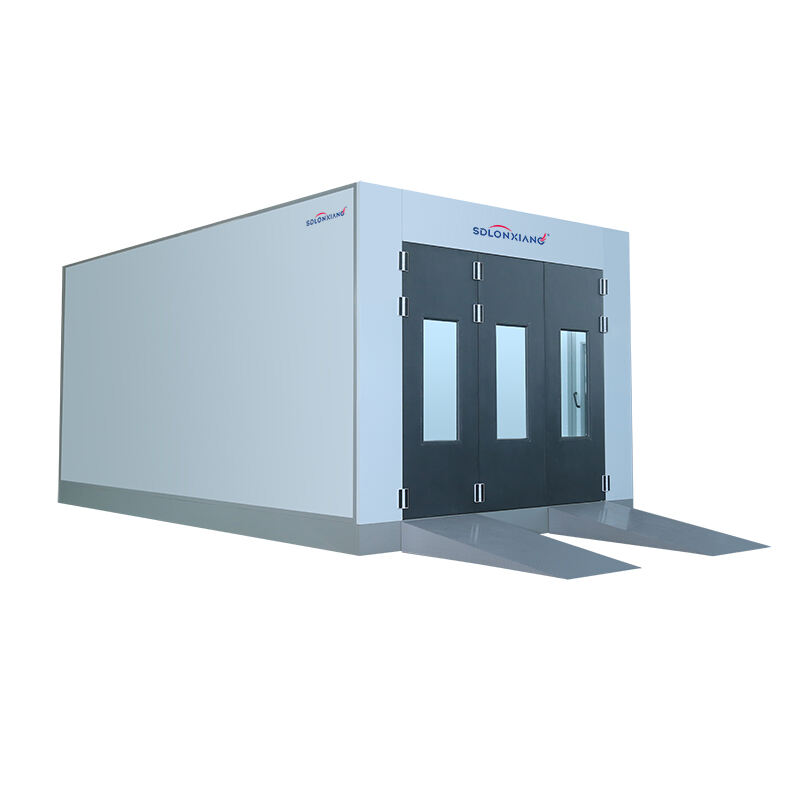

barvilna kabina za omarice

Barvni kabin za omarice predstavlja specializiran industrijski sistem za dokončno obdelavo, ki je namenjen posebej premazu komponent omaric in pohištva z natančnostjo in doslednostjo. Ta nadzorovana okoljska komora ustvarja optimalne pogoje za nanašanje različnih vrst premazov, vključno z lakovi, barvilnimi sredstvi, podlagami in zaščitnimi premazi na lesene, kovinske ali kompozitne materiale omaric. Barvni kabin za omarice deluje prek sofisticiranih prezračevalnih sistemov, ki ohranjajo ustrezne vzorce pretoka zraka, s čimer zagotavljajo enakomerno porazdelitev barve, hkrati pa zadržujejo delce presežne razpršene barve in hlapne organske spojine. Sodobni kabini za barvanje omaric vključujejo napredne tehnologije filtracije, mehanizme za nadzor temperature in osvetlitvene sisteme, ki omogočajo uporabnikom dosledno doseganje profesionalne kakovosti premaza. Ti sistemi imajo običajno filtre za dovajanje zraka, ki očistijo vhodni zrak, izpušne filtre, ki zadržijo delce barve, in ventilatorje za cirkulacijo, ki ohranjajo enakomeren pretok zraka skozi celoten proces premazovanja. Nadzorovano okolje znotraj barvnega kabina za omarice odpravi onesnaženje s prahom, zmanjša nihanja vlažnosti in zagotavlja stalne temperaturne pogoje, ki so ključni za pravilno oprijemanje in utrjevanje barve. Mnogi sodobni modeli vključujejo avtomatizirane transportne sisteme, ki prevažajo vrata omaric, okvirje in plošče skozi določena območja za premazovanje s predhodno določeno hitrostjo. Konstrukcija kabina vključuje varnostne elemente, kot so električni deli, odporni proti eksploziji, sistemi za gašenje požara ter nadzorne enote za izredno prezračevanje, za zaščito uporabnikov in opreme. Napredni sistemi barvnih kabin za omarice pogosto integrirajo računalniško nadzorovane nadzorne plošče, ki spremljajo okoljske pogoje, beležijo proizvodne metrike in zagotavljajo diagnostične podatke za načrtovanje vzdrževanja. Konfiguracija delovnega prostora običajno vključuje delovne platforme za uporabnike, nosilce za pištole, območja za pripravo materialov in shranjevalne predelke za zaloge premazov. Ti sofisticirani sistemi za dokončno obdelavo omogočajo različne velikosti in konfiguracije omaric, hkrati pa ohranjajo optimalne vzorce razprševanja in kakovost premaza tudi pri daljših serijah proizvodnje.