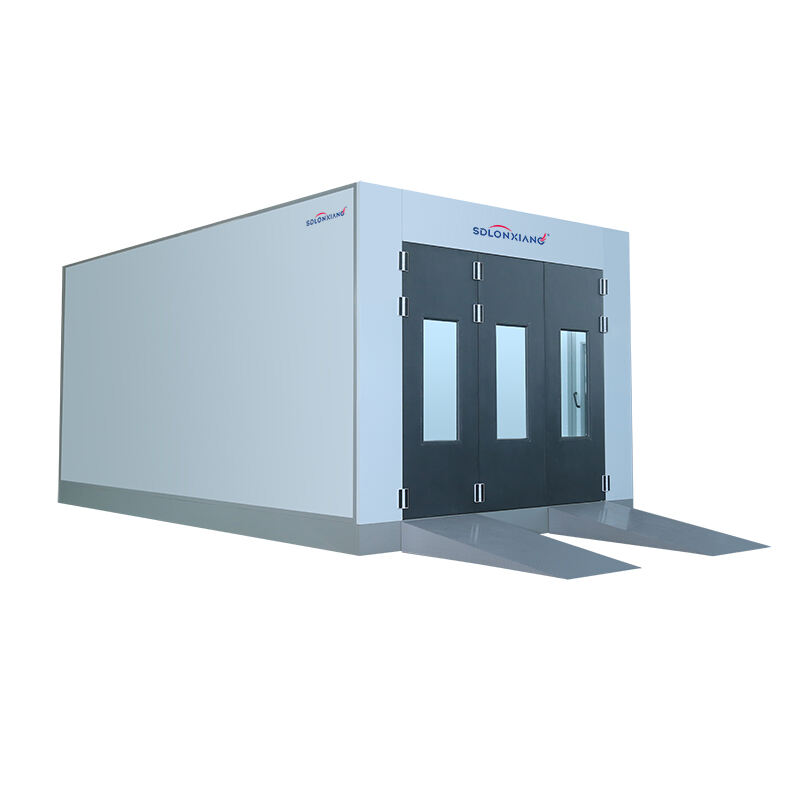

paint booth for cabinets

A paint booth for cabinets represents a specialized industrial finishing system designed specifically for coating cabinet components and furniture pieces with precision and consistency. This controlled environment chamber creates optimal conditions for applying various types of finishes, including lacquers, stains, primers, and topcoats to wooden, metal, or composite cabinet materials. The paint booth for cabinets operates through sophisticated ventilation systems that maintain proper airflow patterns, ensuring even paint distribution while capturing overspray particles and volatile organic compounds. Modern cabinet paint booths incorporate advanced filtration technology, temperature control mechanisms, and lighting systems that enable operators to achieve professional-grade finishes consistently. These systems typically feature intake filters that clean incoming air, exhaust filters that capture paint particles, and circulation fans that maintain steady airflow throughout the coating process. The controlled atmosphere within a paint booth for cabinets eliminates dust contamination, reduces humidity fluctuations, and provides consistent temperature conditions that are crucial for proper paint adhesion and curing. Many contemporary models include automated conveyor systems that transport cabinet doors, frames, and panels through designated coating zones at predetermined speeds. The booth's design incorporates safety features such as explosion-proof electrical components, fire suppression systems, and emergency ventilation controls to protect operators and equipment. Advanced paint booth systems for cabinets often integrate with computerized control panels that monitor environmental conditions, track production metrics, and provide diagnostic information for maintenance scheduling. The workspace configuration typically includes operator platforms, gun hangers, material preparation areas, and storage compartments for coating supplies. These sophisticated finishing systems accommodate various cabinet sizes and configurations while maintaining optimal spray patterns and finish quality throughout extended production runs.