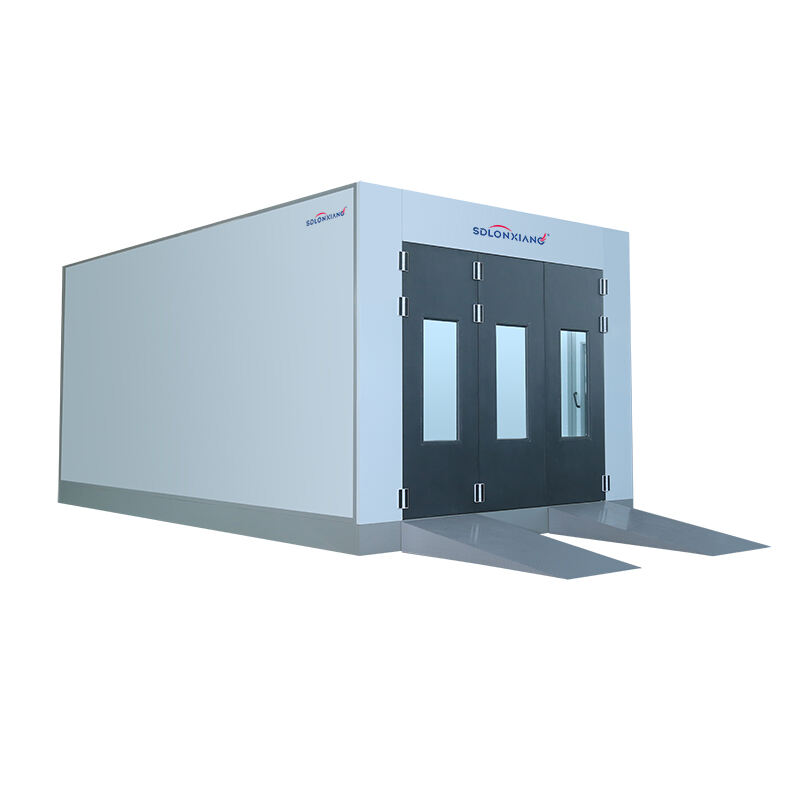

proizvođač kabina za farbanje automobila

Кабина за бојење аутомобила за произвођаче представља софистицирану индустријску постројбу која је специјално дизајнирана за прецизно и конзистентно наношење заштитних и декоративних премаза на аутомобиле. Ове специјализоване коморе стварају контролисане услове који обезбеђују оптималне услове за наношење боје, уз истовремено одржавање стандарда безбедности и прописа о заштити животне средине. Кабина за бојење аутомобила за произвођаче чини темељну основу операција завршне обраде возила, где се сирови кућишта претварају у полирана, тржишту спремна возила кроз напредне процесе премазивања. Савремени системи кабина за бојење интегришу најновију технологију, укључујући рачунарски контролисано климатско управљање, напредне системе филтрације и аутоматизоване системе прскања који обезбеђују једнолико покривање чак и на сложеним геометријама возила. Основна функција кабине за бојење аутомобила превазилази једноставно наношење боје и обухвата комплексну припрему површина, наношење прајмера, прскање базног слоја и завршну обраду прозирним премазом. Ове постројбе одржавају прецизне нивое температуре и влажности, обично у опсегу од 65–75 степени Фаренхајта са контролисаном влажношћу између 40–60 посто, чиме се осигуравају оптимални услови за ток и прилијање боје. Напредни системи вентилације у кабини за бојење аутомобила стварају ламинарне шеме протока ваздуха који елиминишу загађиваче, истовремено обезбеђујући безбедне радне услове за раднике. Технолошка инфраструктура обухвата софистициране системе гашења пожара, експлозијом сигурне електричне компоненте и могућности мониторинга у реалном времену који прате параметре средине током целокупног процеса премазивања. Индустријски системи кабина за бојење подносе разне величине возила, од компактних аутомобила до великих теренских и комерцијалних возила, са прилагодљивим системима транспортера и флексибилним конфигурацијама кабина. Кабина за бојење аутомобила укључује енергетски ефикасне системе грејања, који често користе природни гас или електричне грејаче са механизми за рекуперацију топлоте, како би се смањили оперативни трошкови, а истовремено одржали конзистентни профили температуре неопходни за премазе високог квалитета.