Opzioni di configurazione flessibili

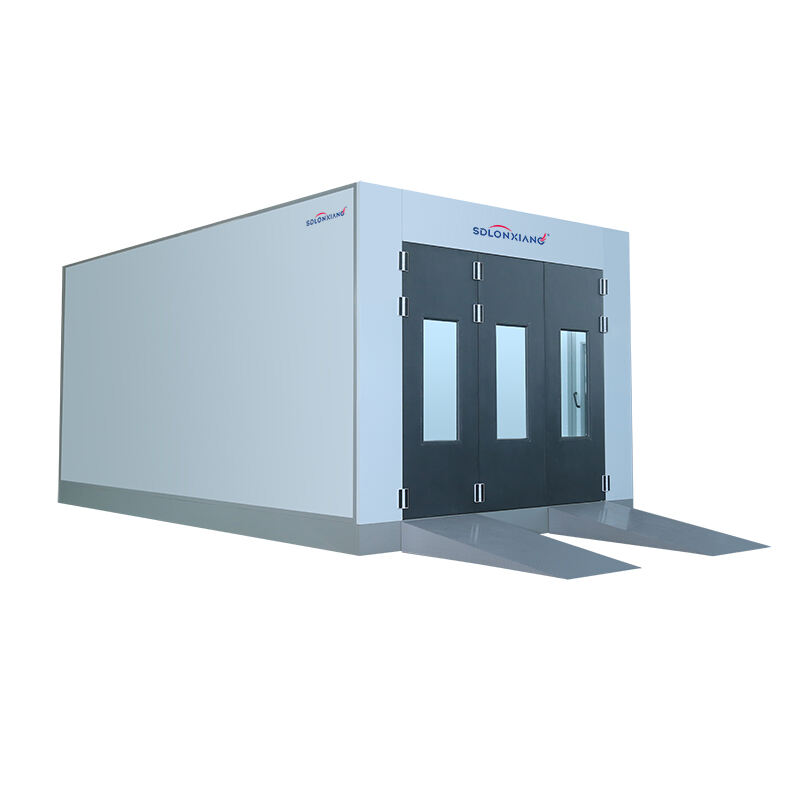

La flessibilità della cabina di verniciatura manuale rappresenta un vantaggio trasformativo che si adatta perfettamente a diverse esigenze operative, consentendo alle aziende di massimizzare il proprio investimento gestendo al contempo le mutevoli richieste produttive e le specifiche variabili dei progetti. La filosofia progettuale modulare permette ai clienti di configurare con precisione le dimensioni della cabina in base allo spazio disponibile e alle dimensioni tipiche dei pezzi da lavorare, garantendo un utilizzo ottimale delle risorse impiantistiche senza compromettere la funzionalità. I sistemi a pannelli espandibili consentono modifiche future in risposta all'evoluzione delle esigenze aziendali, offrendo scalabilità che protegge il valore dell'investimento a lungo termine ed evita le interruzioni e i costi associati alla sostituzione completa del sistema. Le configurazioni delle porte offrono diverse opzioni, tra cui pannelli scorrevoli, a battente o rimovibili, che facilitano la movimentazione dei materiali e l'accesso agli equipaggiamenti mantenendo al contempo l'integrità del contenimento durante il funzionamento. Le regolazioni in altezza consentono di accogliere prodotti che vanno da piccoli componenti ad assemblaggi di grandi dimensioni, mentre le modifiche in larghezza e profondità assicurano un utilizzo efficiente dello spazio disponibile, indipendentemente dai vincoli strutturali. La progettazione della cabina di verniciatura manuale include sezioni rimovibili che permettono l'accesso per la manutenzione e la sostituzione dei componenti senza richiedere lo smontaggio della cabina, riducendo al minimo i tempi di fermo e i costi di assistenza. Le soluzioni di illuminazione possono essere personalizzate per fornire un'illuminazione ottimale per applicazioni specifiche, con opzioni relative a diverse temperature di colore e livelli di intensità che migliorano l'accuratezza nell'abbinamento dei colori e la capacità di rilevamento dei difetti. Le configurazioni elettriche si adattano a diverse esigenze di alimentazione e classificazioni di sicurezza, garantendo la compatibilità con le infrastrutture esistenti dell'impianto e il rispetto delle normative e dei codici applicabili. La capacità di ventilazione può essere regolata in base alle dimensioni della cabina e alle esigenze applicative, ottimizzando il consumo energetico pur mantenendo le prestazioni necessarie in termini di sicurezza e impatto ambientale. La flessibilità si estende anche alle procedure operative, consentendo alla stessa cabina di verniciatura manuale di gestire rivestimenti a base acquosa, finiture a base solvente e materiali speciali mediante opportuni aggiustamenti dei filtri e della ventilazione. Questa adattabilità elimina la necessità di sistemi specializzati multipli, riducendo l'investimento iniziale e i requisiti di spazio impiantistico, offrendo al contempo capacità complete di verniciatura. Le opzioni per le superfici di lavoro includono grate rimovibili, piattaforme girevoli e dispositivi di fissaggio regolabili, che si adattano a diversi tipi di prodotto e tecniche di verniciatura, migliorando l'efficienza dell'operatore e la qualità del rivestimento in applicazioni diverse.