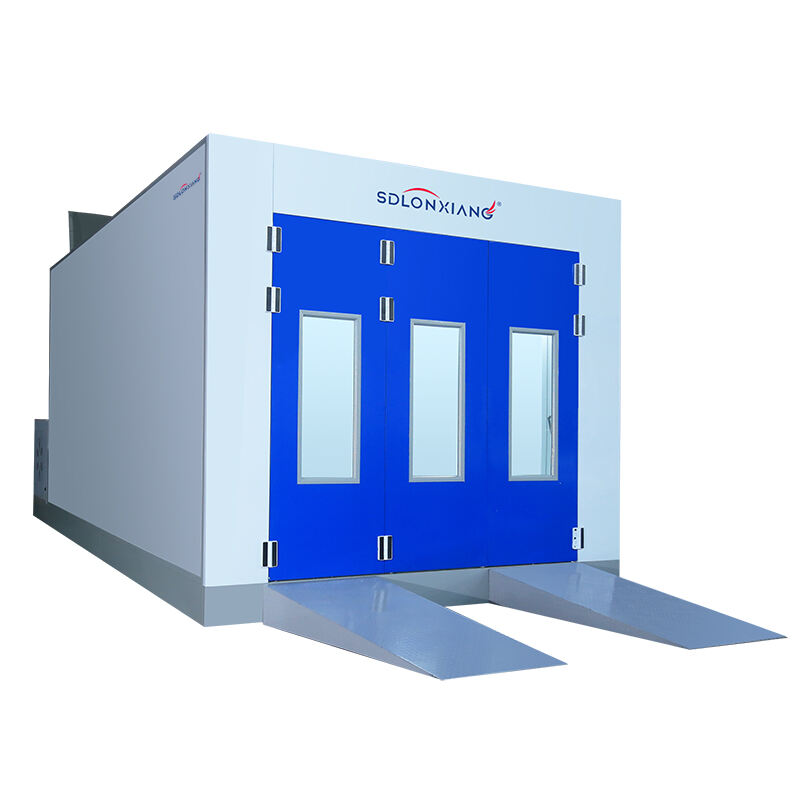

paint booth for sale

A paint booth for sale represents a comprehensive solution for professional automotive refinishing and industrial coating applications. These specialized enclosures provide controlled environments that ensure optimal paint application results while maintaining safety standards and environmental compliance. Modern paint booths incorporate advanced ventilation systems that create precise airflow patterns, effectively capturing overspray and volatile organic compounds before they can contaminate the surrounding workspace or escape into the atmosphere. The primary function of a paint booth for sale involves creating a dust-free environment where temperature, humidity, and air circulation remain consistent throughout the painting process. This controlled atmosphere prevents defects such as dust nibs, orange peel texture, and uneven coating thickness that commonly occur in uncontrolled environments. Technological features of contemporary paint booths include programmable control systems that automatically adjust heating, ventilation, and filtration parameters based on specific coating requirements. Many units feature energy-efficient infrared heating systems that cure coatings faster while consuming less electricity compared to conventional heating methods. Advanced filtration technology removes particulates as small as 0.3 microns, ensuring pristine air quality during application. The applications for paint booths extend beyond automotive repair shops to include manufacturing facilities, furniture refinishing operations, marine vessel coating, aircraft maintenance, and industrial equipment painting. These versatile systems accommodate various coating types including water-based paints, solvent-based finishes, powder coatings, and specialized protective coatings. Professional paint booths for sale typically feature modular designs that allow customization based on specific dimensional requirements and throughput demands. Safety features include explosion-proof lighting, emergency shut-off systems, and fire suppression capabilities that protect operators and valuable equipment from potential hazards associated with flammable coating materials.