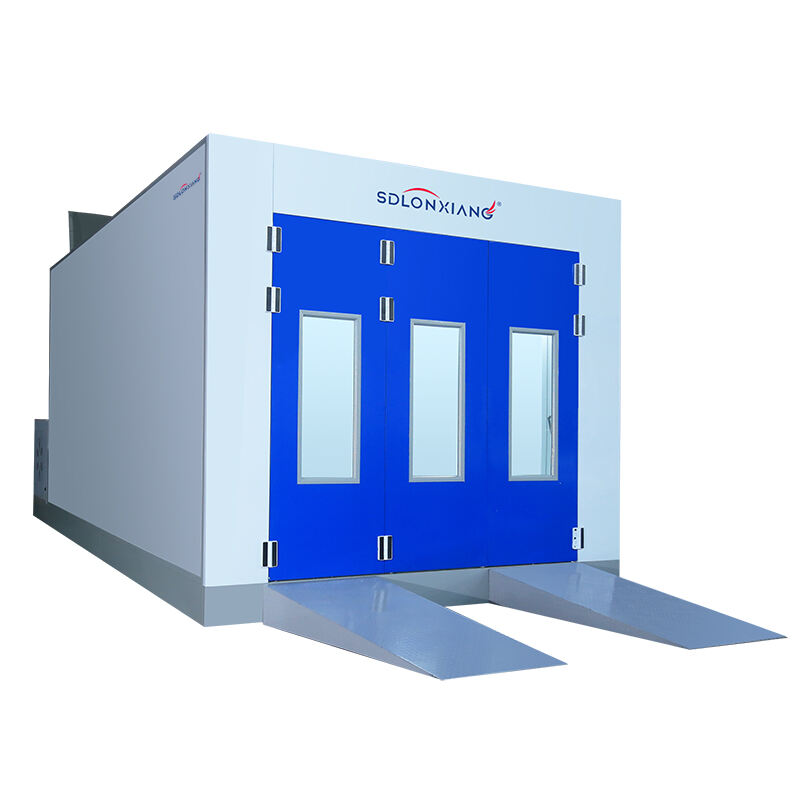

proizvođači kabina za farbanje

Proizvođači kabina za natapanje predstavljaju temelj moderne industrijske obrade završnih površina, pružajući ključnu opremu koja osigurava sigurno, učinkovito i visokokvalitetno nanošenje premaza u brojnim industrijama. Ove specijalizirane tvrtke projektiraju, inženjerski razvijaju i proizvode sofisticirane sustave za zatvaranje kojima se kontroliraju lebdeće čestice, kemijske pare i raspršeni premaz tijekom procesa bojanja, nanošenja praha i drugih postupaka obrade površina. Glavna funkcija proizvođača kabina za natapanje je stvaranje zatvorenih okruženja u kojima operateri mogu nanositi premaze uz održavanje optimalne kvalitete zraka, kontrole temperature i sigurnosnih standarda. Njihovi proizvodi kreću se od malih kabina za popravak boje na automobilima do ogromnih industrijskih instalacija sposobnih primiti zrakoplove, tešku mehanizaciju i komponente velikih proizvodnih linija. Moderni proizvođači kabina za natapanje integriraju napredne tehnologije uključujući ispušne ventilatore s varijabilnom brzinom, sofisticirane filtrace sustave i računalizirane kontrolne sustave okoline koji nadziru temperaturu, vlažnost i uzorke cirkulacije zraka. Ove tehnološke značajke osiguravaju dosljednu kvalitetu premaza, istovremeno zaštićujući radnike od opasnih isparenja i osiguravajući sukladnost s ekološkim propisima. Primjena proizvoda proizvođača kabina za natapanje obuhvaća automobilsku poliranu obradu, proizvodnju zrakoplova, proizvodnju namještaja, premazivanje brodova, završnu obradu poljoprivredne opreme i brojne druge industrijske sektore koji zahtijevaju preciznu obradu površina. Vodeći proizvođači kabina za natapanje pružaju i sveobuhvatne usluge uključujući instalaciju, obuku, održavanje i podršku u pogledu sukladnosti s propisima, osiguravajući svojim klijentima maksimalnu produktivnost i sigurnosne standarde tijekom cijelog vijeka trajanja opreme.