Напредна технологија за контрола на животната средина

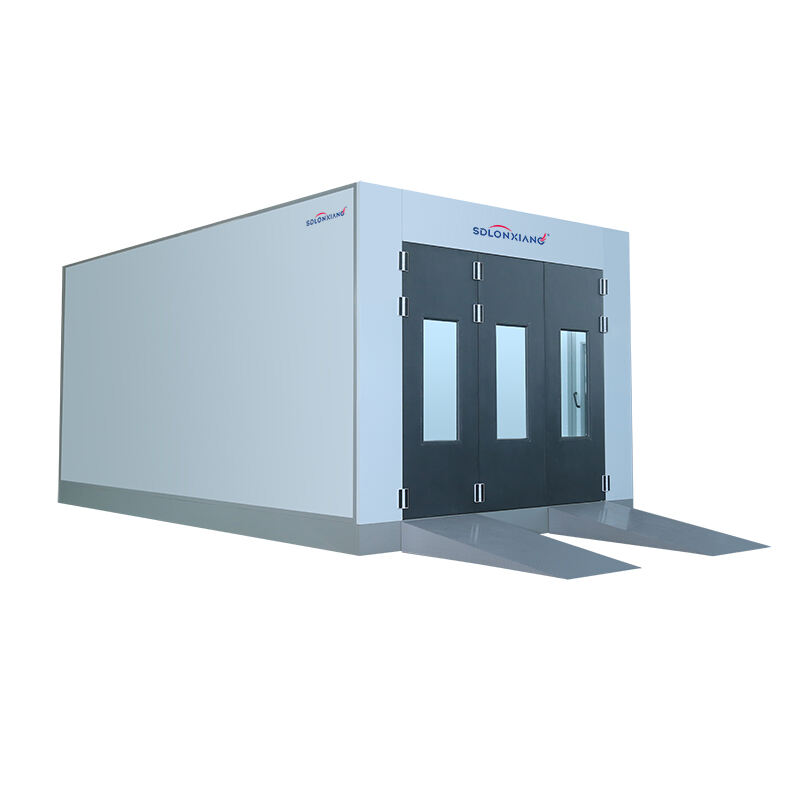

Софистицираната технологија за контрола на животната средина, развиена од водечки производител на кабини за бојадисување на автомобили, претставува револуционерен пристап кон автомобилското пребојадисување кој обичните работилници за поправка ги претвора во прецизни центри за бојадисување. Овој напреден систем создава прецизно контролирана атмосфера во која температурата, влажноста и параметрите на квалитетот на воздухот остануваат постојани во текот на целиот процес на бојадисување, осигувајќи оптимални услови за постигнување на завршни површини со квалитет на салон секој пат. Производителот на кабини за бојадисување на автомобили вградил мултизонални системи за контрола на климата кои автоматски ги прилагодуваат условите во зависност од специфичните барања за различните типови на прекривки и методи на нанесување. Технологијата вклучува интелигентни сензори кои непрекинато го следат квалитетот на воздухот, откривајќи и елиминирајќи загадувачи во воздухот пред да можат да го компромитираат прилепувањето на бојата или глаткоста на површината. Филтрацискиот систем, дизајниран од овој производител на кабини за бојадисување на автомобили, користи прогресивен тростепен процес кој отстранува честички мали колку 0,3 микрона, создавајќи ултрачиста средина која се споредува со фабричките центри за бојадисување. Автоматизираниот контролен интерфејс овозможува на операторите да изберат претходно програмирани поставки за различни типови на боја, вклучувајќи базни слоеви, заштитни слоеви и специјални завршни површини, при што системот автоматски ги прилагодува стапките на вентилација, поставките за температура и нивоата на влажност. Овој производител на кабини за бојадисување на автомобили интегрирал системи за рекуперација на енергија кои ја зграбуваат и повторно ја користат загреаната воздух, намалувајќи ги оперативните трошоци, а истовремено одржувајќи ги оптималните услови за бојадисување во текот на продолжени работни сесии. Мрежата за прецизно дистрибуирање на воздух обезбедува еднакви шеми на струење на воздухот, со што ги елиминира топлите точки, ладните зони и турбуленциите кои би можеле да предизвикаат дефекти на бојата или нееднакво покривање. Можностите за мониторинг на животната средина обезбедени од овој производител на кабини за бојадисување на автомобили вклучуваат логирање на податоци во реално време и системи за известување кои ја известуваат операторот за било какви одстапувања од оптималните услови, овозможувајќи моментални корективни мерки за спречување на проблеми со квалитетот на бојата.