נורת צבע חשמלית

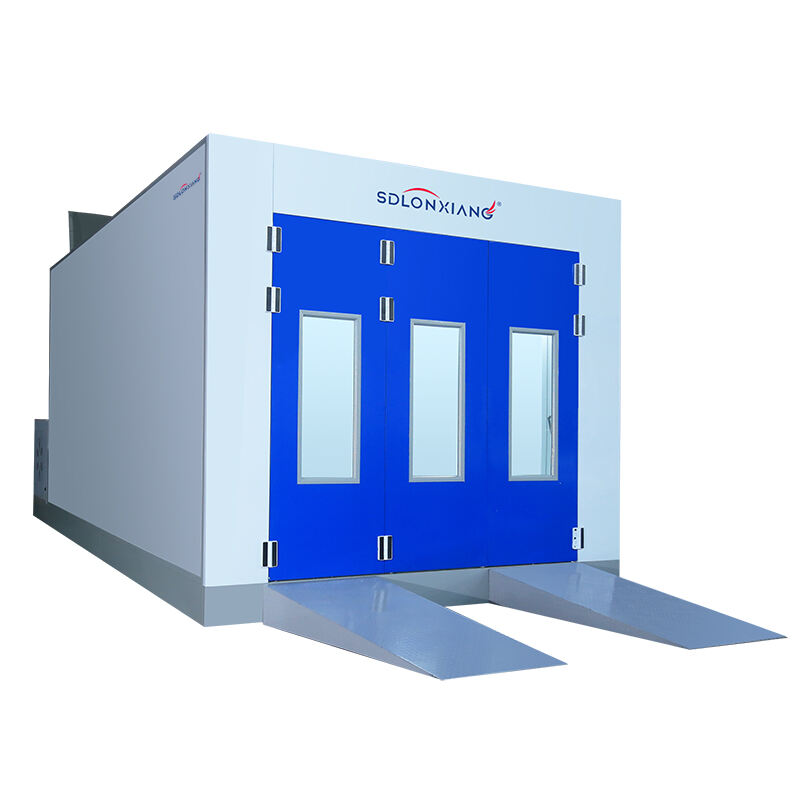

תא דיוור חשמלי מייצג מערכת שילוב ובקרה מתקדמת שתוכננה במיוחד לדיור מחדש של רכב, יישומים תעשייתיים של ציפוי ותהליכי ייצור. ציוד מתקדם זה יוצר סביבה מבוקרת המבטיחה יישום ציפוי אופטימלי, תוך שמירה על תקנים של ביטחון ותאימות סביבתית. התא החשמלי פועל באמצעות מערכת הזרמת אויר מתקדמת אשר מוציאה אויר מזוהם מהמרחב העבודה, מסננת אותו במספר שלבים, ומספקת אויר נקי, מבוקר בטמפרטורה, לצורך תוצאות ציפוי מיטביות. מערכות תא דיוור חשמלי מודרניות כוללות טכנולוגיה מתקדמת הכוללת מאווררים במהירות משתנה, בקרות דיגיטליות ומערכות ניטור אוטומטיות שעוקבות ברציפות אחר מהירות האויר, טמפרטורה ורמות רטיבות. היחידות מצטיינות בבנייה עמידה עם מסגרות נחושת מופזלות, תאורת LED להצצה מעולה, ורכיבי חשמל עמידים בפיצוץ המקיימים תקנים מחמירים של ביטחון. תהליך הסינון כולל בדרך כלל מסנני טרום אשר תופסים חלקיקים גדולים, ולאחריהם מסננים בעלי יעילות גבוהה אשר מסירים זיהומים עדינים וחומרי ספיגת יתר. דגמים מתקדמים של תאי דיוור חשמלי כוללים מערכות שחזור חום אשר מחזירות אויר חם, מפחיתות את צריכה האנרגיה תוך שמירה על טמפרטורות פעולה אופטימליות. התכונות הטכנולוגיות מתרחבות לכולל בקרים לוגיים מתוכנתים המאפשרים למשתמשים להתאים תבניות זרימת אויר, הגדרות טמפרטורה ולוחות פעילות בהתאם לדרישות הציפוי הספציפיות. היישומים משתרעים על פני חנויות תיקון רכב, מתקני ייצור, תעשייה אווירונאוטית, פעולות ציפוי ימיות וסדנאות ייצור מותאמות. התא החשמלי מהווה רכיב חיוני לעסקים הדורשים יכולות סיום ברמה מקצועית, ומבטיח איכות עקיבה, תוך הגנה על עובדים מפני אדים מזיקים ושימור תאימות עם תקנות סביבתיות. מערכות אלו מותאמות לגודלי פרויקטים שונים, החל מחלקי רכב קטנים ועד רכיבים תעשייתיים גדולים, מה שהופך אותן לפתרונות גמישים לצרכי ציפוי מגוונים.