Versatile Application Capabilities

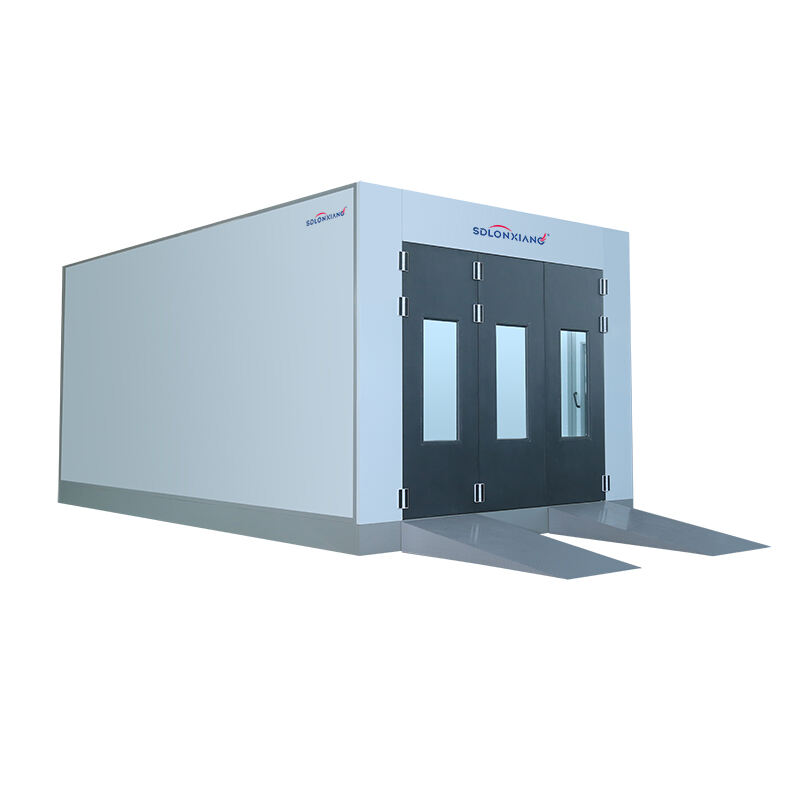

A used automotive paint booth demonstrates remarkable versatility in handling diverse vehicle types and coating applications, making it an invaluable asset for businesses serving varied customer needs and market segments. This adaptability extends beyond standard passenger vehicles to encompass motorcycles, commercial trucks, recreational vehicles, agricultural equipment, and specialty automotive projects requiring professional-grade finishing capabilities. The spacious interior dimensions accommodate vehicles of different sizes while maintaining proper clearances for operator movement and equipment access during all phases of the refinishing process. Adjustable fixture systems enable secure positioning of various vehicle configurations, ensuring optimal spray angles and complete coverage regardless of body style or dimensional variations. The booth design supports multiple coating systems including water-based paints, solvent-based materials, primers, basecoats, clearcoats, and specialty finishes such as texture coatings or protective applications. Temperature and airflow controls adapt to different material requirements, providing optimal conditions for proper application and curing of diverse coating formulations. The ventilation system effectively manages various solvent types and concentrations, maintaining safe working conditions across different paint chemistry platforms. Lighting arrangements provide uniform illumination that reveals surface imperfections and ensures complete coverage during application of any coating type or color. The booth configuration supports both spot repair applications and complete refinishing projects, offering flexibility to handle insurance work, custom painting, fleet maintenance, and restoration services within the same facility. Work flow optimization features accommodate different project timelines and complexity levels, enabling efficient scheduling and resource allocation for maximum productivity. The chemical compatibility of booth materials ensures safe operation with aggressive solvents and specialized coatings used in high-performance applications. Contamination prevention measures protect sensitive finishes during multi-stage application processes, preventing defects that could compromise final appearance or durability. The booth systems support various application methods including conventional spray guns, HVLP equipment, electrostatic systems, and specialized tools for texture or protective coatings. Quality control capabilities enable consistent results across different operators, coating systems, and environmental conditions, supporting business reputation and customer satisfaction objectives.