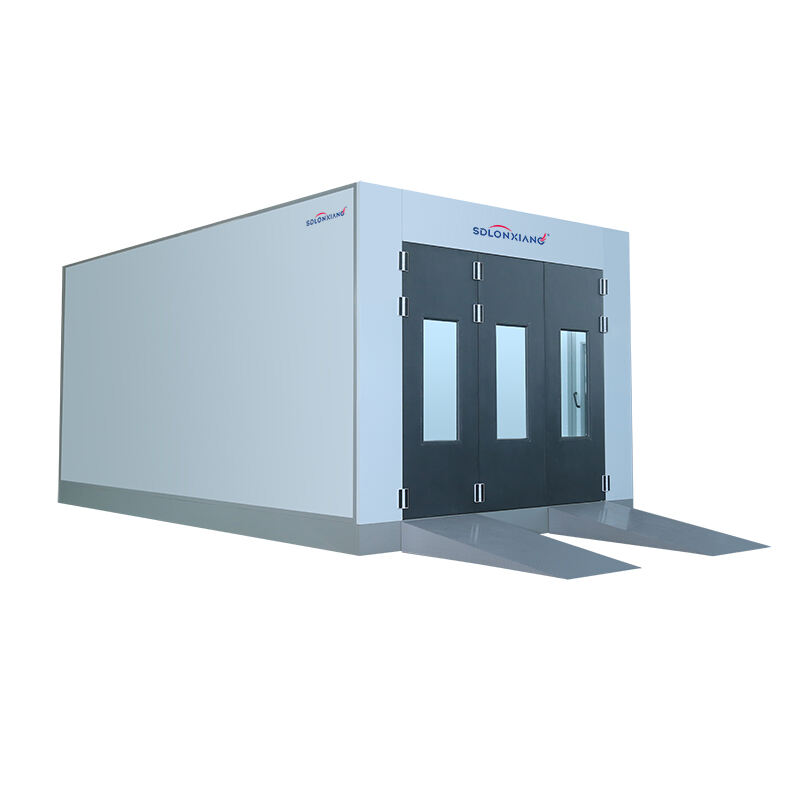

spray booth oven sale

The spray booth oven sale represents a significant opportunity for automotive repair shops, manufacturing facilities, and custom finishing operations to upgrade their paint application and curing systems. These sophisticated units combine the functionality of a paint spray booth with an integrated curing oven, creating a comprehensive solution for professional-grade coating applications. During a spray booth oven sale, customers can access premium equipment featuring advanced ventilation systems, precise temperature controls, and energy-efficient heating mechanisms at competitive prices. The primary functions of these systems include paint application in a controlled environment, contaminant removal through filtered air circulation, and accelerated curing processes that reduce production time. Modern spray booth oven sale units incorporate cutting-edge technology such as digital temperature monitoring, programmable heating cycles, and automated safety shutoffs. The dual-chamber design allows operators to spray paint in one section while simultaneously curing previously painted items in the heated compartment. These systems maintain optimal air pressure differentials to prevent dust and debris from contaminating freshly applied coatings. Applications span across automotive restoration, industrial equipment finishing, furniture manufacturing, and architectural metalwork. The spray booth oven sale market offers various configurations including crossdraft, downdraft, and semi-downdraft airflow patterns to accommodate different workspace requirements. Energy recovery systems capture and recycle heat from exhaust air, improving operational efficiency during extended use. Safety features include explosion-proof electrical components, emergency ventilation systems, and fire suppression capabilities. The integrated design eliminates the need for separate spray and cure facilities, maximizing floor space utilization while maintaining professional finishing standards. During promotional spray booth oven sale events, customers often receive additional benefits such as installation support, operator training, and extended warranty coverage.