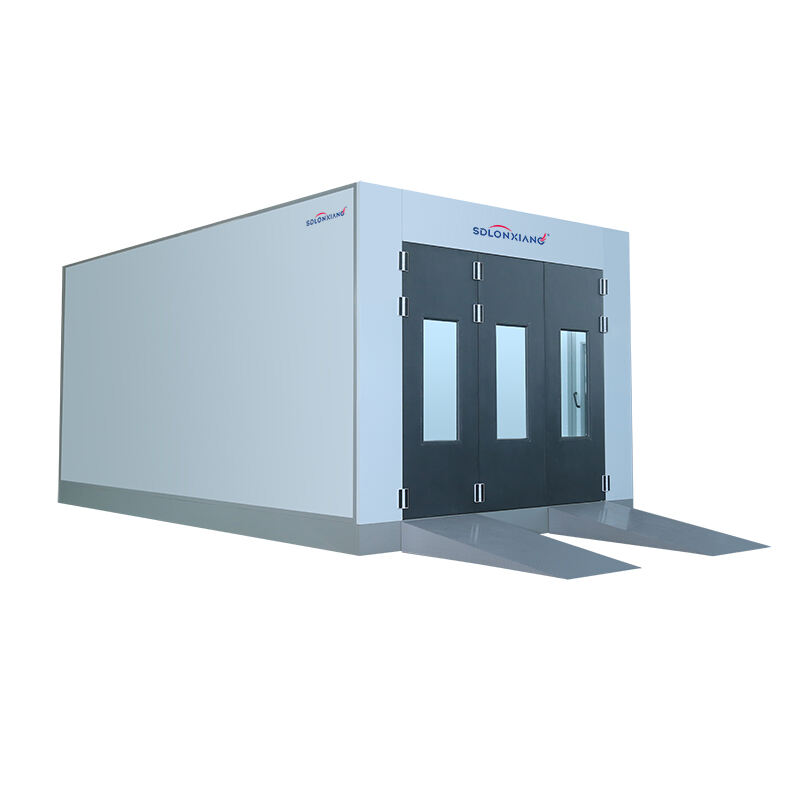

будаг хийх кабин, цахилгаан хиймэл нүүрс худалдах

Салхины шүүлт, будаглах орчин болон хатаах системийг шинэчлэхийг хүсч буй автомашин засварын газрууд, үйлдвэрлэлийн нөхцлүүд болон тусгай будаглах үйл ажиллагааны төвүүдэд будаглах кабин цэвэршүүрийн зар сурталчилгаа нь томоох сайн боломжийг олгоно. Эдгээр дэвшилтэт төхөөрөмжүүд нь будаглах кабин болон дотор нь суурилуулсан хатаах зуухны үйл ажиллагааг нэгтгэсэн байдаг тул мэргэжлийн түвшний будаглах ажилд комплекс шийдэл болдог. Будаглах кабин цэвэршүүрийн зар сурталчилгааны үеэр хэрэглэгчид авгалз шүүлтийн систем, нарийвчлалтай температурын хяналт, энергийг хэмнэх халаалтын механизм зэрэг дэвшилтэт технологитой өндөр чанартай төхөөрөмжийг өрсөлдөхүйц үнээр авах боломжтой. Ийм системийн үндсэн үйл функцийн дотор удирдлагатай орчинд будаглах, шүүлтийн агаарын эргэлтээр бохирдлыг зайлуулах, үйлдвэрлэлийн цагийг багасгах хурдасгуур хатаах процессыг хамааруулна. Орчин үеийн будаглах кабин цэвэршүүрийн зар сурталчилгааны загваруудад тоон температурын хяналт, програмчлаж болох халаалтын цикл, автоматаар аюулгүй байдлыг хангах зэрэг шинэ технологиудыг агуулсан байдаг. Хоёр камер бүхий загвар нь нэг хэсэгт будаглах үйлдлийг хийж байхдаа өмнө нь будсан зүйлсийг халаасан хэсэгт зэрэг хатаах боломжийг олгодог. Эдгээр систем нь шинээр будсан давхрагыг тоос болон бохирдолд өртөхөөс сэргийлэхийн тулд агаарын даралтын зөрүүг оновчтой түвшинд байлгадаг. Хэрэглээ нь автомашин сэргээх, ийлдвэрийн тоног төхөөрөмжийн гадна талыг будах, мебель үйлдвэрлэх, барилгын металл бүтээцэд хүртэл өргөн хүрээг хамардаг. Будаглах кабин цэвэршүүрийн зар сурталчилгааны зах зээл нь ажлын талбайн шаардлагад нийцүүлэн хөндлөн урсгал, доошоо чиглэсэн урсгал, хагас доошоо чиглэсэн урсгал зэрэг агаарын урсгалын янз бүрийн хувилбарыг санал болгодог. Энергийн сэргээлтийн систем нь гарсан агаараас дулааныг барьж, дахин ашиглах замаар урт хугацааны ашиглалтын үеийн үйл ажиллагааны үр ашгийг сайжруулдаг. Аюулгүй байдлын онцлог шинж чанаруудад эвлэрэх эрсдэлтэй цахилгаан хэрэгслүүд, яаралтай тусламжийн вентиляци, галыг унтраах боломжийг хамааруулна. Нэгтгэсэн загвар нь тусдаа будаглах болон хатаах төвийг шаардах шаардлагыг арилгаж, шалны зайг илүү үр дүнтэй ашиглах боломжийг олгох бөгөөд мэргэжлийн түвшний будаглах стандартыг хадгалж байдаг. Тусгай сурталчилгааны үеэр хэрэглэгчдэд ихэвчлэн суурилуулах дэмжлэг, ажиллаж сурах сургалт, баталгаат хугацааг уртасгах зэрэг нэмэлт давуу талуудыг санал болгодог.