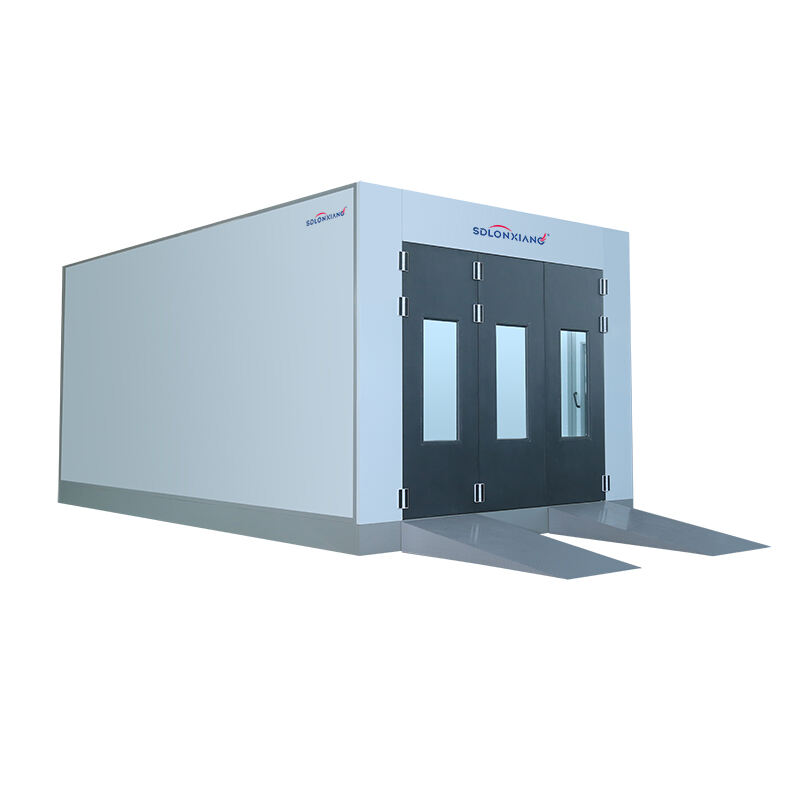

자동차용 도장 부스 제조업체

자동차 제조업체용 페인트 부스는 자동차에 보호 및 장식 코팅을 정밀하고 일관되게 도포하기 위해 특별히 설계된 정교한 산업 시설이다. 이러한 전문 시설은 페인트 도포에 최적의 조건을 보장하면서도 안전 기준과 환경 규정을 준수하는 통제된 환경을 조성한다. 자동차 제조업체용 페인트 부스는 정제되지 않은 차체가 고급스럽고 시장 출시 가능한 완성차로 변모하는 자동차 마감 공정의 핵심 역할을 한다. 최신 페인트 부스 시스템은 컴퓨터화된 기후 제어, 고성능 필터링 장치, 복잡한 차량 형상을 따라 균일한 도포를 제공하는 자동 스프레이 시스템 등 첨단 기술을 통합하고 있다. 자동차 제조업체용 페인트 부스의 주요 기능은 단순한 페인트 도포를 넘어서, 표면 전처리, 프라이머 도포, 베이스 코트 분사 및 클리어 코트 마감 공정까지 포괄한다. 이러한 시설은 일반적으로 섭씨 18~24도, 습도 40~60%를 유지하여 페인트의 흐름성과 부착력을 최적화한다. 자동차 제조업체용 페인트 부스 내부의 고도화된 환기 시스템은 층류 공기 흐름을 형성하여 오염물질을 제거하면서 동시에 작업자에게 안전한 작업 환경을 제공한다. 기술 인프라에는 정교한 소화 시스템, 폭발 방지 전기 부품, 코팅 공정 전반에 걸쳐 환경 변수를 실시간으로 모니터링하는 기능이 포함된다. 산업용 페인트 부스 시스템은 소형차부터 대형 SUV 및 상용차에 이르기까지 다양한 차량 크기를 수용하며, 조절 가능한 컨베이어 시스템과 유연한 부스 구성을 특징으로 한다. 자동차 제조업체용 페인트 부스는 에너지 효율적인 난방 시스템을 채택하여 운영 비용을 최소화하면서도 고품질 마감에 필수적인 일관된 온도 프로파일을 유지한다. 이 시스템은 종종 천연가스 또는 전기 히터를 사용하며, 열 회수 장치를 통합하여 에너지 효율을 극대화한다.