Fortgeschrittene thermische Härtetechnologie

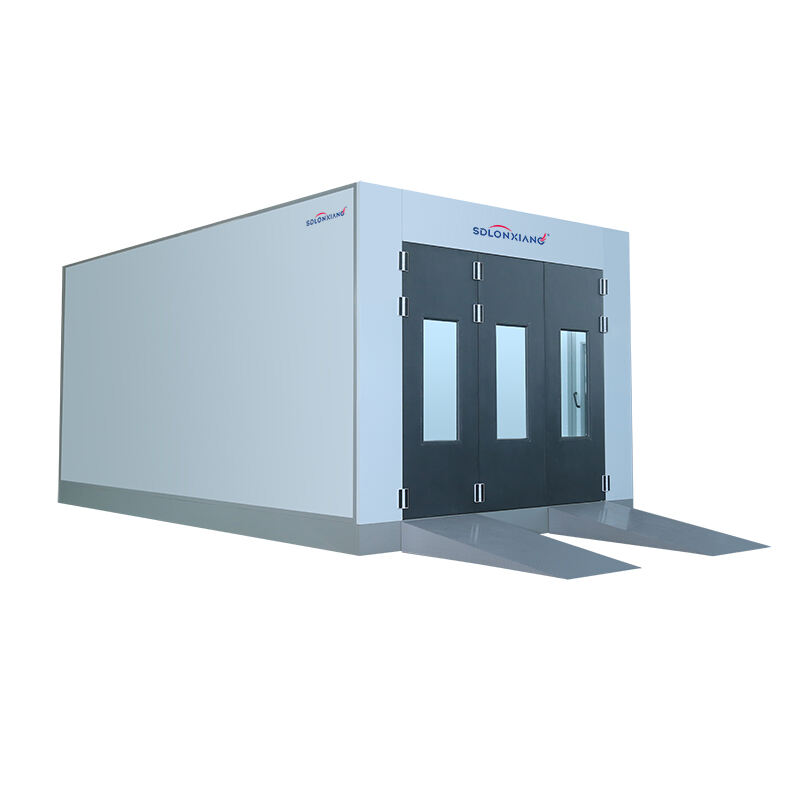

Die fortschrittliche Wärmeaushärtungstechnologie, die in der Lagerung von Backlack für Automobile eingebettet ist, revolutioniert, wie Autolackierungen ihre endgültigen Eigenschaften und Leistungsmerkmale erreichen. Dieser anspruchsvolle Prozess beinhaltet eine präzise Temperaturkontrolle, die spezifische chemische Reaktionen innerhalb der Lackschichtmatrix aktiviert und molekulare Vernetzungen erzeugt, welche die mechanischen Eigenschaften der Beschichtung erheblich verbessern. Im Gegensatz zu herkömmlichen Lufttrocknungslacken, die ausschließlich auf Lösungsmittelverdunstung und Oxidation zur Aushärtung angewiesen sind, nutzt der im Lager befindliche Backlack gezielte Wärmezufuhr, um Polymerisationsreaktionen auszulösen, die stärkere und haltbarere chemische Bindungen bilden. Der thermische Aushärtungsprozess findet typischerweise in speziellen Lackierkabinen statt, die mit präzisen Temperaturüberwachungssystemen ausgestattet sind und eine gleichmäßige Wärmeverteilung über die lackierte Oberfläche sicherstellen. Diese kontrollierte Umgebung eliminiert Variablen, die die Aushärtungskonsistenz beeinträchtigen können, wie beispielsweise Umgebungsfeuchtigkeit und Temperaturschwankungen, die häufig herkömmliche Lackanwendungen beeinträchtigen. Die Technologie hinter dem im Lager befindlichen Backlack integriert duromere Harze, die bei Raumtemperatur stabil bleiben, aber bei bestimmten Temperaturbereichen aktiviert werden. Diese Eigenschaft ermöglicht eine verlängerte Verarbeitungszeit während des Auftrags, gewährleistet jedoch eine vollständige Aushärtung, sobald der thermische Prozess beginnt. Die molekulare Umstrukturierung, die beim Backen stattfindet, erzeugt ein dreidimensionales Polymernetzwerk, das eine überlegene Beständigkeit gegenüber mechanischer Beanspruchung, chemischen Angriffen und Umwelteinflüssen aufweist. Fachmaler schätzen, dass diese Technologie häufige Oberflächenfehler wie Lösungsmittelausblähungen, schlechte Fließfähigkeit und unvollständige Aushärtung vermeidet, wie sie bei herkömmlichen Lacken auftreten können. Das vorhersagbare Aushärtungsverhalten des im Lager befindlichen Backlacks ermöglicht eine präzise Planung und Qualitätskontrolle in Produktionsumgebungen und macht ihn ideal für hochvolumige Automobil-Refinishing-Anwendungen, bei denen Konsistenz und Effizienz oberste Priorität haben.