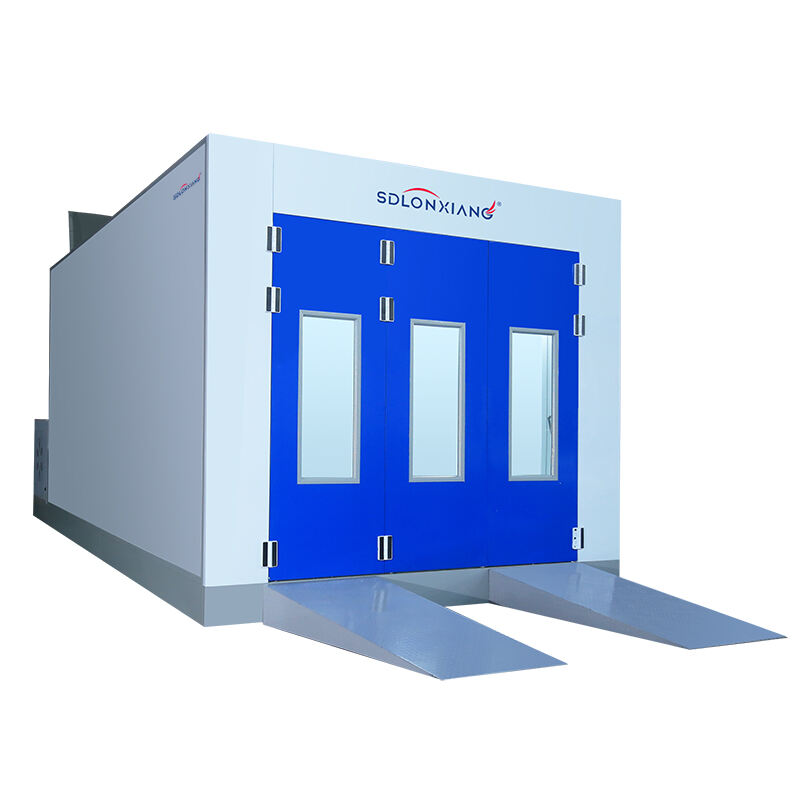

vehicle paint booth

A vehicle paint booth represents a specialized enclosed workspace designed specifically for automotive painting operations, providing controlled environmental conditions that ensure professional-quality finishes on cars, trucks, motorcycles, and other vehicles. These sophisticated systems create an isolated chamber where temperature, humidity, airflow, and contamination levels are precisely regulated to achieve optimal paint application results. The primary function of a vehicle paint booth centers on maintaining a clean, dust-free environment while facilitating proper paint curing through controlled heating and ventilation systems. Modern vehicle paint booth installations incorporate advanced filtration technology that removes airborne particles, preventing defects like orange peel texture, runs, or contamination spots that can ruin expensive paint jobs. The booth operates through a systematic airflow pattern, typically drawing fresh air through ceiling-mounted intake filters while exhausting contaminated air through floor-level extraction points, creating a downward airflow that carries overspray and particles away from the vehicle surface. Temperature control systems within the vehicle paint booth allow operators to maintain consistent heat levels during both application and curing phases, which is critical for proper paint adhesion and durability. Most commercial-grade units feature programmable controls that automatically adjust environmental parameters based on the specific paint system being used, whether it involves basecoat-clearcoat processes, single-stage applications, or specialty coatings. The enclosed design of a vehicle paint booth also serves important safety functions by containing volatile organic compounds and preventing exposure to hazardous fumes, while integrated fire suppression systems provide additional protection against ignition risks. These facilities find widespread application across automotive repair shops, body shops, manufacturing plants, custom car builders, fleet maintenance operations, and industrial coating facilities where consistent, high-quality results are essential for customer satisfaction and business reputation.