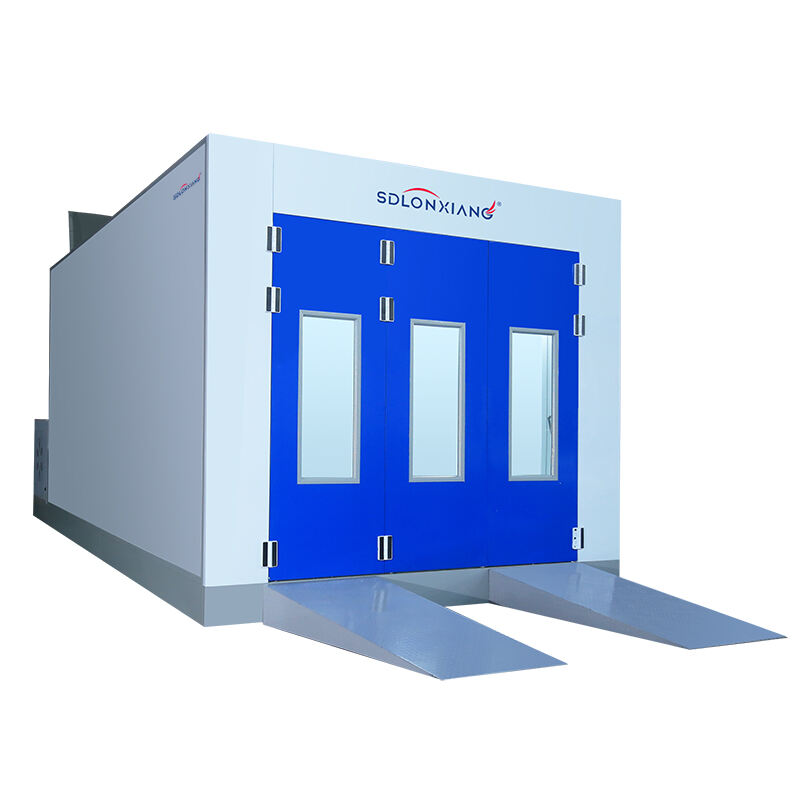

paint booth with heat

A paint booth with heat represents a sophisticated industrial solution designed to optimize the painting and finishing process across various manufacturing sectors. This advanced equipment combines controlled environmental conditions with integrated heating systems to ensure superior coating results and enhanced operational efficiency. The primary function of a paint booth with heat centers on creating an ideal microenvironment where temperature, airflow, and contamination control work harmoniously to deliver professional-grade finishes. The heating component serves multiple critical purposes, including accelerating paint curing times, improving paint flow characteristics, and maintaining consistent viscosity levels throughout the application process. Modern paint booth with heat systems incorporate state-of-the-art temperature control mechanisms that allow operators to precisely regulate thermal conditions based on specific coating requirements. These units typically feature advanced filtration systems that remove airborne particles and contaminants while maintaining optimal air circulation patterns. The technological framework of a paint booth with heat includes sophisticated control panels that enable real-time monitoring and adjustment of temperature, humidity, and airflow parameters. Safety features are extensively integrated, including explosion-proof components, emergency shutdown systems, and comprehensive ventilation controls. Applications span across automotive manufacturing, aerospace industries, furniture production, heavy machinery coating, and custom fabrication shops. The versatility of paint booth with heat systems makes them suitable for various coating materials, including water-based paints, solvent-based finishes, powder coatings, and specialty industrial coatings. Energy efficiency considerations have become paramount in modern designs, with many units featuring heat recovery systems that capture and recycle thermal energy, reducing operational costs while maintaining environmental compliance standards.