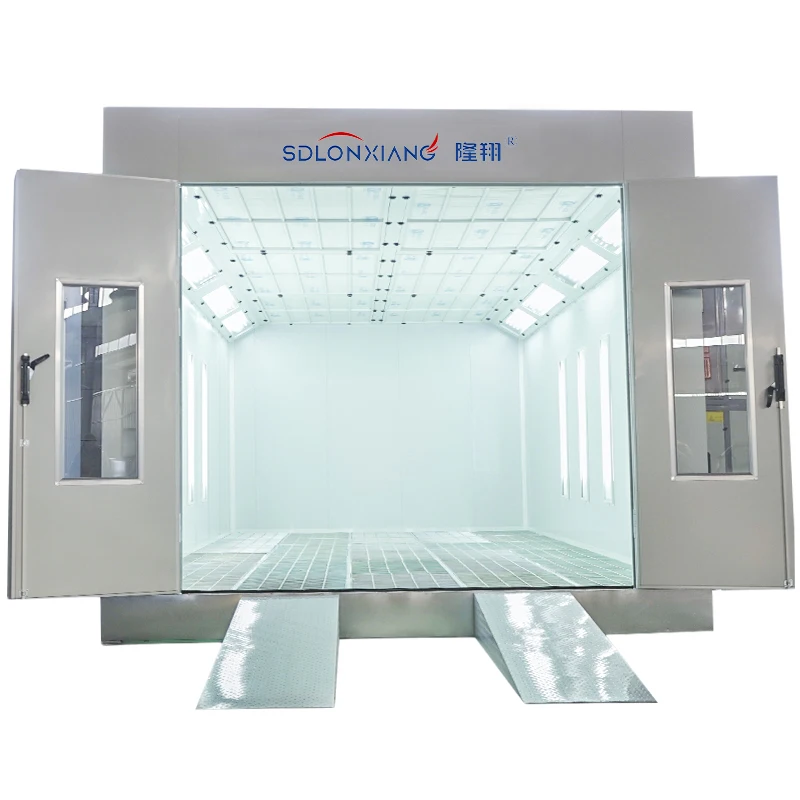

Modern door paint booth systems incorporate sophisticated ventilation technology that creates precise airflow patterns essential for achieving uniform coating distribution. The booth structure typically features reinforced steel construction with interior surfaces designed to minimize particle accumulation and facilitate easy cleaning. Advanced filtration systems work continuously to capture overspray particles and maintain the pristine environment necessary for high-quality finishes.

Temperature and humidity control mechanisms within a door paint booth ensure optimal curing conditions for various coating materials. These systems maintain consistent environmental parameters that prevent common finishing defects such as orange peel texture, runs, or inadequate adhesion. The integration of LED lighting systems provides uniform illumination that allows operators to identify potential issues during application and ensures color accuracy throughout the finishing process.

Airflow Dynamics and Contamination Control

The engineered airflow patterns in professional door paint booth installations create laminar flow conditions that carry overspray particles away from work surfaces. This downward airflow design prevents contamination from settling on freshly painted surfaces while maintaining consistent pressure differentials that keep external contaminants from entering the workspace. The sophisticated filtration hierarchy typically includes pre-filters, primary filters, and exhaust filters that work together to maintain air quality standards.

Contamination control extends beyond airflow management to include specialized floor systems designed to capture fallen particles and prevent their recirculation. Many door paint booth configurations incorporate sticky or tacky floor coverings that trap dust and debris, while others utilize grated flooring systems that allow particles to fall into collection areas below the workspace. These design elements work synergistically to create the ultra-clean environment essential for achieving mirror-like finishes on cabinet and interior doors.

Production Efficiency Advantages

Streamlined Workflow Integration

Implementation of a dedicated door paint booth creates opportunities for establishing efficient production workflows that minimize handling time and reduce the risk of damage between process stages. The contained environment allows for strategic positioning of material handling equipment, curing stations, and quality control checkpoints that optimize the movement of doors through the finishing sequence. This systematic approach reduces bottlenecks and enables higher throughput rates compared to traditional open-spray finishing methods.

The controlled environment within the booth also facilitates batch processing techniques that maximize equipment utilization and reduce setup times between different door styles or finish specifications. Manufacturers can group similar products together to minimize color changes and coating adjustments, while the consistent environmental conditions ensure uniform results across entire production runs. This operational efficiency translates directly into reduced labor costs and improved delivery schedules.

Quality Consistency and Reduced Rework

The elimination of environmental variables within a door paint booth dramatically reduces the occurrence of finish defects that require costly rework or product rejection. Consistent temperature, humidity, and airflow conditions create predictable coating behavior that allows operators to achieve repeatable results with minimal variation. This reliability is particularly valuable when working with premium cabinet doors or custom interior doors where finish quality directly impacts perceived value.

Documentation and process control capabilities integrated into modern door paint booth systems enable manufacturers to track and analyze finishing parameters for continuous improvement initiatives. Digital monitoring systems can record environmental conditions, coating consumption rates, and cycle times to identify optimization opportunities and ensure compliance with quality standards. This data-driven approach to process management supports lean manufacturing principles and helps justify equipment investments through measurable performance improvements.

Material and Coating Compatibility

Solvent-Based Coating Applications

Professional door paint booth systems excel at handling solvent-based coatings that require precise environmental control for optimal application and curing characteristics. The explosion-proof electrical systems and proper ventilation rates ensure safe handling of flammable materials while maintaining the low-contamination environment necessary for achieving glass-smooth finishes. Advanced booth designs incorporate specialized heating systems that accelerate solvent evaporation and reduce cure times without compromising coating integrity.

The controlled atmosphere within the booth prevents solvent entrapment that can lead to soft finishes or poor adhesion between coating layers. Precise temperature ramping capabilities allow operators to follow manufacturer-recommended curing schedules that optimize coating performance characteristics such as hardness, chemical resistance, and durability. This level of process control is essential when applying high-performance coatings to doors that will experience heavy use or exposure to moisture and cleaning chemicals.

Water-Based and Environmentally Friendly Finishes

The versatility of modern door paint booth technology extends to water-based and low-VOC coating systems that require different environmental parameters than traditional solvent-based materials. Humidity control becomes particularly critical when working with water-based finishes, as excessive moisture can interfere with proper coalescence and film formation. The booth systems can be programmed to maintain optimal humidity levels that promote proper drying while preventing defects such as blushing or poor flow characteristics.

Temperature management for water-based coatings often requires different profiles than solvent systems, with gradual warming cycles that prevent rapid moisture evaporation and the associated surface defects. The flexibility of door paint booth environmental controls enables manufacturers to optimize conditions for specific coating chemistries, ensuring maximum performance from environmentally compliant finishing materials. This adaptability becomes increasingly valuable as industry regulations continue to favor low-emission coating systems.

Safety and Regulatory Compliance

Worker Protection and Health Standards

Implementation of a properly designed door paint booth significantly reduces worker exposure to hazardous coating materials and solvents through engineered containment and ventilation systems. The negative pressure environment prevents overspray particles and vapors from escaping into adjacent work areas, while personal protective equipment requirements can often be reduced due to the improved environmental controls. This enhanced safety profile reduces liability concerns and supports compliance with occupational health regulations.

Emergency response capabilities built into modern booth systems include automatic fire suppression systems, emergency ventilation modes, and fail-safe controls that prioritize worker safety in the event of equipment malfunctions. Regular maintenance protocols ensure that safety systems remain functional and that air quality standards are consistently maintained. These comprehensive safety measures create a more attractive work environment that can help with employee retention and reduce insurance costs associated with finishing operations.

Environmental Compliance and Emission Control

Sophisticated filtration and emission control systems integrated into door paint booth installations help manufacturers meet increasingly stringent environmental regulations governing VOC emissions and particulate discharge. The multi-stage filtration hierarchy captures overspray particles with high efficiency, while thermal or catalytic oxidizers can be incorporated to destroy volatile organic compounds before they are released to the atmosphere. This comprehensive approach to emission control often eliminates the need for expensive off-site disposal of contaminated filters and waste materials.

Documentation capabilities built into modern booth control systems provide the detailed records necessary for regulatory compliance reporting and environmental audits. Automated monitoring of key parameters such as airflow rates, filter pressure differentials, and emission concentrations creates audit trails that demonstrate ongoing compliance with permit conditions. This systematic approach to environmental management reduces regulatory risk and can support applications for operating permits or modifications to existing facilities.

Cost Analysis and Return on Investment

Initial Investment Considerations

The capital investment required for a door paint booth installation varies significantly based on booth size, environmental control sophistication, and automation level, but the long-term benefits typically justify the initial expenditure. Factors influencing cost include booth dimensions, filtration system complexity, heating and cooling capacity, and integration with existing production equipment. While the upfront investment may be substantial, the operational improvements and quality enhancements often generate positive returns within the first few years of operation.

Financing options and equipment leasing programs can help manufacturers acquire door paint booth systems without depleting working capital reserves. Many suppliers offer comprehensive packages that include installation, training, and ongoing support services that simplify the implementation process and ensure optimal performance from day one. The availability of government incentives for environmental improvements or energy-efficient equipment can further improve the financial attractiveness of booth investments.

Operational Cost Benefits

The operational cost advantages of door paint booth systems become apparent through reduced material waste, lower rework rates, and improved production efficiency. The controlled environment minimizes coating overspray and contamination that leads to rejected products, while consistent environmental conditions reduce the variability that necessitates process adjustments and material reformulation. These efficiency gains translate directly into lower per-unit finishing costs and improved profit margins.

Energy consumption in well-designed door paint booth systems can be optimized through heat recovery systems, variable-speed fans, and programmable environmental controls that match energy usage to production requirements. The elimination of heating costs for large factory spaces during finishing operations can generate significant savings, particularly in climate-controlled facilities. Additionally, the reduced insurance premiums and regulatory compliance costs associated with improved safety and environmental performance contribute to the overall cost benefits of booth installation.

FAQ

What types of doors can be finished in a door paint booth

A door paint booth can accommodate various door types including solid wood cabinet doors, engineered wood interior doors, MDF cabinet fronts, and composite door materials. The booth size and configuration determine the maximum door dimensions that can be processed, with most commercial installations capable of handling standard residential and commercial door sizes. The controlled environment benefits all door materials by ensuring consistent finish quality regardless of the substrate material or coating system used.

How does booth size affect production capacity

Door paint booth size directly impacts production throughput by determining how many doors can be processed simultaneously and the efficiency of material handling operations. Larger booths allow for batch processing of multiple doors or accommodation of automated finishing equipment that increases output rates. However, booth size must be balanced against energy consumption and space requirements, with optimal sizing based on specific production volumes and door dimensions typical for the facility.

What maintenance requirements are involved with door paint booth operation

Regular maintenance of a door paint booth includes filter replacement, cleaning of interior surfaces, calibration of environmental controls, and inspection of safety systems. Filter replacement frequency depends on production volume and coating types, typically ranging from weekly to monthly intervals for primary filters. Preventive maintenance schedules should include quarterly deep cleaning, annual system calibrations, and regular testing of fire suppression and emergency systems to ensure optimal performance and regulatory compliance.

Can existing facilities be retrofitted with door paint booth systems

Most existing manufacturing facilities can be successfully retrofitted with door paint booth installations, though structural modifications may be required to accommodate ventilation systems and utilities. Retrofit considerations include ceiling height, floor load capacity, electrical service availability, and space for air handling equipment. Professional assessment of existing facilities can identify any necessary modifications and develop implementation plans that minimize production disruption during installation.