nxehtës të kabines së ngjyrosjes

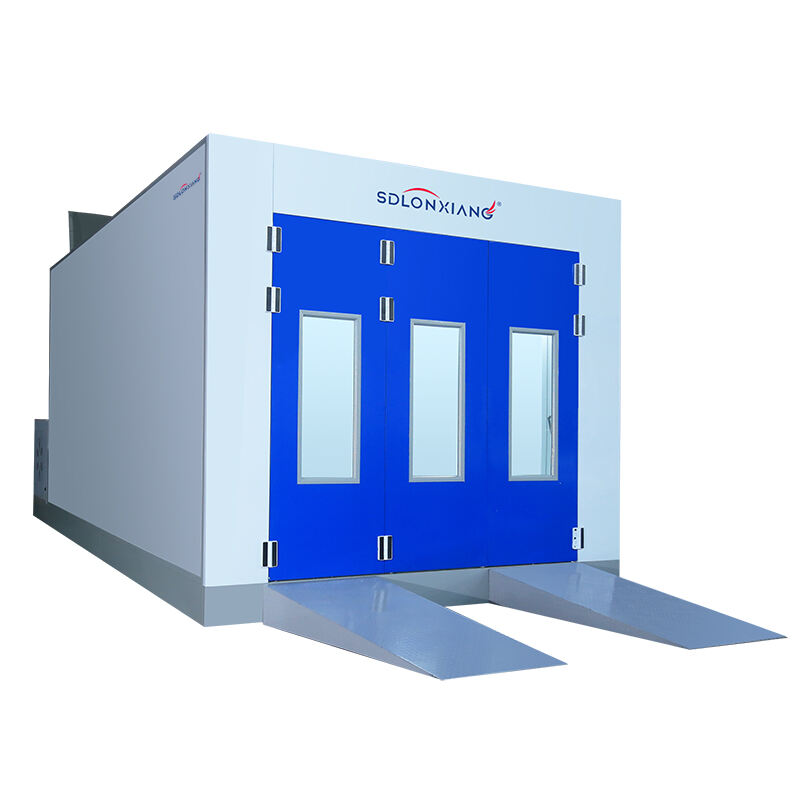

Ngrohësit e kabinit të pikturimit përfaqësojnë pajisje të thelbësishme për instalimet profesionale të ripikturimit automotiv, operacionet industriale të përfshirjes dhe mjediset e prodhimit ku kushtet e kontrolluara të temperaturës janë kritike për aplikimin optimal të pikturës dhe proceset e tharjes. Këto sisteme të specializuara ngrohëse janë projektuar për të ruajtur temperatura të qëndrueshme brenda kabineve të spricit, duke siguruar ngjitje të duhur të pikturës, zvogëlimin e defekteve dhe përshpejtimin e kohës së tharjes. Ngrohësit e kabinit të pikturimit përdorin teknologji të avancuar djegjeje, të cilat zakonisht djegin gaz natyral, propan ose naftë për të prodhuar ajër të nxehtë të pastër dhe të filtruar që qarkullon në tërë mjedisin e kabinit. Funksionet kryesore të ngrohësve të kabinit të pikturimit përfshijnë rregullimin e temperaturës, kontrollin e lagështisë dhe menaxhimin e qarkullimit të ajrit, duke krijuar kushte ideale për aplikime të ndryshme të përfshirjes. Ngrohësit modernë të kabinit të pikturimit kanë sisteme të sofistikuara kontrolli që i lejojnë operatorëve të rregullojnë me saktësi cilësimet e temperaturës, të monitorojnë konsumin e karburantit dhe të ruajnë modele optimale rrjedhjeje ajri. Këto njësi përfshijnë mekanizma sigurie si sensorë flame, çelësa presioni dhe sisteme ndalimi emergjencë për të parandaluar aksidentet dhe për të siguruar funksionim të besueshëm. Karakteristikat teknologjike të ngrohësve të kohëve të sotëm të kabinit të pikturimit përfshijnë shkëmbyes të nxehtësisë me efikasitet të lartë që maksimalizojnë përdorimin e karburantit ndërkohë që minimizojnë emetimet. Sistemet e avancuara të filtrimit heqin ndotësit nga ajri i djegies, duke parandaluar ndotjen e sipërfaqeve të pikturuara. Panelët dixhitalë kontrolli ofrojnë monitorim në kohë reale të performancës së sistemit, duke i lejuar operatorëve të bëjnë rregullime menjëhershe bazuar në kërkesat specifike të përfshirjes. Aplikimet për ngrohësit e kabinit të pikturimit shtrihen nëpër shumë industri, përfshirë ofiat e riparimit automotiv, instalimet e mirëmbajtjes ajrore, prodhimin e mobilieve, ripikturimin e pajisjeve të rënda dhe operacionet e përfshirjes arkitektonike. Këto sisteme përshtaten me madhësi dhe konfigurime të ndryshme kabinesh, nga kabinet e vogla automotiv të spricit deri te sistemet industriale të mëdha të përfundimit. Ngrohësit e kabinit të pikturimit rrisin produktivitetin duke zvogëluar kohët e tharjes, duke përmirësuar cilësinë e përfundimit dhe duke mundësuar funksionim gjatë gjithë vitit pavarësisht nga kushtet e temperaturës ambiente, duke i bërë kështu ata mjete të padishme për aplikime profesionale të përfshirjes.