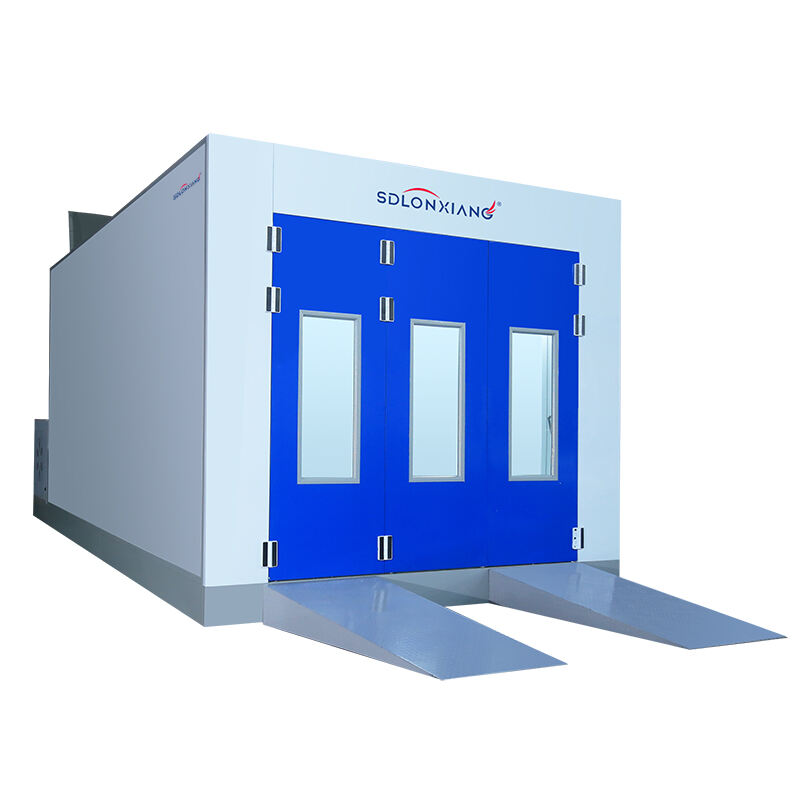

automotive refinish paint booths

Automotive refinish paint booths represent essential equipment in professional collision repair and vehicle restoration facilities. These specialized chambers create controlled environments that ensure superior paint application results while maintaining safety standards throughout the refinishing process. The primary function of automotive refinish paint booths centers on providing clean, temperature-controlled spaces where vehicles receive professional paint treatments without contamination from external particles or environmental factors. These systems incorporate advanced filtration technology that removes airborne contaminants, ensuring pristine surface finishes that meet industry standards. The technological features of automotive refinish paint booths include sophisticated airflow management systems that maintain consistent air circulation patterns, preventing overspray accumulation and ensuring uniform paint distribution. Temperature control mechanisms regulate internal climate conditions, optimizing paint curing processes and reducing application defects. Modern automotive refinish paint booths feature energy-efficient heating systems that maintain precise temperature ranges required for different coating types. Lighting systems within these booths utilize full-spectrum illumination that reveals true color matching capabilities, enabling technicians to achieve accurate paint blends. Applications for automotive refinish paint booths extend beyond basic vehicle repainting to include specialty coatings, custom finishes, and restoration projects. Professional body shops rely on these systems for insurance repair work, while custom shops utilize them for show vehicles and specialty applications. The controlled environment prevents dust contamination, reduces rework requirements, and ensures consistent quality outcomes. Safety features integrated into automotive refinish paint booths include fire suppression systems, explosion-proof components, and proper ventilation that protects workers from harmful vapors. These booths comply with environmental regulations by containing overspray and filtering exhaust air before release. The combination of functionality, safety, and quality control makes automotive refinish paint booths indispensable tools for professional vehicle refinishing operations seeking consistent, high-quality results.