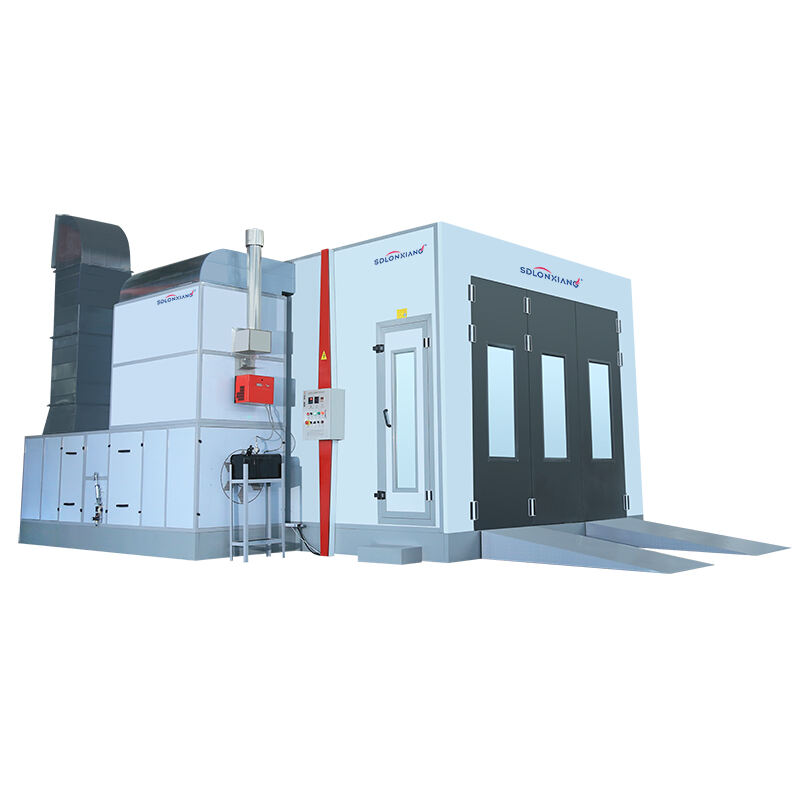

sUVペイントブース

SUV用ペイントブースは、スポーツユーティリティビークルの独自の寸法と要件に対応するために特別に設計された自動車仕上げソリューションです。この高度な塗装システムは、精密なエンジニアリングと最先端技術を組み合わせることで、大型車両への優れたコーティング結果を実現します。SUV用ペイントブースは拡大されたチャンバー構造を備えており、大型車両の移動や塗装作業に十分なスペースを提供すると同時に、塗装プロセス全体を通じて最適な空気流と温度管理を維持します。このシステムには、洗練された換気機構が組み込まれており、汚染を防ぎながらすべての車両表面に均一な塗布を実現するための一貫した空気循環を保証します。最新のSUV用ペイントブース構成では、過剰なスプレー粒子を捕集し、プロフェッショナルグレードの仕上げを得るために不可欠な清潔な作業環境を維持する高度なフィルター装置を採用しています。ブースの加熱および硬化機能は、大型車両の表面に対する熱的要件に対応するよう正確に調整されており、塗料の適切な密着性と耐久性を確保します。温度制御システムは、硬化工程中通常60〜80度の範囲で正確な環境条件を維持し、SUV外装における最適な塗料性能を得る上で極めて重要です。これらのブース内の照明設備には高輝度LEDアレイが採用されており、塗装プロセス中に卓越した視認性と色再現性を提供することで、技術者が不具合を特定し、均一な塗布を確実にすることができます。さらに、SUV用ペイントブースには、緊急時換気システム、消火機能、高所での車両作業を行う塗装専門家にとって安全な操作を可能にする人間工学に基づいた設計要素など、さまざまな安全機能も備えられています。