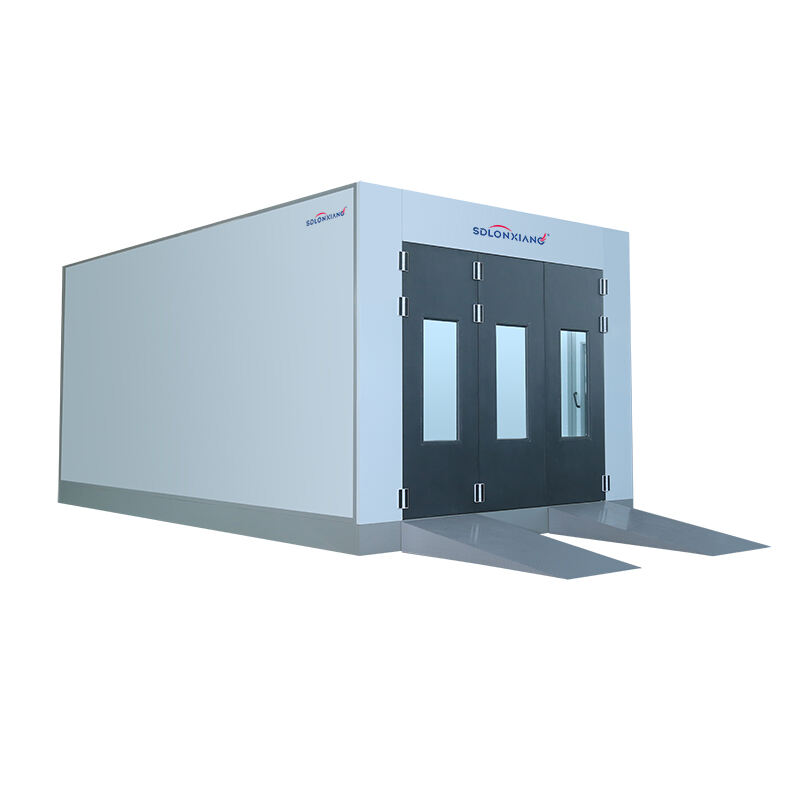

furnizues i kabinave për përdorim në automjete

Një furnizues i kabineve për përdredhje bojë automjetesh ofron pajisje dhe sisteme të specializuara të dizajnuara për të krijuar mjedise të kontrolluara për operacione përdredhjeje dhe riparimi të makinave. Këta furnizues prodhojnë dhe shpërndajnë zgjidhje të plota që përfshijnë kabinë të mbyllura për përdredhje, sisteme ventilimi, pajisje filtrimi, nxehtësi dhe instalime dritash, të inxhinierizuara veçanërisht për aplikime automobilistike. Funksioni kryesor i një furnizuesi kabine përdredhjeje boje automjetesh përkohet rreth ofrimit të mjediseve të plota përdredhjeje që sigurojnë aplikimin optimal të bojës, ruajtjen e standardeve të sigurisë dhe përputhshmërinë me kërkesat mjedisore. Furnizuesit modernë të kabinave për përdredhje boje automjetesh përfshijnë veçori teknologjike të avancuara si sisteme të automatizuara kontrolli klimatik, procese filtrimi me shumë faza, mekanizma të nxehtësisë me efikasitet energjetik dhe menaxhim të saktë të rrjedhës së ajrit. Këto sisteme ruajnë nivele të qëndrueshëm temperaturë dhe lagështie, ndërkohë që heqin grimcat e tepërta të përdredhjes dhe komponimet organike volatil nga mjedisi i punës. Aplikimet për pajisjet e furnizuesve të kabinave të përdredhjes së bojës automjetesh shtrihen në sektorë të ndryshëm, përfshirë fabrikat e prodhimit automobilistik, qendrat e riparimit pas aksidenteve, atelietë të makinave të personalizuara, operacionet e mirëmbajtjes së flotave dhe bizneset e rindërtimit të veçantë të mjeteve. Zgjidhjet profesionale të furnizuesve të kabinave të përdredhjes së bojës automjetesh zakonisht kanë modele rrjedhëje ajri me rrjedhë poshtë (downdraft) ose anësore (crossdraft) që drejtojnë ajrin e ndotur larg sipërfaqeve të përdredhura, duke parandaluar defekte dhe siguruar cilësi të lëmuar të përfundimit. Modelet e avancuara nga kompanitë kryesore furnizuese të kabinave të përdredhjes së bojës automjetesh përfshijnë kontroll të automatizuar, mundësi monitorimi nga distanca dhe sisteme të integruara tharjeje që përshpejtojnë proceset e tharjes së bojës. Zhvillimi teknologjik i pajisjeve të kohëve të sotme të furnizuesve të kabinave të përdredhjes së bojës automjetesh i lejon përdoruesve të arrijnë përfundime me cilësi fabrike, duke zvogëluar humbjet e materialeve dhe duke përmirësuar efikasitetin operativ. Këta furnizues ofrojnë gjithashtu shërbime të plota mbështetëse, përfshirë instalim, mirëmbajtje, trajnime dhe pjesë zëvendësuese për të siguruar performancë dhe besueshmëri të gjatëkohëshme të sistemeve për klientët e tyre në segmente të ndryshme të industrisë automobilistike.