Ინდუსტრიული დასრულების ტექნოლოგიების გაგება

Არჩევანი შორის პუდრული დაფა ფხვნილოვანი და თხევადი საღებავის სისტემების არჩევა წარმოების და მრეწველობის ოპერატორებისთვის გადამწყვეტ გადაწყვეტილებას წარმოადგენს. ამ ორ განსხვავებულ საფარის ტექნოლოგიას თითოეულს აქვს თავისი უნიკალური უპირატესობები და კონკრეტული გამოყენების შესაძლებლობები, რაც არჩევანის პროცესს რთულს ხდის, თუმცა მაინც აუცილებელს ხდის ოპტიმალური შედეგების მისაღებად. როგორც კი მრეწველობა ივითარებს და გარემოსდაცვითი ნორმები მკაცრდება, ფხვნიოვან საფარსა და თხევად საღებავს შორის ძირეული განსხვავებების გააზრება increasingly important.

Მაისურის სისტემების მეცნიერული საფუძველი

Გამოყენების პროცესი და ტექნოლოგია

Მაისურის დასაფარად გამოიყენება მშრალი ფხვნილი ელექტროსტატიკური საღებავის დასაფარის პროცესით. ფხვნილის ნაწილაკები ელექტრულ მუხტს იღებს, ხოლო საფარზე ნულოვანი მუხტია მიმაგრებული, რაც ელექტრომაგნიტურ მიზიდულობას ქმნის და საფარზე განაწილების თანაბრობას უზრუნველყოფს. დაფარვის შემდეგ ნაწილი გამამტკიცებელ ღუმბაში შედის, სადაც ფხვნილი დნელდება და გადინებს, რის შედეგადაც მაგრი და თანაბარი საფარი მოიპოვებს.

Ტექნოლოგია იყენებს სპეციალურ სასრეიში pistolebi, რომლებიც აკონტროლებენ ფხვნილის დინებას და ნაწილაკების განაწილებას. თანამედროვე ფხვნილის საფარის სისტემები ხშირად შეიცავს ავტომატურ დამუშავების პროცესებს, რაც უზრუნველყოფს ერთგვაროვნობას დიდი სერიების დროს, ამცირებს ნარჩენებს და ამაღლებს ეფექტურობას.

Გარემოს დაცვისა და უსაფრთხოების სარგებელი

Ფხვნილის საფარის ერთ-ერთი ყველაზე მნიშვნელოვანი უპირატესობა მისი გარემოს დამცავი ბუნებაა. პროცესი არ გამოყოფს მახასიათებელ ნივთიერ ნაერთებს (VOCs), რაც უზრუნველყოფს მკაცრი გარემოსდაცვითი ნორმების დაცვას. გარდა ამისა, გამოუყენებელი ფხვნილი შეიძლება გამეორებით დამუშავდეს და ხელახლა გამოიყენოს, რის შედეგადაც მასალის გამოყენების მაჩვენებელი 98%-მდე იმატებს.

Მუშათა უსაფრთხოება უფრო მაღალია სითხის გამხსნელების არ გამოყენების და ალის საფრთხის შემცირებით. დახურული სისტემა ასევე ამცირებს ადამიანის კონტაქტს სავარაუდოდ ზიანს მიმდინარე ნივთიერებებთან, რის შედეგადაც იქმნება უფრო უსაფრთხო სამუშაო გარემო.

Სითხის საღებავის სისტემების გამოკვლევა

Ტრადიციული დამუშავების მეთოდები

Სითხის საღებავ სისტემებში გამოიყენება სხვადასხვა სპრეი ტექნოლოგიის საშუალებით დამუშავებული სითხის სალესები, მათ შორის მაღალი მოცულობის დაბალი წნევის (HVLP), ჰაერის გარეშე და ჰაერით დახმარებული ჰაერის გარეშე სისტემები. საღებავი შედგება მაღაროებისა და სმინებისგან, რომლებიც შეიცავს ხსნარს ან წყალზე დამყარებულ ტარას, რომელიც აორთქლდება გაშრობის პროცესში.

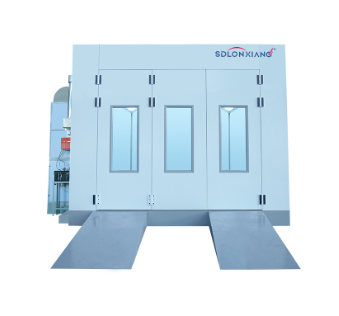

Თანამედროვე საღებავი გასაშრობი კამერები უზრუნველყოფს დახვეწის სისტემებსა და კლიმატის კონტროლს, რათა დაახლოებით გააუმჯობესონ გამოყენების პირობები და შეინახონ ზედმეტი საღებავი. ასეთი სისტემები შეიძლება შეიცავდეს სხვადასხვა სახის საფარი მასალებს, მარტივი საწყისი გამომცემლებიდან საუცხოო რთული მრავალსაფეხურიანი საფარით.

Მრავალფეროვნება და ფერის მართვა

Სითხის საღებავი ფერის შესატყვისებლად და სპეციალური სასრულის მისაღებად გთავაზობთ უმაღლეს მოქნილობას. საღებავი შეიძლება დამუშავდეს ადგილზე საჭირო ფერის მოსარგებლად, და შეცვლები შეიძლება სწრაფად მოხდეს სასურველი შედეგის მისაღებად. ეს მრავალფეროვნება სითხის საღებავს განსაკუთრებით ფასეულს ხდის იმ ინდუსტრიებში, სადაც ხშირად საჭიროა ფერის შეცვლა ან სპეციალური სასრულის გამოყენება.

Სხვადასხვა ფენების დასმის და უნიკალური ეფექტების შექმნის შესაძლებლობა სითხე საღებავს აძლევს უპირატესობას იმ შემთხვევებში, სადაც ესთეტიკური მოთხოვნები მთავარ როლს თამაშობს. სპეციალური მეტალიკური საფარი, მარგალიტის ეფექტი და ფერის შეცვლის საფარი უფრო იოლად მისაღებია სითხე საღებავის სისტემების გამოყენებით.

Ხარჯთა შედარება და ეკონომიკური ასპექტები

Საწყისი ინვესტიციის ანალიზი

Ფხვნილოვანი საღებავის სისტემები ხშირად მოითხოვენ უფრო მაღალ საწყის ინვესტიციებს სპეციალური მოწყობილობების საჭიროების გამო, მათ შორის საშრობი კამერები, აღდგენის სისტემები და გამამყარებელი ღუმბები. თუმცა, დიდი ვადით ექსპლუატაციის ხარჯები ხშირად უპირატესობას აძლევს ფხვნილოვან საღებავს მასალის უფრო მაღალი ეფექტურობისა და ნაკლები ნარჩენების განმართვის ხარჯების გამო.

Სითხე საღებავის სისტემებს სულ ჩათვლით უფრო დაბალი საწყისი ხარჯები ახლავთ, მაგრამ შესაძლოა მოთხოვნილი იყოს უფრო მომჭიდრო განიერებისა და გარემოს დაცვის კონტროლის სისტემები. სისტემებს შორის არჩევანი უნდა განხორციელდეს როგორც მიმდინარე ბიუჯეტური შეზღუდვების, ასევე დიდი ვადით ექსპლუატაციის ხარჯების გათვალისწინებით.

Ექსპლუატაციური ხარჯების შეფასება

Სამუშაო გამოყენების ხარჯები ორ ტექნოლოგიას შორის მნიშვნელოვნად განსხვავდება. ფხვნილოვანი საღებავის უნარი გამოუყენებელ მასალას ხელახლა გამოიყენებს შეიძლება მასალის დაზოგვა 30%-ზე მეტს უზრუნველყოს სითხე საღებავთან შედარებით. გარდა ამისა, ფხვნილოვანი საღებავის გამაგრების ენერგოხარჯი შეიძლება მაღალი იყოს, მაგრამ ეს ხშირად აისაბუთდება ნარჩენების განმარილებისა და გარემოსთან დაცვის ხარჯების შემცირებით.

Გადაწყვეტილების მიღებაში უნდა გაითვალისწინოთ სამუშაო ხელფასები და სწავლების მოთხოვნებიც. იმ შემთხვევაშიც კი, როდესაც ორივე სისტემა მოითხოვს კვალიფიციური ოპერატორებს, ფხვნილოვანი საღებავის გამოყენება საერთოდ იშვიათად მოითხოვს ცვლადებს და ხანგრძლივობის ერთგვაროვანი ხარისხის შენარჩუნებას უფრო მარტივს ხდის.

Სამუშაო და გამძლევადობის ფაქტორები

Ზედაპირის დამთავრების ხარისხი

Ფხვნილოვანი საღებავი უფრო სქელ და ერთგვაროვან საფარს ქმნის სითხე საღებავთან შედარებით, რაც განსაკუთრებით მაგარ და კოროზიამედეგ დასრულებას უზრუნველყოფს. ერთჯერადი დამუშავების პროცესი მაგარ დასრულებას ქმნის, რომელიც გარემოს მძიმე პირობებსა და ინტენსიურ გამოყენებას გაუძლებს.

Სითხე საღებავის სისტემები ასახელებენ ფინალური დამუშავების მიღწევას და საჭიროების შემთხვევაში უფრო თხელი საფარის მიღებას. ეს თვისება უფრო სასურველი ხდის სითხე საღებავს იმ აპლიკაციებში, სადაც წონა გადამწყვეტ ფაქტორს წარმოადგენს ან სადაც უნდა შეინარჩუნოთ დეტალების სირთულე.

Გრძელვადიანი მუშაობის მახასიათებლები

Ორივე ფინალური დამუშავების მეთოდი სწორად გამოყენების შემთხვევაში შეიძლება მიაწოდოს გრძელვადიანი დაცვა. ფხვნილოვანად დაფარული ზედაპირები საერთოდ უფრო მაღალ მექანიკურ მახასიათებლებს ამჟღავნებენ და უფრო მეტად არიან მდგრადი დაზიანების, ხაზების და ულტრაიისფერის სხივების მიმართ. სქელი, ერთგვაროვანი საფარი ქმნის დამცავ ბარიერს, რაც პროდუქტის სიცოცხლის ხანგრძლივობას ასახელებს.

Სითხე საღებავის სისტემები, განსაკუთრებით ახალგაზრდა ორკომპონენტიანი ფორმულების გამოყენებით, ბევრ აპლიკაციაში შეიძლება მიაწოდოს შედარებით მაღალი მდგრადობა. არჩევანი ხშირად დამოკიდებულია კონკრეტულ გარემოში გამოყენების პირობებზე და სერვისულ მოთხოვნებზე.

Სფეროების მითითებითი აპლიკაციები

Ავტომობილები და ტრანსპორტი

Ავტომობილების მრეწველობა იყენებს ორივე ტექნოლოგიას, თუმცა ფარდების დასამუშავებლად, თვითმბრუნავებისა და შასის კომპონენტებისთვის ხშირად ირჩევენ ფორთხილის საფარს. სითხე საღებავი კი გამოიყენება გარეგნული საფარისთვის, რადგან ის უმჯობეს უზრუნველყოფს მაღალი ბზინვარსა და ფერის სირთულეს.

Სავაჭრო სატრანსპორტო საშუალებების მწარმოებლები ხშირად არჩევენ ფორთხილის საფარს მძიმე მანქანებისა და საშენ ავტომობილებისთვის, სადაც გამძლეობა მთავარია. სქელი, დამცავი საფარი უზრუნველყოფს საუკეთესო წინააღმდეგობას ქვის და გზის ნარჩენების წინაშე.

Არქიტექტური და ინდუსტრიალური გამოყენება

Ფორთხილის საფარი გამოირჩევა არქიტექტურულ გამოყენებაში, განსაკუთრებით ალუმინის პროფილების, მარჯვებისა და გარე ავეჯის შემთხვევაში. საუკეთესო ამინდის წინააღმდეგ მდგრადობა და ფერის სტაბილურობა ხდის მას იდეალურს გარე გამოყენებისთვის, რომელიც გარკვეულ გარემოს უხეშ პირობებს ეხება.

Მრეწველობითი მოწყობილობების დამაგრების მწარმოებლები ხშირად ირჩევენ ფორთოხლის საღებავს მანქანების საყურადღებო და კომპონენტებისთვის, რომლებსაც სჭირდებათ განსაკუთრებით კარგი ქიმიური წინააღმდეგობა და მარაგი. კომპლექსური ფორმების მქონე საგნებზე გრძელვადიანი და ერთგვაროვანი საფარის მიღების შესაძლებლობა განსაკუთრებით შესაფერისს ხდის ამ გამოყენებებისთვის.

Ხშირად დასმული კითხვები

Როგორ ხდება გამაგრების დროს შედარება ფორთოხლის საღებავსა და სითხე საღებავს შორის?

Ფორთოხლის საღებავს საერთო გამაგრების დრო ჩვეულებრივ უფრო მოკლეა სითხე საღებავთან შედარებით. მიუხედავად იმისა, რომ ფორთოხლის საღებავს სჭირდება გამაგრების უფრო მაღალი ტემპერატურა, პროცესი ჩვეულებრივ დასრულდება 10-20 წუთში. სითხე საღებავს შეიძლება დასჭირდეს რამდენიმე საათი ან კვირა სრული გამაგრებისთვის, დამოკიდებულებით ფორმულირებაზე და გარემოს პირობებზე.

Შეიძლება თუ არა ფორთოხლის საღებავის გამოყენება ყველა მასალაზე?

Ფორთოხლის საღებავი საუკეთესოდ მუშაობს გამტარ მასალებზე, როგორიცაა ლითონები და ზოგიერთი განსაკუთრებით მომზადებული პლასტმასები. ის არ არის შესაფერისი იმ მასალებისთვის, რომლებიც ვერ გაუძლებენ საჭირო მაღალ გამაგრების ტემპერატურას (ჩვეულებრივ 350-400°F). სითხე საღებავს შეთავაზებული აქვს უფრო მაღალი მოქნილობა საბაზო მასალების თავსებადობის მიმართულებით.

Რომელი დასრულებაა უფრო გარემოს დამცავი?

Პროში საფარი ზოგადად უფრო გარემოს დამცავად ითვლება ნულოვანი VOC გამონაბოლქვის და გადამავალი საშრობის გადამუშავების შესაძლებლობის გამო. მიუხედავად იმისა, რომ წყალბაზის სითხე საღებავებმა გაუმჯობესა გარემოს დამცავი მახასიათებლები, ტრადიციული ხსნილების საშრობი საღებავები გარემოსთან დაკავშირებული გამოწვევები გრძელდება VOC გამონაბოლქვის და ნარჩენების განმართვის საჭიროების გამო.