מערכות בטיחות והגנה על הסביבה מקיפות

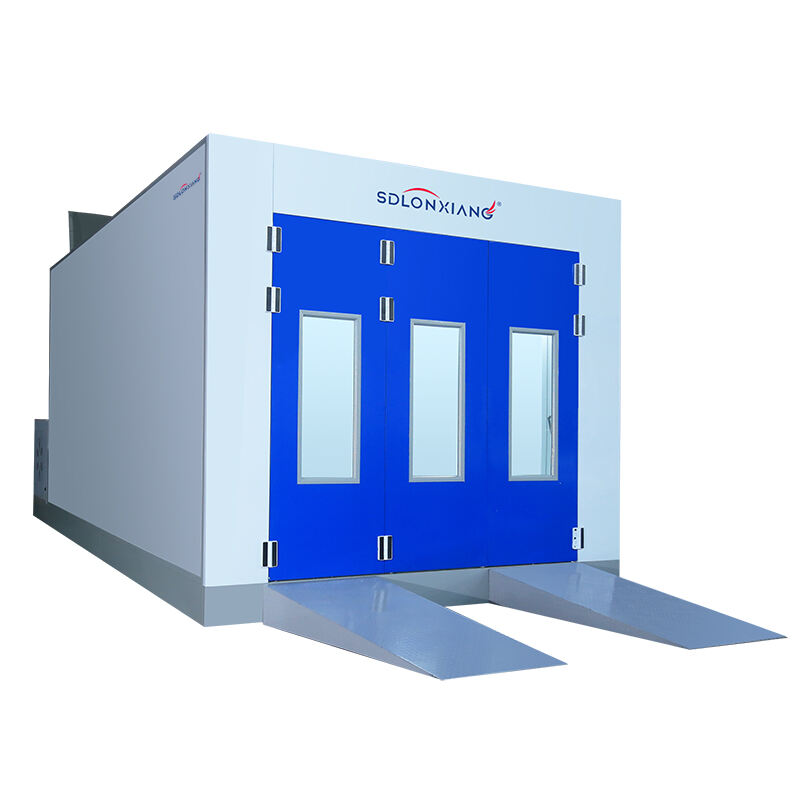

בתי ריסוס אוטומטיים כוללים מערכות שלמות של ביטחון ו הגנה על הסביבה שמגדירות תקנים מובילים בענף להגנת מפעילים ואחידות עם דרישות רגולטוריות בפעולות צביעה אוטומotive. מסגרת הביטחון כוללת שכבות מגן מרובות, ביניהן מערכות חשמל עמידות לפיצוצים, טכנולוגיית כיבוי אש, בקרות באור כללי חירום, ואיתור אדים מסוכנים שנועדו למחוק סיכונים הקשורים בתהליכי יישום צבע. גופי תאורה ורכיבים חשמליים עמידים לפיצוצים עומדים בדרישות קפדניות של תקני ביטחון בסביבות מסוכנות בהן נמצאים אדים וחלקיקים łatים להבערה. המערכות החשמליות משתמשות בארונות סגורים מיוחדים, תעלות ומנגנוני החלפה המונעים מקורות הצתה תוך שמירה על תאורה מספקת ליישום צבע איכותי. מערכות כיבוי האש כוללות חיישני זיהוי אוטומטיים, חומריức כיבוי ואסטרטגיות תגובה לשעת חירום המופעלות מיד עם זיהוי תנאי שריפה. מערכות אוורור חירום מספקות יכולת החלפת אויר מהירה המסירה במהירות אטמוספירות מסוכנות ומייצרת תנאים בטוחים לחיפוש ובריחה של המפעילים. מסגרת ההגנה על הסביבה כוללת מערכות פילטרים מתקדמות שאוספות חלקיקי צבע, תרכובות אורגניות נדיפות ושאר הפליטות לפני שחרור האויר לאטמוספירה. טכנולוגיית פילטרים רב-שלבית מסירה חלקיקים בגודל משתנה, בעוד שמערכות פחמת פעילה סופגות אדים וכימיקלים וריחות. עיצוב האיטום מונע מהרסס לצאת מחוץ לאזור התא, ומגן על הציוד והאזורים הסמוכים מלכלוך. מערכות ניטור אוטומטיות עוקבות באופן מתמיד אחר איכות האוויר, הפרשי לחץ ורמות הפליטה כדי להבטיח עמידה בתקנות סביבתיות. מערכות הביטחון כוללות דרישות לציוד הגנה אישי, פרוטוקולי הדרכה וاجراءי חירום המגנים על עובדים מפני חשיפה לחומרים מסוכנים. נעילי אוורור מונעים הפעלה של התא כאשר תנאי הביטחון אינם מתקיימים, ובכך מבטיחים שהמפעילים לא יוכלו ליצור מצבים מסוכנים במקרה. מערכות ההגנה על הסביבה מאפשרות לעסקים לפעול בהתאם לתקנות מקומיות, מדינתיות וunreadederal תוך הדגשת אחריות קורפורטיבית. חשיבות מערכות ההגנה הכוללות האלה מתרחבת גם לציות משפטי, דרישות ביטוח, ביטחון עובדים ויחסים עם הקהילה. עסקים נהנים מחשיפה מופחתת לנזקים, פרמיות ביטוח נמוכות יותר ושיפור בשמורה על עובדים בעזרת שיפור תנאי הביטחון. הערך המוצע כולל הבטחת עמידה בתקנות, השפעה סביבתית מופחתת, שיפור תרבות הביטחון במקום העבודה, ושיפור מוניטין העסק שמושך עובדים איכותיים ולקוחות בעלי דאגה לסביבה.