Верзибилни Мулти-Апликациски Капацитети

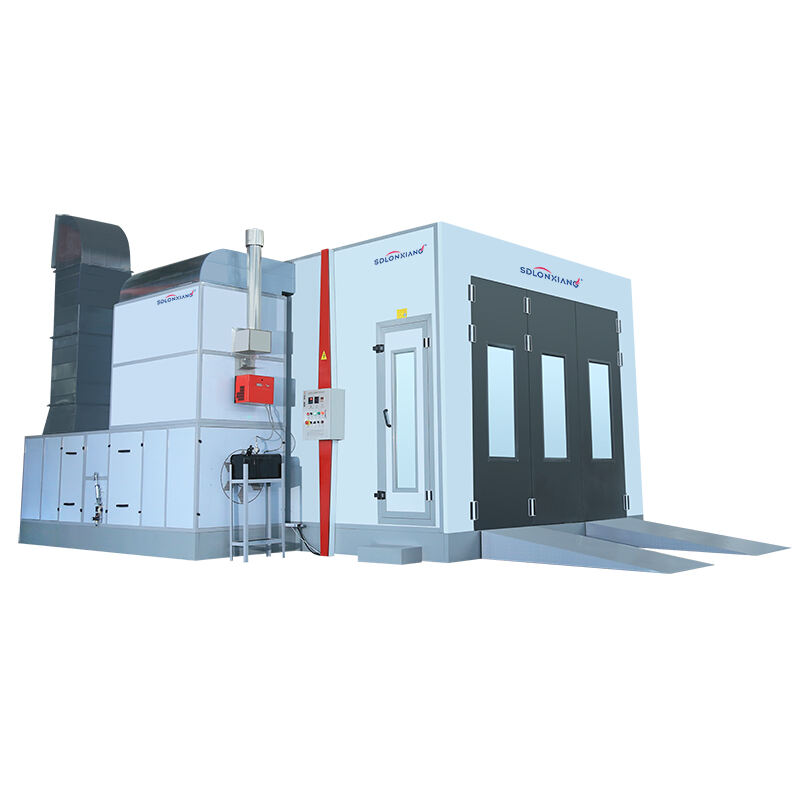

Изузетната свеобухватност на horno para pintar carros го прави незаменлив ресурс за разновидни применувања во автомобилското боење и пребоење, овозможувајќи се од целосно пребоење на возилата до специјализирани кастомизирани работи. Оваа прилагодливост потекнува од прилагодливи оперативни параметри што можат да се конфигурираат за различни системи на боја, големини на возила и барања за проекти. Пространата внатрешност овозможува различни типови на возила, од компактни автомобили до големи камиони, мотоцикли и комерцијални возила, максимално искористувајќи го опремувањето и вратувајќи го инвестираното. Horno para pintar carros се истакнува во применувањата за поправка по судири, каде што оштетените возила бараат прецизно совпаѓање на бојата и безпрекорно препокривање со постоечките боја. Контролираната средина им овозможува на мајсторите да постигнат невидливи поправки кои ги враќаат возилата во состојба пред судирот, исполнувајќи ги барањата на осигурувањето и очекувањата на клиентите. Кастомизираните автомобилски проекти многу им се заблагодаруваат на конзистентните услови обезбедени од horno para pintar carros, овозможувајќи на уметниците и стручњаците да креираат уникатни површини со сигурност во конечниот резултат. Операциите за одржување на возилски парки ги користат овие свеобухватни системи за одржување на конзистентни стандарди на изглед кај повеќе возила, осигурувајќи професионална презентација и заштита на бренд идентитетот. Опремата работи со разни технологии на боја, вклучувајќи водени системи, растворувачи и специјализирани прекривки како антикорозивни третмани и заштитни површини. Операциите за пребоење кај реставрација на класични автомобили бараат прецизен контрол што го обезбедува horno para pintar carros, осигурувајќи автентично повторување на бојата и трајност што ја заштитува вредноста на возилото. Системот ги покрива различните барања за исушилување на праймер, базичен слој и прозрачен слој, овозможувајќи целосни процеси на боење да се изведуваат во една иста установа. Специјализираните применувања како боење на мотоцикли, пребоење на ладии и работи на возила за рекреација имаат корист од контролираната средина и професионалните резултати што можат да се постигнат со horno para pintar carros. Системите се користат и во обуките за учење на правилните техники на боење во контролирани услови, развивајќи вешти техничари способни да одржуваат стандарди на квалитет. Оваа комплексна свеобухватност го прави horno para pintar carros основно средство за автомобилски бизниси кои сакаат да ја прошират својата понуда на услуги и да ги освојат разновидните пазарни прилики, при одржување конзистентни стандарди на квалитет.