When industrial operations require high-quality finishing capabilities, selecting the right equipment becomes a critical business decision. Paint booths for sale represent a significant investment that directly impacts productivity, quality standards, and regulatory compliance. Understanding the essential specifications enables buyers to make informed choices that align with their operational requirements and long-term goals. The complexity of modern paint booth systems demands careful evaluation of multiple technical parameters before committing to a purchase decision.

The paint booth market offers diverse solutions ranging from basic spray environments to sophisticated automated systems. Each configuration serves specific applications, from automotive refinishing to industrial coating operations. Buyers must navigate through various technical specifications while considering factors such as throughput requirements, space constraints, and budget limitations. The decision-making process becomes more challenging when evaluating paint booths for sale from different manufacturers, each promoting unique features and capabilities.

Dimensional Requirements and Space Configuration

Interior Workspace Dimensions

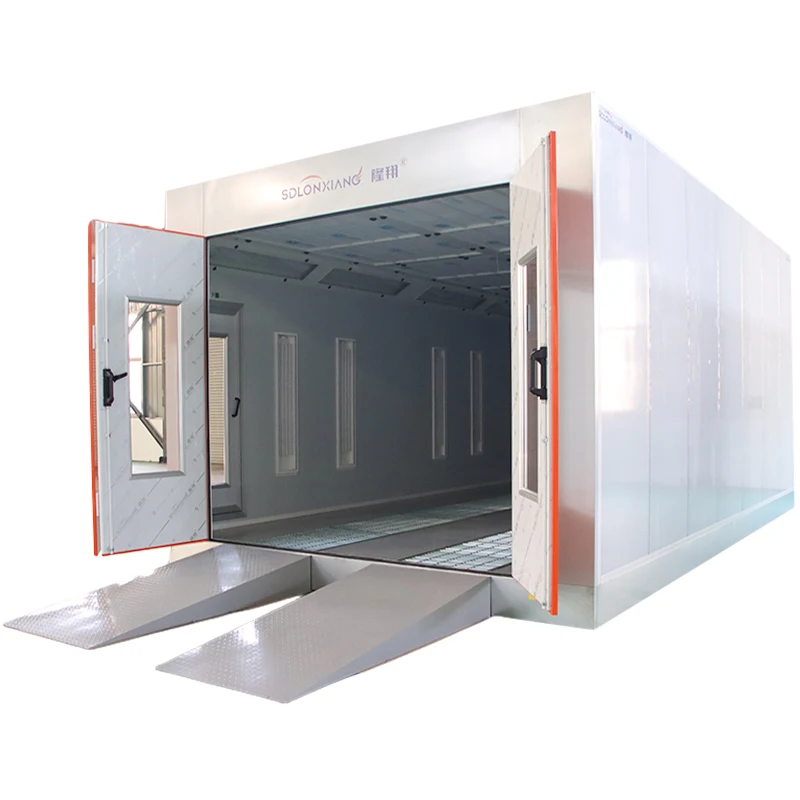

The internal dimensions of paint booths for sale directly determine the size and quantity of items that can be processed efficiently. Standard automotive paint booths typically measure between 14 to 26 feet in length, 8 to 14 feet in width, and 8 to 10 feet in height. However, custom applications may require significantly larger or smaller configurations. Industrial paint booths for sale often feature expandable designs that accommodate varying workpiece dimensions while maintaining optimal airflow patterns.

Workspace height considerations extend beyond the actual workpiece dimensions to include operator movement, equipment access, and maintenance requirements. Insufficient height can restrict spray gun angles and create safety hazards for operators. Additionally, the door opening dimensions must provide adequate clearance for loading and unloading operations. Many paint booths for sale offer multiple door configurations, including single-leaf, double-leaf, and overhead designs to optimize workflow efficiency.

External Footprint and Installation Space

The total footprint encompasses not only the booth structure but also associated equipment such as air handling units, control panels, and utility connections. Paint booths for sale require additional clearance space for maintenance access, typically 3 to 6 feet on all sides. The ceiling height requirements extend beyond the booth itself to accommodate ductwork, lighting fixtures, and ventilation components. Facility planning must account for these spatial demands during the initial evaluation process.

Foundation requirements vary significantly among different paint booth designs. Some models require concrete pads with specific load-bearing capabilities, while others utilize steel frame foundations. The installation complexity affects both initial costs and long-term maintenance accessibility. Modular paint booths for sale often provide advantages in terms of installation flexibility and future reconfiguration possibilities.

Airflow Systems and Ventilation Specifications

Air Movement Patterns and Velocity

Proper airflow management represents the most critical aspect of paint booth performance. Paint booths for sale typically feature three primary airflow patterns: downdraft, crossdraft, and semi-downdraft configurations. Downdraft systems provide superior finish quality by drawing overspray downward through floor grates, minimizing contamination on painted surfaces. Crossdraft designs offer cost-effective solutions for budget-conscious operations, while semi-downdraft systems combine elements of both approaches.

Air velocity specifications must balance overspray capture efficiency with operator comfort and energy consumption. Industry standards recommend face velocities between 100 to 150 feet per minute for most applications. Higher velocities improve contamination control but increase operating costs and may cause finish defects in sensitive applications. Paint booths for sale should provide adjustable airflow controls to optimize performance for different coating materials and application techniques.

Filtration Systems and Efficiency Ratings

Multi-stage filtration systems protect both the work environment and painted surfaces from contamination. Intake air filtration typically employs progressively finer media, starting with coarse pre-filters and advancing to high-efficiency particulate air filters. The filtration efficiency directly impacts finish quality and maintenance intervals. Many paint booths for sale incorporate disposable filter media for convenient maintenance, while others utilize washable elements for reduced operating costs.

Exhaust air filtration addresses environmental compliance requirements and operational safety concerns. Dry filtration systems capture overspray particles through progressive stages of filter media. Wet scrubber systems provide higher capture efficiency for certain applications but require more complex maintenance procedures. The choice between filtration technologies affects both initial equipment costs and long-term operational expenses.

Heating and Climate Control Systems

Temperature Control Capabilities

Precise temperature control ensures optimal coating application conditions and curing performance. Paint booths for sale typically offer temperature ranges from ambient conditions up to 180 degrees Fahrenheit for standard applications. Specialized systems may provide higher temperatures for specific coating materials or accelerated curing processes. The heating system capacity must match the booth volume and expected heat losses through walls, ceiling, and air exchange.

Uniform temperature distribution prevents coating defects caused by thermal variations across the workpiece surface. Advanced paint booths for sale incorporate multiple temperature sensors and zone-based control systems to maintain consistent conditions throughout the workspace. The response time and accuracy of temperature control systems directly affect both finish quality and process efficiency.

Humidity Management Features

Humidity control prevents common coating defects such as blushing, poor adhesion, and surface contamination. Optimal relative humidity levels typically range between 40 to 60 percent for most coating applications. Paint booths for sale may include dehumidification systems for high-humidity environments or humidification capabilities for excessively dry conditions. The climate control system must respond quickly to changing conditions while maintaining stable operating parameters.

Advanced humidity management systems monitor both absolute and relative humidity levels throughout the spray and curing cycles. Some paint booths for sale feature automatic adjustment capabilities that modify ventilation rates and heating output to maintain optimal conditions. These sophisticated control systems reduce operator intervention requirements while ensuring consistent coating quality.

Lighting Systems and Visual Quality

Illumination Levels and Distribution

Adequate lighting enables operators to achieve consistent coating application while identifying potential defects during the spraying process. Industry standards recommend minimum illumination levels of 100 foot-candles for general coating work, with higher levels required for precision applications. Paint booths for sale should provide uniform light distribution without creating shadows or glare that interfere with operator visibility.

LED lighting systems have become increasingly popular in modern paint booths for sale due to their energy efficiency, longevity, and consistent color temperature. Traditional fluorescent lighting remains common in budget-oriented systems but may require more frequent maintenance and replacement. The lighting arrangement should minimize fixture contamination while providing easy access for cleaning and maintenance procedures.

Color Rendering and Accuracy

Accurate color perception requires lighting systems with high color rendering index ratings, typically 85 or higher for critical applications. Poor color rendering can lead to mismatched repairs, incorrect color application, and quality control problems. Many paint booths for sale incorporate specialized automotive lighting that simulates daylight conditions for optimal color matching accuracy.

Multiple lighting zones enable operators to evaluate finish quality under different conditions throughout the painting process. Some advanced paint booths for sale feature adjustable lighting intensity and color temperature settings to accommodate various inspection requirements. These capabilities prove particularly valuable in custom color matching and high-quality finishing operations.

Construction Materials and Durability

Panel Materials and Insulation

The construction materials directly affect booth longevity, energy efficiency, and maintenance requirements. Paint booths for sale typically utilize steel panel construction with various insulation options. Double-wall panels with polyurethane foam insulation provide excellent thermal performance and structural integrity. Single-wall designs offer cost advantages but may require additional insulation for energy efficiency.

Interior surface finishes must withstand repeated cleaning and chemical exposure while maintaining smooth, non-contaminating surfaces. Many paint booths for sale feature powder-coated or specialized paint finishes that resist chemical attack and facilitate cleaning procedures. The panel joint design affects both air leakage and contamination potential, making proper sealing critical for optimal performance.

Floor Systems and Drainage

Floor construction must support both the workpiece weight and operator traffic while providing safe, non-slip surfaces. Paint booths for sale offer various floor options, including steel grating, concrete, and specialized coating systems. Grated floors facilitate downdraft airflow but require regular cleaning to maintain performance. Solid floors provide easier maintenance but may require different airflow configurations.

Drainage systems remove wash water, condensation, and accidental spills to maintain safe operating conditions. Proper slope and drain sizing prevent water accumulation and facilitate cleaning procedures. Some paint booths for sale incorporate specialized drainage systems that separate overspray waste from water runoff for environmental compliance and waste management efficiency.

Control Systems and Automation Features

User Interface and Programming

Modern paint booths for sale incorporate sophisticated control systems that manage multiple operational parameters simultaneously. User-friendly interfaces enable operators to select pre-programmed cycles, monitor system status, and adjust settings as needed. Touchscreen displays provide intuitive navigation and real-time feedback on system performance. The control complexity should match operator skill levels while providing necessary functionality for optimal results.

Programmable logic controllers enable precise timing and sequencing of spray, flash-off, and cure cycles. Advanced paint booths for sale may include recipe management capabilities that store specific parameter sets for different coating materials and applications. These features reduce setup time, improve consistency, and minimize operator training requirements for complex finishing operations.

Safety Interlocks and Monitoring

Comprehensive safety systems protect both operators and equipment from hazardous conditions. Paint booths for sale must incorporate emergency stop functions, airflow monitoring, and temperature limit controls to prevent dangerous situations. Flame detection systems provide early warning of fire hazards, while gas detection capabilities monitor for harmful vapor concentrations.

Remote monitoring capabilities enable facility managers to track booth performance and maintenance requirements from central locations. Some paint booths for sale feature internet connectivity for remote diagnostics and technical support. These advanced monitoring systems can predict maintenance needs, optimize energy consumption, and document operational parameters for quality assurance purposes.

FAQ

What size paint booth is needed for automotive applications

Standard automotive paint booths typically require interior dimensions of 14 feet wide, 24 feet long, and 9 feet high to accommodate passenger vehicles comfortably. Larger vehicles such as trucks or SUVs may require booths up to 16 feet wide and 28 feet long. The booth size should allow at least 3 feet of clearance around the vehicle for proper operator movement and airflow patterns. Commercial truck applications often need paint booths for sale with dimensions exceeding 40 feet in length and 14 feet in height.

How much power consumption should be expected from a paint booth

Power consumption varies significantly based on booth size, heating capacity, and airflow requirements. A typical automotive paint booth consumes between 50 to 150 kilowatts during operation, with larger industrial units requiring 200 kilowatts or more. Heating systems account for the majority of energy usage, particularly during winter months. Many paint booths for sale now feature energy-efficient designs with variable speed drives and heat recovery systems that can reduce operating costs by 30 to 50 percent compared to traditional models.

What maintenance intervals are required for optimal performance

Regular maintenance schedules ensure consistent performance and extend equipment life. Intake filters typically require replacement every 2 to 4 weeks depending on environmental conditions and usage patterns. Exhaust filters may last 3 to 6 months in normal applications. Monthly cleaning of lights, walls, and floors prevents contamination buildup. Annual professional inspections should verify burner operation, control calibration, and safety system functionality. Well-maintained paint booths for sale can provide 15 to 20 years of reliable service with proper care.

Are there specific environmental compliance requirements to consider

Environmental regulations vary by location but typically address air emissions, waste disposal, and workplace safety standards. Most jurisdictions require proper filtration systems to capture overspray particles and volatile organic compounds. Waste paint and solvents must be disposed of through licensed waste management companies. Operator exposure limits mandate adequate ventilation and personal protective equipment. Many paint booths for sale include compliance documentation and certified test data to facilitate permit applications and regulatory approvals.