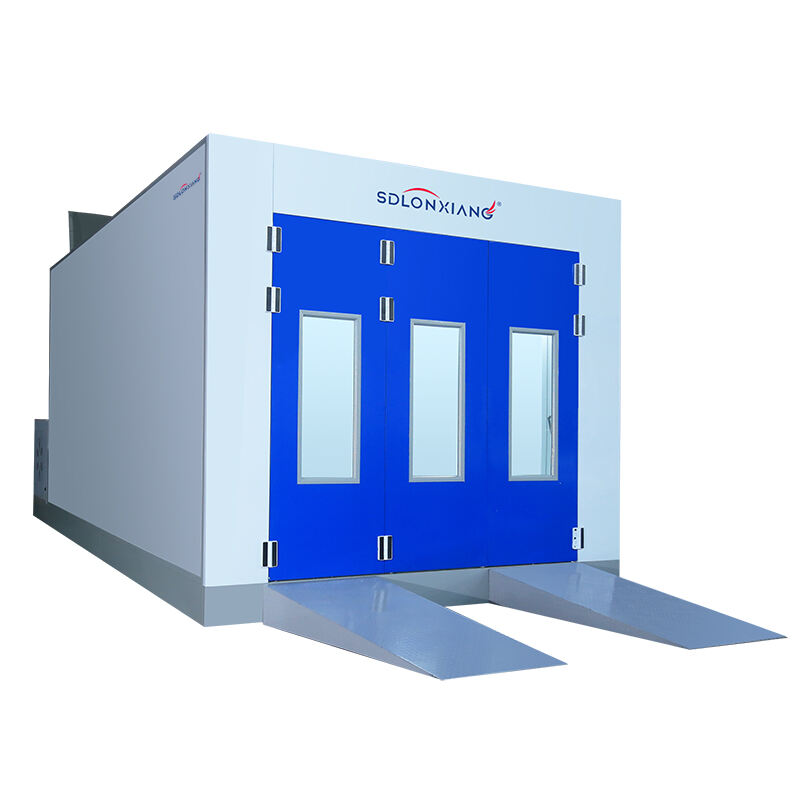

Sisteme të Gjërë të Sigurisë dhe Mbrojtjes së Mjedisit

Kabinitë automatike për përdorim të pulverizatorit integrojnë sisteme të plotë sigurie dhe mbrojtjeje nga e ndotja që vendosin standarde kryesuese në industri për mbrojtjen e punonjësve dhe zbatimin e rregullores në veprimet e pikturimit të automjeteve. Kuadri i sigurisë përfshin shumë shtresa mbrojtjeje, përfshirë sisteme elektrike rezistente ndaj eksplosionit, teknologji për suprimimin e zjarrit, kontrolla ventilimi emergjent dhe kapje të avujve të rrezikshëm, të dizajnuara për të eliminuar rreziqet e lidhura me proceset e aplikimit të pikturës. Instalimet drite dhe pjesët elektrike rezistente ndaj eksplosionit i plotësojnë kodet strikte të sigurisë për mjediset e rrezikshme ku janë të pranishme avujt dhe grimcat e djegshme. Sistemet elektrike përdorin kabinete specializuar, tubacione dhe mekanizma çelësi që parandalojnë burimet e djegies, duke ruajtur njëkohësisht dritë të mjaftueshme për aplikimin e cilësor të pikturës. Sistemet e suprimimit të zjarrit përfshijnë sensorë detektimi automatik, agjentë për suprimim dhe protokolle reagimi emergjent që aktivizohen menjëherë kur zbulohen kushte zjarri. Sistemet e ventilimit emergjent ofrojnë mundësi shkëmbimi të shpejtë ajri që pastron shpejt atmosferat e rrezikshme dhe siguron kushte të sigurta evakuimi për operatoret. Kuadri i mbrojtjes nga e ndotja përfshin sisteme filtrimi sofistikuar që kapin grimcat e pikturës, komponimet organike volatil dhe emetime të tjera para daljes së ajrit në atmosferë. Teknologjia e filtrimit me shumë stade heq grimca të madhësive të ndryshme, ndërsa sistemet me karbon aktiv absorb lëndë kimike avulluese dhe erërat. Dizajni i kapjes parandalon përdredhjen e tepërt nga zona e kabinit, duke mbrojtur pajisjet dhe hapësirat e punës rrethuese nga ndotja. Sistemet automatike monitorimi gjurmëzohen vazhdimisht cilësinë e ajrit, diferencat e presionit dhe nivelet e emitimeve për të siguruar zbatimin e rregullores mjedisore. Sistemet e sigurisë përfshijnë kërkesa për pajisje personale mbrojtëse, protokolle trajnimi dhe procedura emergjente që mbrojnë punonjësit nga ekspozimi ndaj materialeve të rrezikshme. Ndërprerësit e ventilimit parandalojnë funksionimin e kabinit kur kushtet e sigurisë nuk janë të plotësuara, duke siguruar që operatorët të mos krijojnë situata të rrezikshme pa dashur. Sistemet e mbrojtjes mjedisore i lejojnë bizneseve të funksionojnë në përputhje me rregulloret lokale, shtetërore dhe federale, duke treguar përgjegjësi korporative. Rëndësia e këtyre sistemeve të plota mbrojtëse shtrihet edhe te zbatimi ligjor, kërkesat e sigurimeve, siguria e punonjësve dhe marrëdhëniet me komunitetin. Bizneset përfitojnë nga eksponimi i reduktuar i përgjegjësisë, premia më e ulët e sigurimeve dhe përmirësimi i ruajtjes së punonjësve përmes kushteve të përmirësuara të sigurisë. Vlera e propozimit përfshin garantimin e përputhshmërisë me rregulloret, reduktimin e ndikimit mjesor, përmirësimin e kulturës së sigurisë në vendin e punës dhe reputacionin e theksuar të biznesit që tërheq punonjës të kualifikuar dhe konsumatorë të vetëdijshëm mjesor.