কাস্টমাইজযোগ্য পরিবেশগত নিয়ন্ত্রণ সমাধান

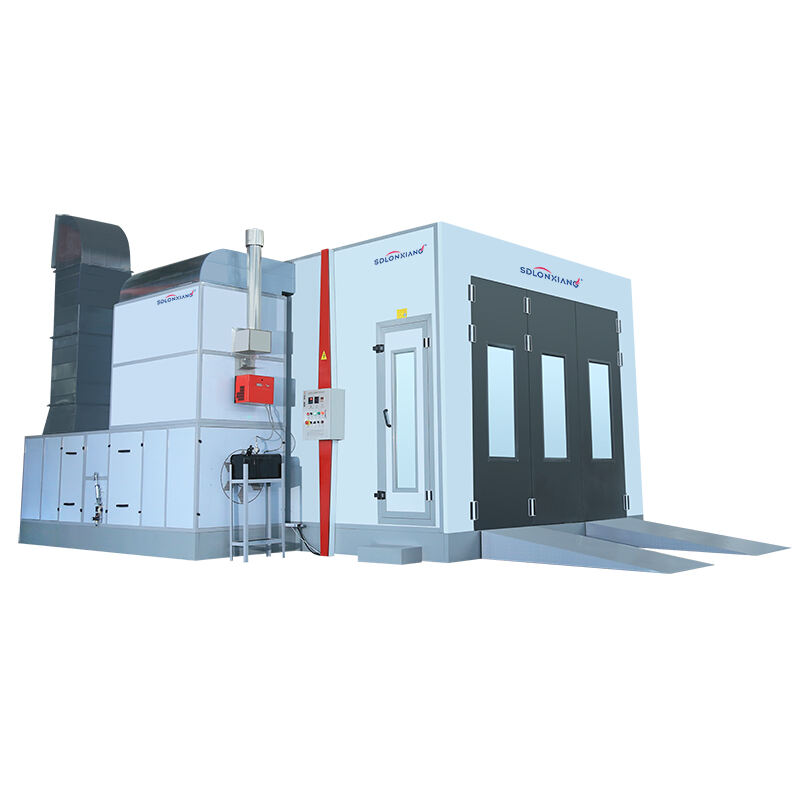

প্রমুখ পেইন্ট বুথ প্যানেল সরবরাহকারী কোম্পানি বিভিন্ন শিল্প এবং প্রয়োগের চাহিদা দ্বারা উপস্থাপিত অনন্য চ্যালেঞ্জগুলি মোকাবেলার জন্য কাস্টমাইজযোগ্য পরিবেশগত নিয়ন্ত্রণ সমাধান প্রদানে উত্কৃষ্ট। এই উন্নত সিস্টেমগুলি মৌলিক প্যানেল নির্মাণের চেয়ে অনেক বেশি, যা স্প্রে বুথের পরিবেশে বায়ুর গুণমান, তাপমাত্রা নিয়ন্ত্রণ এবং দূষণ প্রতিরোধকে অনুকূলিত করে এমন উন্নত প্রযুক্তি অন্তর্ভুক্ত করে। পেশাদার পেইন্ট বুথ প্যানেল সরবরাহকারী প্রতিষ্ঠানগুলি বুঝতে পারে যে বিভিন্ন কোটিং প্রক্রিয়ার জন্য নির্দিষ্ট পরিবেশগত অবস্থা প্রয়োজন, এবং তারা একীভূত ফিল্টারেশন পয়েন্ট, বায়ুপ্রবাহ ব্যবস্থাপনা বৈশিষ্ট্য এবং চাপ নিয়ন্ত্রণ ব্যবস্থার মাধ্যমে এই বিভিন্ন প্রয়োজনীয়তা পূরণের জন্য প্যানেল সিস্টেম ডিজাইন করে। অভিজ্ঞ পেইন্ট বুথ প্যানেল সরবরাহকারী কোম্পানির কাছ থেকে পাওয়া কাস্টমাইজেশন সুবিধাগুলিতে নির্দিষ্ট রাসায়নিকের বিরুদ্ধে প্রতিরোধী বিশেষ প্যানেল কোটিং, গুণগত নিয়ন্ত্রণের জন্য আদর্শ আলোকসজ্জা প্রদানকারী একীভূত আলোক ব্যবস্থা এবং কার্যকর কর্মপ্রবাহ প্যাটার্নকে সহজতর করার জন্য প্রবেশাধিকার কনফিগারেশন অন্তর্ভুক্ত থাকে। এই সরবরাহকারীরা তাদের নির্দিষ্ট উৎপাদনের চাহিদা, নিয়ন্ত্রক অনুপালনের প্রয়োজনীয়তা এবং কার্যকরী সীমাবদ্ধতা বোঝার জন্য গ্রাহকদের সাথে ঘনিষ্ঠভাবে কাজ করে, যা কর্মক্ষমতা এবং খরচ-কার্যকারিতা উভয়কেই অনুকূলিত করে এমন কাস্টমাইজড সমাধান তৈরি করে। উন্নত পরিবেশগত মনিটরিং ক্ষমতা প্যানেল সিস্টেমে একীভূত করা যেতে পারে, যা কোটিংয়ের গুণমান এবং কর্মীদের নিরাপত্তাকে প্রভাবিত করে এমন বায়ুর গুণমান, তাপমাত্রা, আর্দ্রতা এবং চাপের অবস্থার উপর বাস্তব-সময়ের প্রতিক্রিয়া প্রদান করে। পেইন্ট বুথ প্যানেল সরবরাহকারী কোম্পানি বিশেষ ভেন্টিলেশন একীভূতকরণ বৈশিষ্ট্যও প্রদান করে যা তাপ পুনরুদ্ধার সিস্টেম এবং চলমান গতির ফ্যান নিয়ন্ত্রণের মাধ্যমে শক্তি খরচ কমিয়ে সঠিক নিষ্কাশন বায়ু ব্যবস্থাপনা নিশ্চিত করে। আধুনিক প্যানেল ডিজাইনে অন্তর্নিহিত নমনীয়তা পেইন্ট বুথ প্যানেল সরবরাহকারী সংস্থাগুলিকে ভবিষ্যতের সম্প্রসারণের প্রয়োজনীয়তা পূরণ করতে দেয়, যা গ্রাহকদের উৎপাদনের চাহিদা অনুযায়ী বুথের কনফিগারেশন পরিবর্তন করতে দেয় যাতে পুরো সিস্টেম প্রতিস্থাপনের প্রয়োজন হয় না। এই পরিবেশগত নিয়ন্ত্রণ সমাধানগুলিতে একীভূত গুণগত নিয়ন্ত্রণ বৈশিষ্ট্যগুলিতে কণা মনিটরিং সিস্টেম, বাষ্প সনাক্তকরণ ক্ষমতা এবং স্বয়ংক্রিয় অ্যালার্ট ব্যবস্থা অন্তর্ভুক্ত থাকে যা অপারেটরদের অবহিত করে যখন অবস্থা আদর্শ প্যারামিটার থেকে বিচ্যুত হয়। পরিবেশগত ব্যবস্থাপনার এই প্রাকৃতিক পদ্ধতি কোটিং ত্রুটি প্রতিরোধ করতে সাহায্য করে এবং বুথ অপারেটরদের জন্য নিরাপদ কর্মস্থল বজায় রাখে। তদুপরি, অনেক পেইন্ট বুথ প্যানেল সরবরাহকারী কোম্পানি শক্তি দক্ষতা অনুকূলকরণ পরিষেবা প্রদান করে যা উন্নত তাপ নিরোধক বৈশিষ্ট্য, উন্নত বায়ু ব্যবস্থাপনা সিস্টেম এবং বুদ্ধিমান নিয়ন্ত্রণ প্রযুক্তির মাধ্যমে প্রকৃত উৎপাদনের চাহিদা অনুযায়ী সিস্টেম অপারেশন সামঞ্জস্য করে পরিচালন খরচ কমায়।