Investing in a professional furniture spray booth represents a significant financial commitment that can transform your woodworking or furniture manufacturing operation. These specialized environments provide controlled conditions for applying finishes, stains, and protective coatings to furniture pieces while ensuring consistent quality and regulatory compliance. Understanding the various cost factors involved in purchasing and installing a furniture spray booth will help you make an informed decision that aligns with your budget and production requirements.

The initial purchase price of a furniture spray booth varies significantly based on size, features, and manufacturer specifications. Entry-level models suitable for small shops typically start around $15,000 to $25,000, while mid-range systems designed for moderate production volumes can cost between $30,000 and $60,000. High-end industrial furniture spray booths with advanced filtration systems, automated controls, and larger capacities often exceed $100,000. These price ranges reflect the booth structure itself and basic components, but additional costs for installation, electrical work, and ventilation modifications can substantially increase the total investment.

Beyond the equipment cost, facility preparation and installation expenses add considerable value to your project budget. Professional installation typically requires specialized contractors familiar with spray booth regulations and safety requirements. Labor costs for installation generally range from $5,000 to $15,000, depending on the complexity of your chosen system and existing facility conditions. Electrical modifications to support the booth's power requirements, including adequate amperage for heating elements, fans, and control systems, often cost an additional $3,000 to $8,000.

Equipment Specifications and Pricing Factors

Size and Capacity Considerations

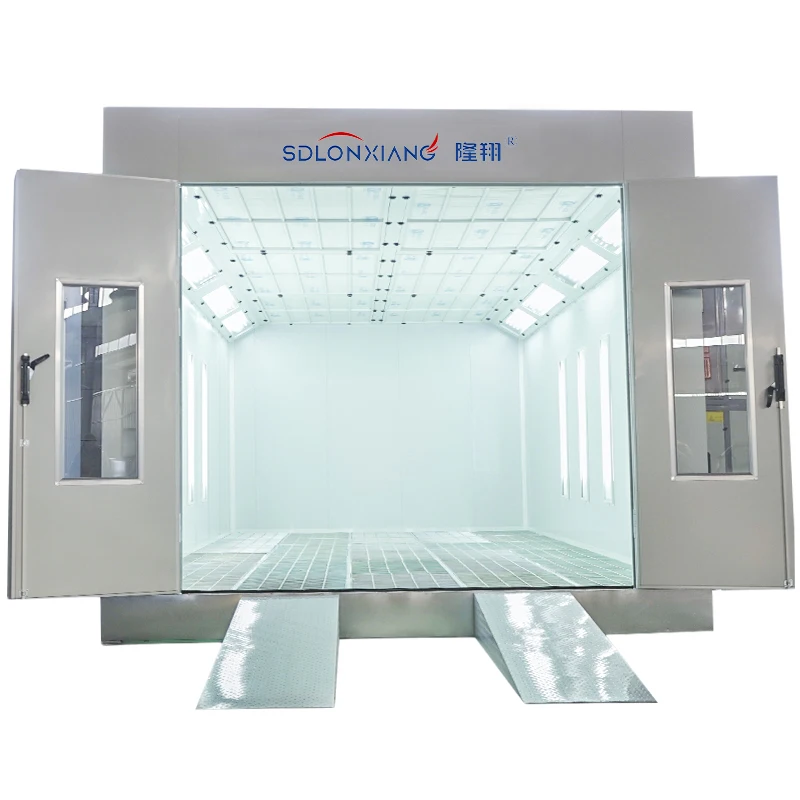

The dimensions of your furniture spray booth directly impact both purchase price and installation costs. Standard residential furniture pieces require booths measuring approximately 14 feet wide by 9 feet deep by 9 feet high, while commercial operations handling larger items like dining tables or bedroom sets need expanded dimensions up to 24 feet in length. Smaller booths designed for chair refinishing or cabinet work start around $20,000, while larger systems capable of accommodating full furniture suites can cost $45,000 to $75,000 before installation.

Custom sizing options are available from most manufacturers but typically add 15% to 30% to the base price. Consider your largest typical workpieces when selecting dimensions, as upgrading to a larger booth later proves more expensive than initial investment in adequate capacity. The booth's height affects both material costs and installation complexity, particularly regarding exhaust fan placement and ductwork routing through your facility's roof structure.

Filtration and Ventilation Systems

Advanced filtration technology significantly influences furniture spray booth pricing while ensuring compliance with environmental regulations. Basic dry filter systems using disposable media cost less initially but require ongoing replacement expenses that can total $2,000 to $4,000 annually depending on usage volume. Wet scrubber systems, while more expensive upfront, offer superior overspray capture and reduced filter replacement costs over the long term.

High-efficiency particulate air (HEPA) filtration adds approximately $8,000 to $12,000 to the base booth price but provides exceptional air quality control essential for premium furniture finishing. The ventilation system's capacity, measured in cubic feet per minute (CFM), must match your booth size and local code requirements. Adequate airflow ensures proper overspray removal and maintains safe solvent vapor concentrations below explosive limits.

Installation Requirements and Associated Costs

Foundation and Structural Preparation

Proper foundation preparation ensures stable operation and longevity of your furniture spray booth investment. Most installations require a level concrete pad with adequate drainage and utility access points. Foundation work typically costs $3,000 to $7,000 depending on site conditions and local labor rates. Existing concrete floors may need modification for anchor bolts and utility trenches, adding $1,500 to $3,500 to preparation costs.

Structural considerations include adequate ceiling height for exhaust ductwork and sufficient floor space for booth placement plus operator movement. Some facilities require roof modifications or structural reinforcement to support exhaust fan mounting, particularly for larger systems with substantial airflow requirements. These modifications can add $5,000 to $15,000 to your project depending on existing building conditions.

Utility Connections and Compliance

Connecting utilities to your furniture spray booth requires careful planning and professional installation to ensure safe operation. Electrical connections for heating elements, lighting, and ventilation fans typically require 480-volt three-phase service with adequate amperage capacity. Electrical installation costs range from $4,000 to $10,000 depending on distance from your main panel and required upgrades.

Natural gas connections for heating systems add approximately $2,000 to $5,000 in installation costs, while compressed air lines for spray equipment require additional plumbing work costing $1,000 to $3,000. Fire suppression system integration, often mandated by local codes, can add $8,000 to $15,000 but provides essential safety protection for your investment and facility.

Operating Costs and Long-term Considerations

Energy Consumption and Efficiency

Monthly operating costs for furniture spray booths include electricity for lighting, ventilation, and heating systems. Typical energy consumption ranges from $400 to $1,200 per month depending on booth size, usage patterns, and local utility rates. Energy-efficient LED lighting and variable-speed drive fans can reduce consumption by 20% to 30% compared to conventional systems, though these upgrades increase initial purchase prices by $3,000 to $6,000.

Heating costs vary significantly with climate and booth usage frequency. Gas-fired heating systems generally offer lower operating costs than electric alternatives in most regions. Heat recovery systems, while adding $5,000 to $8,000 to initial costs, can reduce heating expenses by capturing waste heat from exhaust air and preheating incoming fresh air during cold weather operation.

Maintenance and Filter Replacement

Regular maintenance ensures optimal performance and extends furniture spray booth lifespan while controlling long-term operating expenses. Filter replacement represents the largest ongoing cost, typically ranging from $150 to $400 per month depending on booth size and production volume. High-volume operations may require weekly filter changes, while smaller shops might replace filters monthly or bi-monthly.

Annual maintenance contracts from qualified service providers cost approximately $2,000 to $5,000 but include regular inspections, belt replacements, and minor repairs. These contracts often provide priority service response and can help maintain warranty coverage on major components. Preventive maintenance reduces unexpected downtime and extends equipment life, making professional service contracts a worthwhile investment for most operations.

Financing Options and Return on Investment

Equipment Financing and Leasing

Many furniture manufacturers and finishing shops utilize equipment financing to spread furniture spray booth costs over multiple years while preserving working capital. Equipment loans typically offer terms from 3 to 7 years with interest rates ranging from 6% to 12% depending on credit qualifications and loan amount. Monthly payments for a $50,000 system might range from $800 to $1,400 depending on terms and down payment.

Leasing arrangements provide an alternative for businesses preferring predictable monthly expenses without ownership responsibilities. Lease payments typically range from 2% to 4% of equipment value monthly, with options to purchase at lease end. Some lease agreements include maintenance coverage, simplifying budgeting and reducing unexpected repair expenses during the lease term.

Productivity and Quality Benefits

Professional furniture spray booths justify their cost through improved finishing quality, increased production capacity, and enhanced worker safety. Controlled environments eliminate dust contamination and provide consistent temperature and humidity conditions essential for premium finishes. These improvements often allow shops to charge premium prices for superior quality work, improving profit margins on finishing services.

Time savings from faster cure times and reduced rework contribute significantly to return on investment calculations. Heated booths can reduce cure times by 50% to 70% compared to ambient air drying, allowing faster job completion and improved customer satisfaction. Reduced material waste from better transfer efficiency and fewer defects further improves profitability over time.

Regulatory Compliance and Safety Considerations

Environmental Regulations and Permits

Installing a furniture spray booth requires compliance with various environmental regulations and may necessitate air quality permits from local authorities. Permit costs typically range from $500 to $3,000 depending on booth size and local requirements. Some jurisdictions require annual emissions testing or reporting, adding ongoing compliance costs of $1,000 to $2,500 annually.

Volatile organic compound (VOC) emissions controls may require additional equipment such as thermal oxidizers or carbon adsorption systems for high-volume operations. These add-on systems can cost $15,000 to $50,000 but ensure compliance with strict air quality regulations while protecting your business from potential fines or operational restrictions.

Safety Equipment and Insurance

Safety equipment requirements add to furniture spray booth installation costs but provide essential protection for workers and facilities. Explosion-proof electrical components, emergency shut-off systems, and fire suppression equipment typically add $5,000 to $12,000 to base installation costs. These safety features often reduce insurance premiums and may be required by local fire codes or insurance carriers.

Insurance considerations include coverage for the booth equipment itself plus liability protection for finishing operations. Premium increases for spray booth operations typically range from $2,000 to $6,000 annually depending on coverage limits and carrier requirements. Some insurers offer discounts for facilities with modern safety equipment and proper operator training programs.

FAQ

What factors most significantly affect furniture spray booth pricing

The primary factors influencing furniture spray booth costs include booth dimensions, filtration system complexity, heating method, and control automation level. Larger booths naturally cost more due to increased materials and structural requirements. Advanced filtration systems with HEPA filters or wet scrubbing technology add substantial costs but provide superior air quality control. Heated booths cost more initially but offer faster cure times and year-round operation capability.

How long does furniture spray booth installation typically take

Professional furniture spray booth installation usually requires 2 to 4 weeks from delivery to operational status, depending on site preparation requirements and utility modifications needed. Simple installations in prepared facilities with adequate utilities might complete in 1 to 2 weeks, while complex projects requiring foundation work, electrical upgrades, or structural modifications can extend to 6 weeks or longer. Weather conditions and permit approval times can also affect installation schedules.

What ongoing maintenance costs should be expected

Annual maintenance costs for furniture spray booths typically range from $3,000 to $8,000 including filter replacements, belt changes, and routine inspections. High-volume operations with daily use may experience higher filter replacement costs, while occasional users might spend less on consumables. Professional maintenance contracts cost $2,000 to $5,000 annually but often provide cost savings through preventive care and priority service response.

Can existing buildings accommodate furniture spray booth installation

Most existing industrial buildings can accommodate furniture spray booth installation with appropriate modifications. Key requirements include adequate ceiling height for exhaust ductwork, sufficient electrical capacity for booth operations, and proper ventilation access to exterior walls or roof. Older buildings may require structural reinforcement or electrical upgrades adding $10,000 to $25,000 to installation costs, but conversion is usually more economical than constructing new facilities.