Flexible Configuration and Expansion Capabilities

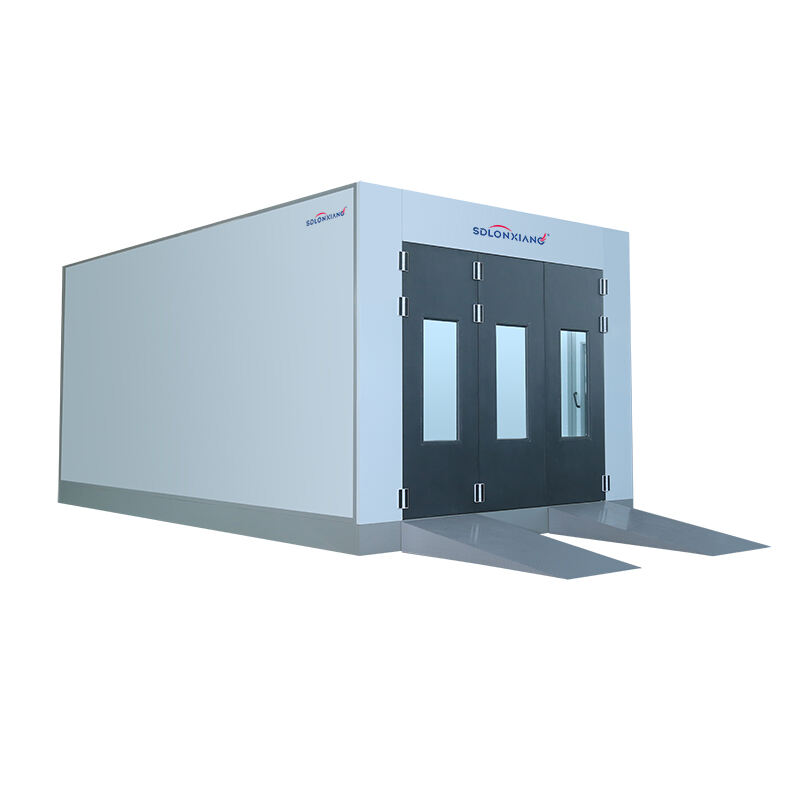

The used car paint booth market offers exceptional flexibility in configuration options that accommodate diverse operational requirements and facility constraints. Standard booth sizes range from compact single-car units suitable for small shops to large multi-bay configurations capable of handling commercial fleet operations. Many used booths feature modular construction that enables expansion or reconfiguration as business needs evolve, providing scalability that grows with operational demands. Prep station integration allows facilities to combine surface preparation and painting operations within a single system, maximizing workflow efficiency and space utilization. Drive-through designs facilitate high-volume operations by enabling continuous vehicle flow without manual repositioning requirements. The used car paint booth can be customized with various door configurations, including bifold, roll-up, or sliding options that match facility layouts and operational preferences. Ceiling height variations accommodate different vehicle types, from standard passenger cars to tall commercial trucks and recreational vehicles. Mobile booth options provide flexibility for operations that require temporary or portable painting capabilities. Many used installations include specialized features such as mixing rooms, equipment storage areas, and operator platforms that enhance functionality and convenience. Electrical configurations can be adapted to match existing facility power supplies, while control systems offer programming flexibility for different painting processes and curing cycles. The booth interior can be modified with additional lighting, compressed air outlets, and tool mounting systems that support specific operational requirements. Foundation requirements vary among different booth types, with some designs suitable for concrete slab installation while others accommodate drive-over pit configurations. Ventilation connections can be adapted to integrate with existing facility exhaust systems or operate as standalone units. The flexibility of used car paint booth systems enables buyers to select equipment that precisely matches their operational needs while maintaining compatibility with existing facility infrastructure and workflow patterns.