יצרן קבינת דיווח על רכב

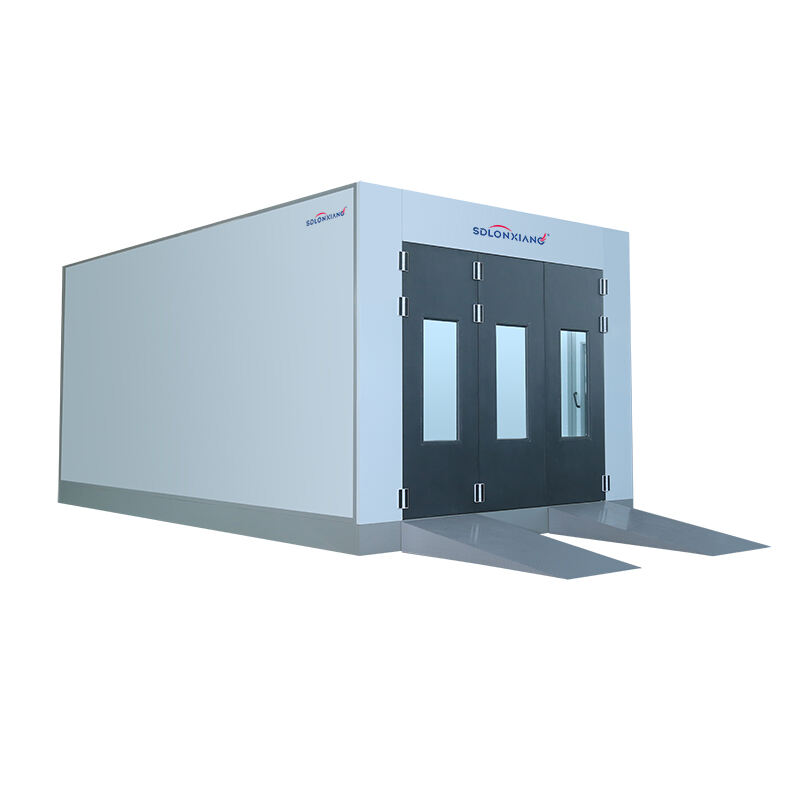

יצרן דוכני ריסוס לצביעה של רכב מייצג את עמוד התווך של תהליכי הגימור האוטומotive המודרניים, ומציע פתרונות מקיפים לתהליכי צביעה מקצועיים של כלי רכב. יצרנים מיוחדים אלה מעצבים ומיproducים סביבות צביעה סגורות המבטיחות תנאי עבודה אופטימליים להחלת ציפויים אוטומotive בדיוק ובהתמדה. יצרן דוכני ריסוס לצביעה של רכב יוצר מערכות הכוללות טכנולוגיית תקיפה מתקדמת, מנגנוני בקרת טמפרטורה ומערכות סינון לשמירה על זרימת אויר נקי לאורך תהליך הצביעה. היצרנים הללו מבינים את הדרישות הקריטיות של צביעה אוטומotive, כולל הסרת אבק, איסוף ריסוס יתר, והפצת אויר אחידה שמבטיחה איכות גימור גבוהה. הפונקציות העיקריות של הציוד שיוצר יצרן דוכני ריסוס לצביעה של רכב כוללות יצירת סביבת לחץ אויר חיובי, שימור טווח טמפרטורה קבוע של 65-80 מעלות פרנהייט, ותאורה מספקת לצורך התאמת צבע מדויקת. התכונות הטכנולוגיות המשולבות על ידי חברות מובילות של יצרני דוכני ריסוס לצביעה של רכב כוללות מערכות בקרה ממוחשבות, אלמנטים חימום חסכוניים באנרגיה, תהליכי סינון רב שלביים ותחנות ניקוי אוטומטיות של אקדחי ריסוס. היצרנים הללו משתמשים בחומרים מתקדמים כגון עמידה מגולוונת, משטחים עם ציפוי אבקה ומסנני אויר לחלקיקים בעלי יעילות גבוהה, כדי להבטיח עמידות וחיים ארוכים של הביצועים. יישומים של מוצרים מיצרני דוכני ריסוס לצביעה של רכב משתרעים על פני דוכני רכב, מוסכי תיקון עצמאיים, מתקני תחזוקת צי ומרכזי שינוי רכב ייחודיים. הגיוון של המערכות שיוצר יצרן מוכשר של דוכני ריסוס לצביעה של רכב מאפשר צביעה של מגוון סוגי רכבים, ממכוניות קטנות ועד למשאיות מסחריות ורכבים מיוחדים. פתרונות מודרניים של יצרני דוכני ריסוס לצביעה של רכב כוללים תכונות של עמידה בדרישות סביבתיות, התאמה לתקני פליטה קפדניים ולאילוצי ניהול פסולת, תוך מירב של יעילות תפעולית ושל הוראות בטיחות לעובדים.