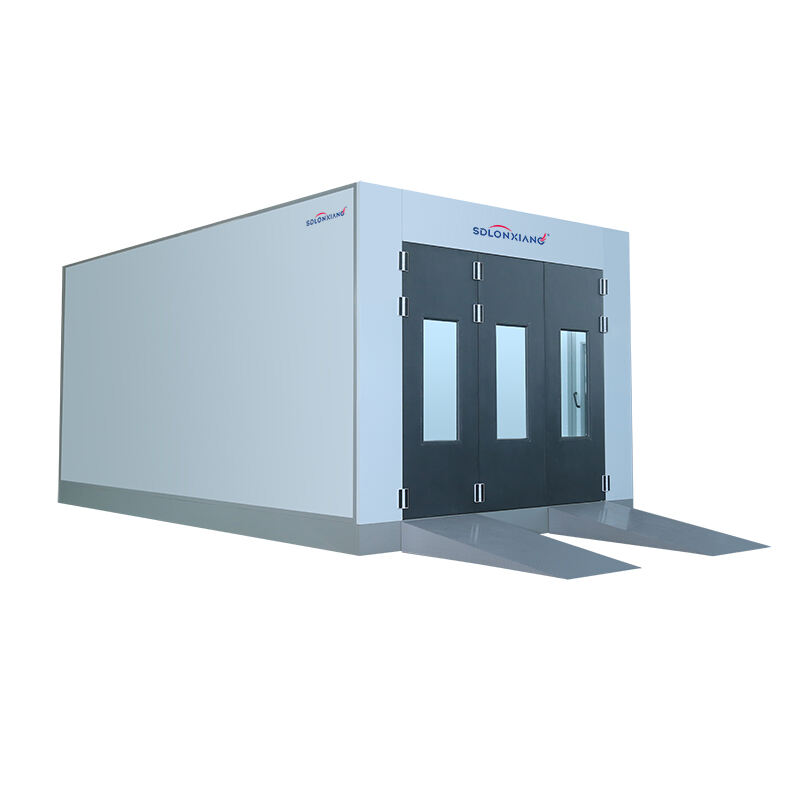

horno para pintura automotriz

The horno para pintura automotriz represents a revolutionary advancement in automotive paint curing technology, specifically engineered to deliver exceptional results in professional automotive refinishing operations. This specialized automotive paint oven combines precision heating systems with advanced airflow management to create optimal curing environments for various paint formulations. The horno para pintura automotriz utilizes sophisticated temperature control mechanisms that maintain consistent heat distribution throughout the curing chamber, ensuring uniform paint adhesion and finish quality across entire vehicle surfaces. Modern automotive paint ovens incorporate energy-efficient heating elements, programmable control systems, and safety features that meet stringent industry standards. The primary function of the horno para pintura automotriz centers on accelerating paint curing processes while maintaining color integrity and preventing defects such as orange peel, runs, or uneven gloss levels. These systems feature stainless steel construction for durability and easy maintenance, while specialized filtration systems capture overspray and maintain air quality standards. The technological framework of the horno para pintura automotriz includes digital temperature monitoring, automated cycle programming, and real-time performance tracking capabilities. Applications span from collision repair centers and automotive manufacturing facilities to custom paint shops and restoration workshops. The horno para pintura automotriz accommodates various paint types including basecoats, clearcoats, primers, and specialty finishes, making it versatile for different automotive painting requirements. Advanced models feature zone-specific heating controls, allowing operators to customize temperature profiles for different vehicle sections or paint systems. The integration of modern technology in the horno para pintura automotriz enables consistent results, reduced labor costs, and improved throughput in automotive painting operations, establishing it as an essential component in professional automotive refinishing environments.