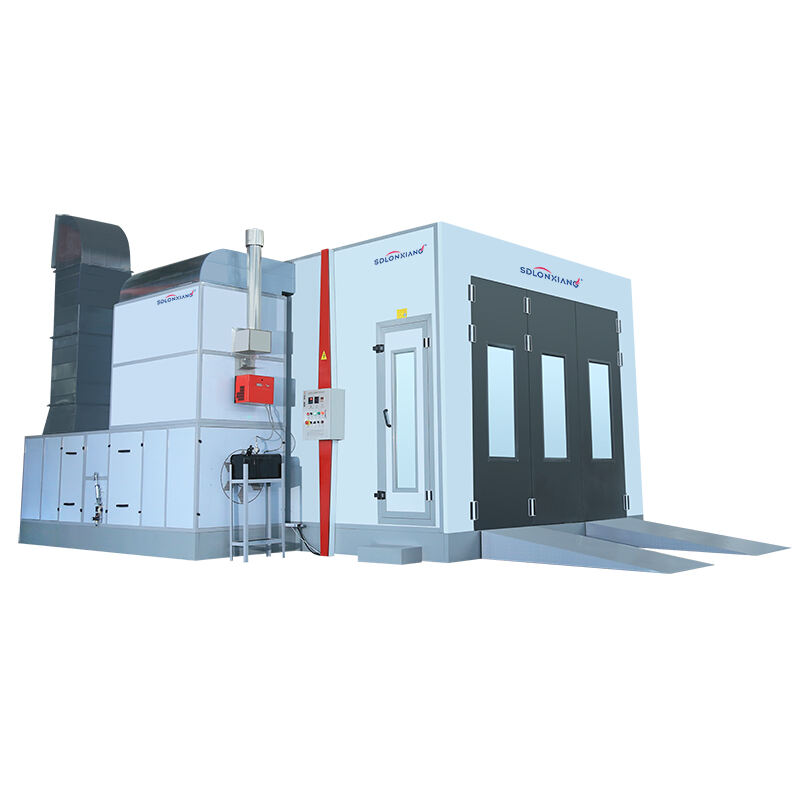

تامینکننده پانلهای کابینت رنگپاشی

تأمینکننده پنلهای کابین رنگ، شریکی حیاتی برای تولیدکنندگان خودرو، تأسیسات صنعتی و عملیات پوششدهی تخصصی است که به دنبال مواد ساختمانی باکیفیت بالا برای کابینهای اسپری هستند. این تأمینکنندگان متخصص، راهحلهای جامع پنل دیواری ارائه میدهند که برای ایجاد محیطهای کنترلشده در رنگآمیزی طراحی شدهاند و نتایج بهینه در اعمال پوشش را تضمین میکنند. شرکتهای تأمینکننده پنل کابین رنگ، سیستمهای ماژولار پنلی را ارائه میدهند که مطابق با استانداردهای دقیق صنعت در زمینه مدیریت جریان هوا، ایمنی در برابر آتشسوزی و کنترل آلودگی مهندسی شدهاند. عملکرد اصلی این پنلها، ایجاد محیطهای دربسته برای جلوگیری از پاشش بیش از حد رنگ همراه با حفظ الگوهای تهویه مناسب ضروری برای پرداختهای باکیفیت است. پنلهای مدرن کابین رنگ دارای نقاط یکپارچهسازی فیلتر پیشرفته هستند که اتصال بدون درز به سیستمهای تخلیه و تأمین هوای تازه را فراهم میکنند. پیشرفت فناوری در طراحی پنلهای معاصر شامل سیستمهای درزگیر تخصصی است که از نشت هوا جلوگیری میکنند و اختلاف فشار یکنواخت در داخل کابین را تضمین میکنند. بسیاری از سازمانهای تأمینکننده پنل کابین رنگ، پیکربندیهای قابل تنظیم پنل را برای سازگاری با ابعاد مختلف کابین و نیازهای عملیاتی ارائه میدهند. این پنلها معمولاً دارای هستههای غیرقابل اشتعال هستند که با روکشهای فولادی احاطه شدهاند و در برابر تماس با مواد شیمیایی حلالها و عوامل پاککننده که معمولاً در فرآیندهای رنگآمیزی استفاده میشوند، مقاومت میکنند. پوششهای سطحی اعمالشده بر روی این پنلها، سطوحی صاف و قابل تمیزشدن ایجاد میکنند که انباشت ذرات را به حداقل میرسانند و رویههای نگهداری را ساده میسازند. کارایی نصب جنبه دیگری مهم در خدمات حرفهای تأمینکنندگان پنل کابین رنگ است، که بسیاری از شرکتها سیستمهای پیشمهندسیشده را ارائه میدهند تا زمان مونتاژ در محل را کاهش دهند. این پنلها اغلب دارای مکانیزمهای قفلی هستند که اتصالات ساختاری محکمی ایجاد میکنند، در حالی که یکپارچگی محیطی لازم برای عملیات پوشش حرفهای را حفظ میکنند. شرکتهای باکیفیت تأمینکننده پنل کابین رنگ همچنین خدمات پشتیبانی فنی ارائه میدهند و به مشتریان کمک میکنند تا مشخصات مناسب پنل را بر اساس الزامات کاربردی خاص، حجم تولید و نیازهای انطباق با مقررات انتخاب کنند.