paint booth electric

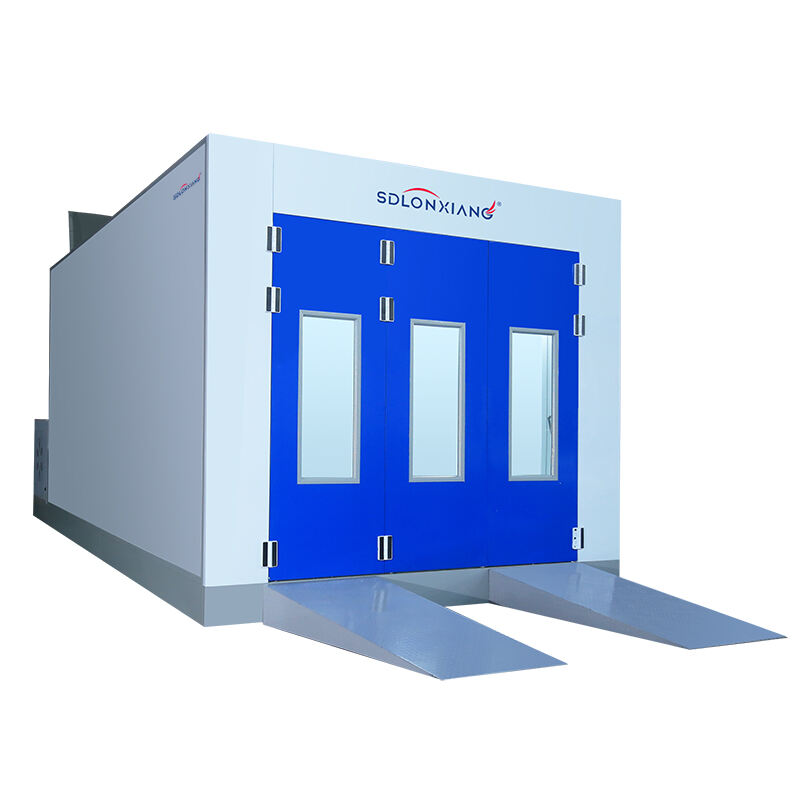

A paint booth electric represents a sophisticated ventilation and filtration system designed specifically for automotive refinishing, industrial coating applications, and manufacturing processes. This advanced equipment creates a controlled environment that ensures optimal paint application while maintaining safety standards and environmental compliance. The paint booth electric operates through a comprehensive air circulation system that draws contaminated air away from the workspace, filters it through multiple stages, and provides clean, temperature-controlled air for superior coating results. Modern paint booth electric systems incorporate state-of-the-art technology including variable speed fans, digital controls, and automated monitoring systems that continuously track air velocity, temperature, and humidity levels. These units feature robust construction with powder-coated steel frames, LED lighting systems for excellent visibility, and explosion-proof electrical components that meet stringent safety regulations. The filtration process typically involves pre-filters that capture larger particles, followed by high-efficiency filters that remove fine contaminants and overspray materials. Advanced paint booth electric models include heat recovery systems that recycle warm air, reducing energy consumption while maintaining optimal operating temperatures. The technological features extend to programmable logic controllers that allow operators to customize airflow patterns, temperature settings, and operational schedules based on specific coating requirements. Applications span across automotive repair shops, manufacturing facilities, aerospace industries, marine coating operations, and custom fabrication workshops. The paint booth electric serves as an essential component for businesses requiring professional-grade finishing capabilities, ensuring consistent quality while protecting workers from harmful vapors and maintaining compliance with environmental regulations. These systems accommodate various project sizes, from small automotive parts to large industrial components, making them versatile solutions for diverse coating needs.