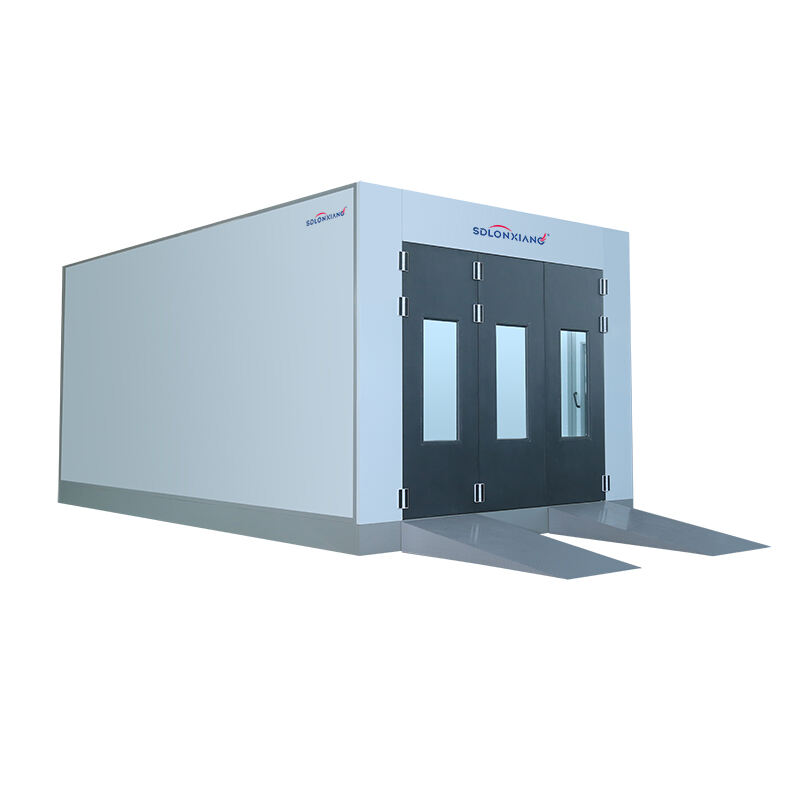

캐비닛용 도장 부스

캐비닛용 페인트 부스는 캐비닛 부품 및 가구 부품에 정밀하고 일관된 도장을 제공하도록 특별히 설계된 전문 산업용 마감 시스템입니다. 이 통제된 환경의 챔버는 목재, 금속 또는 복합 소재의 캐비닛에 락커, 착색제, 프라이머 및 탑코트와 같은 다양한 마감재를 도포하기 위한 최적의 조건을 조성합니다. 캐비닛용 페인트 부스는 정교한 환기 시스템을 통해 작동하여 균일한 페인트 분포를 보장하면서 동시에 스프레이 과잉 분사 입자와 휘발성 유기 화합물을 포집합니다. 최신형 캐비닛 페인트 부스는 첨단 여과 기술, 온도 조절 장치 및 조명 시스템을 통합하여 작업자가 항상 전문 수준의 마감 품질을 달성할 수 있도록 합니다. 이러한 시스템은 일반적으로 외부 공기를 정화하는 흡입 필터, 페인트 입자를 포집하는 배기 필터, 도장 공정 동안 일정한 공기 흐름을 유지하는 순환 팬을 갖추고 있습니다. 캐비닛용 페인트 부스 내부의 통제된 대기는 먼지 오염을 제거하고 습도 변동을 줄이며 페인트의 적절한 부착과 경화에 중요한 일정한 온도 조건을 제공합니다. 최신 모델 중 다수는 캐비닛 도어, 프레임 및 패널을 미리 설정된 속도로 지정된 도장 구역을 따라 이동시키는 자동 컨베이어 시스템을 포함합니다. 부스의 설계에는 폭발 방지 전기 부품, 화재 억제 시스템 및 비상 환기 제어 장치와 같은 안전 기능이 포함되어 작업자와 장비를 보호합니다. 고급 캐비닛용 페인트 부스 시스템은 환경 조건을 모니터링하고 생산 실적을 추적하며 유지보수 일정을 위한 진단 정보를 제공하는 컴퓨터 제어 패널과 통합되는 경우가 많습니다. 작업 공간 구성에는 일반적으로 작업자 플랫폼, 스프레이건 거치대, 재료 준비 구역 및 마감재 보관 공간이 포함됩니다. 이러한 정교한 마감 시스템은 다양한 캐비닛 크기와 구조를 수용하면서 장시간 생산 주기 동안에도 최적의 스프레이 패턴과 마감 품질을 유지합니다.