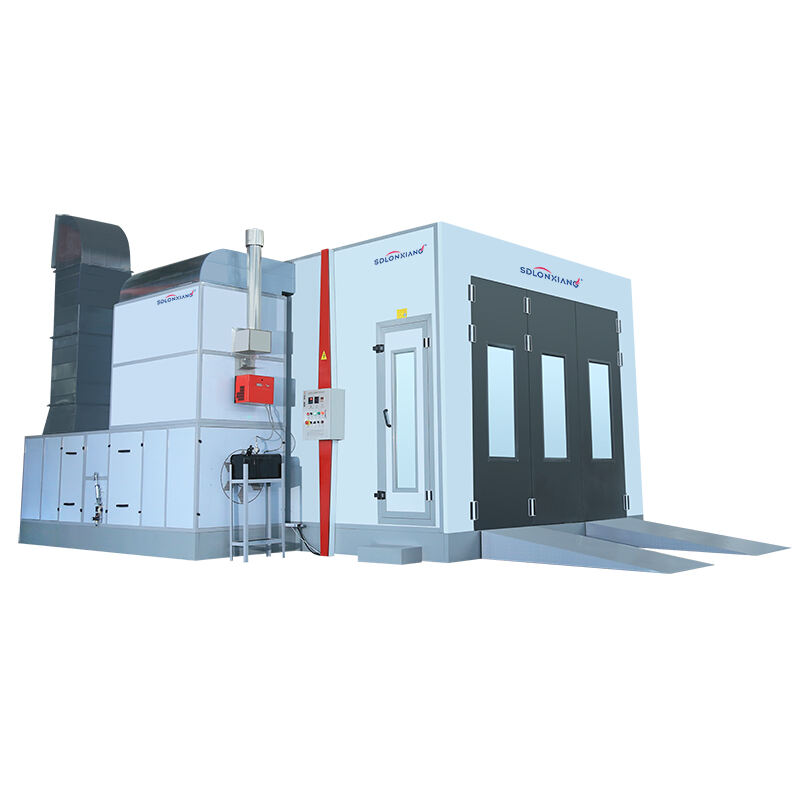

αυστραλιανός θάλαμος βαφής

Η αυστραλιανή θάλαμος βαψίματος αποτελεί μια εξελιγμένη λύση για αναζωογόνηση αυτοκινήτων και βιομηχανικές εφαρμογές επικάλυψης, σχεδιασμένη ειδικά για να ανταποκρίνεται στις απαιτητικές προδιαγραφές επαγγελματικών εργασιών βαψίματος. Αυτός ο εξειδικευμένος εξοπλισμός δημιουργεί ένα ελεγχόμενο περιβάλλον στο οποίο οχήματα, μηχανήματα και διάφορα εξαρτήματα μπορούν να επικαλυφθούν με βαφή υψηλής ποιότητας, με εξαιρετικά αποτελέσματα. Ο αυστραλιανός θάλαμος βαψίματος διαθέτει προηγμένα συστήματα διαχείρισης ροής αέρα που εξασφαλίζουν τη βέλτιστη κατανομή της βαφής, διατηρώντας παράλληλα σταθερές τις συνθήκες θερμοκρασίας και υγρασίας καθ' όλη τη διάρκεια της διαδικασίας βαψίματος. Οι σύγχρονοι σχεδιασμοί του αυστραλιανού θαλάμου βαψίματος περιλαμβάνουν εξοπλισμό κορυφαίας τεχνολογίας φιλτραρίσματος που απορροφά τα σωματίδια υπερβολικού ψεκασμού και τις πτητικές οργανικές ενώσεις, δημιουργώντας ένα καθαρότερο περιβάλλον εργασίας για τους χειριστές. Η κατασκευή του θαλάμου περιλαμβάνει χάλυβα με ενίσχυση και μονωτικές πλάκες που παρέχουν εξαιρετικές θερμικές ιδιότητες και ικανότητες μείωσης θορύβου. Τα συστήματα ελέγχου θερμοκρασίας στον αυστραλιανό θάλαμο βαψίματος διασφαλίζουν ακριβείς λειτουργίες θέρμανσης και ψύξης, επιτρέποντας τη σωστή διαδικασία ξήρανσης της βαφής και την άριστη ποιότητα τελικής επίστρωσης. Ο σχεδιασμός ροής αέρα δημιουργεί περιβάλλον θετικής πίεσης που εμποδίζει την είσοδο ρύπων στον χώρο εργασίας, ενώ απομακρύνει αποτελεσματικά τις αναθυμιάσεις και τα σωματίδια της βαφής. Οι εγκαταστάσεις αυστραλιανού θαλάμου βαψίματος συνήθως διαθέτουν ενεργειακά αποδοτικά φωτιστικά συστήματα που παρέχουν ομοιόμορφο φωτισμό χωρίς να δημιουργούν ζώνες υπερθέρμανσης ή σκιές κατά τη διάρκεια της διαδικασίας βαψίματος. Το σύστημα εξαερισμού περιλαμβάνει πολλαπλά στάδια φιλτραρίσματος, συμπεριλαμβανομένων φίλτρων εισαγωγής που καθαρίζουν τον εισερχόμενο αέρα και φίλτρων εξαγωγής που απορροφούν τα σωματίδια βαφής πριν ο αέρας εγκαταλείψει την εγκατάσταση. Αυτοί οι θάλαμοι μπορούν να φιλοξενήσουν διάφορα μεγέθη οχημάτων και βιομηχανικών εξαρτημάτων, καθιστώντας τους ευέλικτες λύσεις για εργαστήρια επισκευής αυτοκινήτων, βιομηχανικές εγκαταστάσεις και εργασίες προσαρμοσμένου βαψίματος. Η τεχνολογία του αυστραλιανού θαλάμου βαψίματος περιλαμβάνει προγραμματιζόμενα συστήματα ελέγχου που επιτρέπουν στους χειριστές να ρυθμίζουν τη θερμοκρασία, τη ροή αέρα και τις χρονικές παραμέτρους, ανάλογα με τις συγκεκριμένες απαιτήσεις βαφής και τις περιβαλλοντικές συνθήκες.