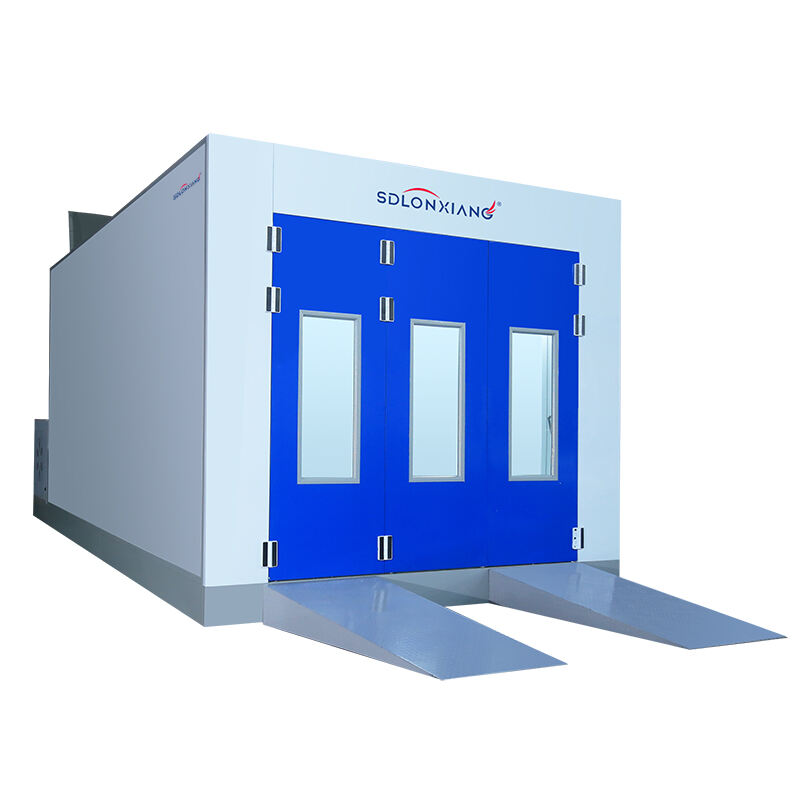

اسپرے بوتھ کے سازو سامان کی تیاری کنندہ

اسپرے بوتھس کے سازو سامان کی ایک کمپنی ایک مخصوص صنعتی کمپنی کی نمائندگی کرتی ہے جو اسپرے پینٹنگ اور کوٹنگ کے استعمال کے لیے خصوصی طور پر تیار کردہ بند وینٹی لیشن سسٹمز کو ڈیزائن، انجینئرنگ اور تیار کرتی ہے۔ ان کمپنیوں کا مرکزِ توجہ مختلف صنعتوں میں محفوظ، موثر اور معیاری مکمل کرنے کے عمل کو یقینی بنانے کے لیے جامع حل تیار کرنا ہوتا ہے۔ اسپرے بوتھ سسٹمز کا بنیادی کام اوور اسپرے کو روکنا، فضا میں موجود ذرات کو کنٹرول کرنا اور کوٹنگ آپریشنز کے دوران ماحولیاتی حالات کو بہترین سطح پر برقرار رکھنا ہوتا ہے۔ جدید اسپرے بوتھس کے سازو سامان کی سہولیات میں جدید فلٹریشن ٹیکنالوجی، درست ہوا کے بہاؤ کے انتظام کے نظام، اور بہترین کارکردگی کے معیارات فراہم کرنے کے لیے ترقی یافتہ کنٹرول کے طریقے شامل ہوتے ہیں۔ سرخیل اسپرے بوتھس کے سازو سامان والی کمپنیوں کے ذریعہ شامل کردہ ٹیکنالوجیکل خصوصیات میں متعدد مراحل پر مشتمل فلٹریشن سسٹمز، متغیر رفتار والے اخراج پنکھے، درجہ حرارت کنٹرول یونٹس، اور خودکار نگرانی کے نظام شامل ہیں جو ہوا کی کوالٹی اور بوتھ کی کارکردگی کے پیمانے کو نشاندہی کرتے ہیں۔ یہ سسٹمز پینٹ کے ذرات، کیمیائی بخارات اور دیگر آلودگی کو مؤثر طریقے سے پکڑتے ہیں اور پینٹرز کو صاف، اچھی طرح روشن کیے گئے کام کرنے کے ماحول کی فراہمی کرتے ہیں۔ اسپرے بوتھ سسٹمز کے استعمال کے شعبے میں خودکار چمکانے والی دکانیں، صنعتی تیاری کی سہولیات، ایروسپیس کمپنیاں، فرنیچر تیاری کی لائنز اور کسٹم تیاری کے ورکشاپس شامل ہیں۔ ہر اسپرے بوتھس کا سازو سامان عام طور پر مخصوص صنعتی ضروریات، ورک اسپیس کے ابعاد اور پیداواری حجم کے مطابق حسبِ ضرورت حل پیش کرتا ہے۔ انجینئرنگ کا عمل مقامی عمارت کے قوانین، ماحولیاتی اصولوں اور حفاظتی معیارات پر غور کرتا ہے تاکہ مطابقت اور بہترین کارکردگی کو یقینی بنایا جا سکے۔ جدید اسپرے بوتھس کے سازو سامان کے آپریشنز میں کمپیوٹر ایڈڈ ڈیزائن سافٹ ویئر کا استعمال کیا جاتا ہے تاکہ ایسی بوتھ کی تشکیلات تیار کی جا سکیں جو کارکردگی کو زیادہ سے زیادہ کریں اور توانائی کے استعمال کو کم سے کم کریں۔ بہت سی کمپنیاں جامع انسٹالیشن خدمات، جاری رکھنے کی حمایت اور آپریٹر تربیت کے پروگرام بھی فراہم کرتی ہیں تاکہ صارفین کو اپنی سرمایہ کاری سے زیادہ سے زیادہ منافع حاصل ہو۔ اسپرے بوتھ ٹیکنالوجی کی ترقی توانائی سے بچت والی موٹرز، اسمارٹ کنٹرول سسٹمز اور ماحولیاتی طور پر پائیدار فلٹریشن مواد میں نوآوریوں کے ذریعے جاری ہے جو آپریشنل اخراجات کو کم کرتے ہیں جبکہ بہترین کارکردگی کے معیارات برقرار رکھتے ہیں۔