Selecting the right paint booth represents a critical investment for any automotive, industrial, or manufacturing facility seeking professional finishing capabilities. When evaluating paint booths for sale, size and layout considerations fundamentally determine operational efficiency, product quality, and long-term return on investment. These factors influence everything from workflow optimization to regulatory compliance, making careful evaluation essential before making a purchase decision.

The size and configuration of your paint booth directly impacts production capacity, energy efficiency, and the types of projects your facility can handle. Understanding these parameters helps businesses make informed decisions that align with current needs while accommodating future growth. Modern manufacturing environments require flexible solutions that maximize available space while maintaining optimal working conditions for technicians and ensuring consistent finishing results across all applications.

Understanding Paint Booth Dimensions and Workspace Requirements

Calculating Optimal Booth Size for Your Operations

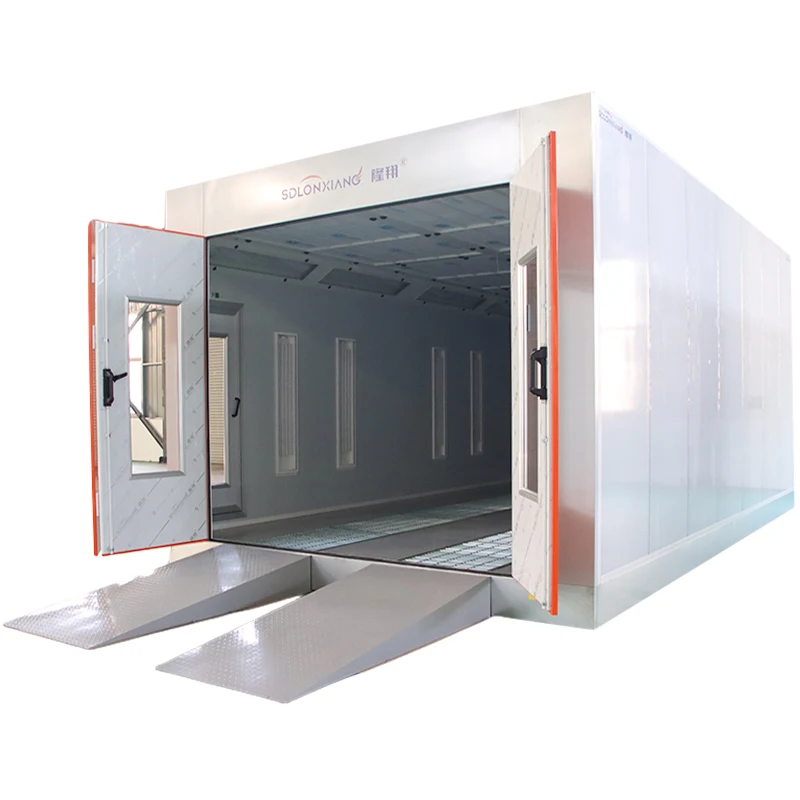

Determining the appropriate size for paint booths for sale requires careful analysis of your largest workpieces and anticipated production volumes. Standard automotive paint booths typically measure 14 feet wide, 9 feet high, and 26 feet long, but industrial applications often demand custom dimensions. Consider the clearance space needed around objects being painted, allowing technicians to move freely while maintaining proper spray distances and angles.

Height considerations become particularly important when dealing with tall vehicles, machinery, or architectural components. A booth that seems adequate in width and length may prove inadequate if vertical clearance restricts access to upper surfaces. Factor in overhead lighting, ventilation equipment, and any lifting mechanisms that might reduce effective working height within the booth interior.

Width requirements extend beyond the actual workpiece dimensions to accommodate spray patterns, overspray collection, and operator movement. Professional paint application requires maintaining consistent distances from surfaces, typically 6-8 inches for conventional spray guns and 4-6 inches for HVLP systems. Insufficient width can force technicians into awkward positions that compromise finish quality and increase material waste.

Evaluating Ceiling Height and Vertical Space

Vertical space planning involves more than simply measuring your tallest workpiece. Modern paint booths for sale incorporate sophisticated ventilation systems that require specific ceiling heights to function effectively. Downdraft systems, considered the gold standard for automotive finishing, need adequate plenum space above the work area to ensure proper airflow distribution and contaminant removal.

Consider future equipment additions when evaluating ceiling height requirements. Automated spray systems, rotating fixtures, or overhead conveyor systems may require additional vertical clearance. Planning for these possibilities during initial booth selection prevents costly modifications later as operations expand or technology upgrades become necessary.

Local building codes and fire safety regulations often mandate minimum ceiling heights for paint booth installations. These requirements vary by jurisdiction and booth size, making consultation with local authorities essential during the planning phase. Compliance issues discovered after purchase can result in expensive modifications or complete booth relocation.

Layout Configuration Options and Workflow Optimization

Single versus Multiple Booth Configurations

Production facilities must decide between single large booths or multiple smaller units when evaluating paint booths for sale. Single booth configurations maximize workspace flexibility and can accommodate oversized items, but create production bottlenecks when multiple projects require simultaneous processing. This approach works well for custom fabrication shops handling diverse, large-scale projects with varying completion schedules.

Multiple booth installations enable parallel processing of different projects while allowing specialized configurations for specific applications. Automotive shops might combine a larger booth for complete vehicle painting with smaller units for parts and touch-up work. This segregation improves efficiency by matching booth capabilities to project requirements while maintaining continuous production flow.

Consider maintenance schedules when planning booth configurations. Single booth operations must halt production during filter changes, equipment servicing, or cleaning procedures. Multiple booth setups provide operational redundancy, allowing continued production while individual units undergo maintenance. This flexibility becomes crucial for businesses with tight delivery schedules or seasonal demand fluctuations.

Integration with Existing Facility Layout

Successful paint booth integration requires comprehensive facility analysis to optimize material flow and minimize handling steps. Evaluate the path from preparation areas through the booth to curing and final inspection zones. Minimizing transport distances reduces labor costs and potential damage to freshly painted surfaces while improving overall production efficiency.

Utility infrastructure significantly impacts booth placement options within existing facilities. Paint booths for sale require substantial electrical service, compressed air supply, and exhaust systems that may necessitate facility modifications. Early identification of these requirements helps budget for installation costs and prevents delays during implementation phases.

Traffic patterns around the booth affect both safety and productivity. Ensure adequate clearance for equipment movement, emergency access, and material delivery while preventing interference with other facility operations. Poor layout decisions can create safety hazards and reduce overall facility efficiency even when the booth itself operates optimally.

Environmental and Safety Considerations in Size Planning

Ventilation and Air Quality Management

Proper ventilation design depends heavily on booth size and configuration when selecting paint booths for sale. Larger booths require proportionally greater airflow volumes to maintain consistent air velocity across work surfaces. This relationship affects energy costs, filter life, and environmental compliance, making size selection a critical factor in long-term operational expenses.

Air change rates must meet regulatory standards while providing optimal working conditions for technicians. Oversized booths may struggle to maintain required air velocities without excessive energy consumption, while undersized units cannot achieve proper contaminant removal. Balancing these factors requires careful calculation of cubic footage and airflow requirements during the selection process.

Consider seasonal variations in ambient conditions when planning ventilation capacity. Winter heating and summer cooling loads vary significantly with booth size, affecting operational costs throughout the year. Energy-efficient booth designs incorporate heat recovery systems and variable-speed fans that adjust to actual requirements rather than maintaining maximum capacity continuously.

Fire Safety and Emergency Access Requirements

Fire safety codes mandate specific spacing requirements around paint booths based on size and fire suppression system type. Larger installations may require additional emergency exits, specialized suppression systems, or increased clearances from adjacent structures. These requirements can significantly impact facility layout and available space for other operations.

Emergency response procedures must accommodate booth size and layout characteristics. Larger booths may require multiple access points for emergency personnel, while complex configurations need clear evacuation routes that remain accessible during normal operations. Planning these safety features during booth selection prevents costly retrofits and ensures regulatory compliance.

Hazardous material storage and handling procedures vary with booth size and production volumes. Larger operations typically generate more waste and require more extensive containment systems. Consider these secondary requirements when evaluating total space needs and facility modifications required for new paint booth installations.

Cost Implications of Size and Layout Decisions

Initial Investment and Installation Costs

Size directly correlates with initial costs when purchasing paint booths for sale, but the relationship extends beyond simple linear scaling. Larger booths require more robust structural support, increased utility capacity, and more sophisticated control systems that can disproportionately increase total investment requirements. Understanding these cost relationships helps establish realistic budgets for booth acquisition and installation.

Installation complexity increases with booth size due to component handling, assembly space requirements, and utility connections. Large booth sections may require specialized lifting equipment or facility modifications to enable delivery and positioning. Factor these logistics costs into total project budgets to avoid unexpected expenses during implementation phases.

Custom sizing options typically carry premium pricing compared to standard configurations, but may provide better long-term value through improved efficiency and reduced operational constraints. Evaluate whether standard sizes meet operational requirements or if custom dimensions justify additional investment through enhanced productivity and flexibility.

Long-term Operational Expenses

Energy consumption varies significantly with booth size and utilization patterns when operating paint booths for sale. Larger booths consume more energy for heating, cooling, and ventilation even when processing small items, while undersized booths may require multiple cycles for large projects. Optimizing size selection balances initial costs against long-term operational efficiency.

Filter replacement costs increase with booth size due to larger filter areas and higher airflow volumes. However, larger filters often provide longer service life and better contaminant capture efficiency, potentially reducing overall filtration costs per unit of production. Consider total cost of ownership rather than initial filter pricing when evaluating size options.

Maintenance requirements generally scale with booth complexity rather than simple size measurements. Larger booths may incorporate more sophisticated systems that require specialized service capabilities, while smaller units might use simpler components with lower maintenance costs. Evaluate available service support and maintenance capabilities when selecting booth specifications.

Future Growth and Expansion Planning

Scalability and Modification Options

Business growth often requires expanded painting capabilities that may exceed initial booth specifications. When evaluating paint booths for sale, consider expansion possibilities through modular designs or adjacent booth additions. Some manufacturers offer systems designed for future enlargement without complete replacement of existing equipment and infrastructure.

Modular booth systems provide flexibility for incremental capacity increases as business demands grow. These designs typically cost more initially but can provide significant savings when expansion becomes necessary. Evaluate whether modular options align with anticipated growth patterns and facility constraints before making final purchasing decisions.

Technology evolution may require booth modifications or replacements within the equipment's useful life. Consider whether selected booth designs can accommodate new spray technologies, automation systems, or environmental regulations without major reconstruction. Future-proofing decisions during initial purchase can prevent premature obsolescence and extend equipment life cycles.

Market Demand and Production Volume Changes

Market conditions can dramatically alter production requirements over a booth's service life, making flexibility essential when selecting paint booths for sale. Economic downturns may reduce demand while market expansion could require increased capacity. Booth selection should consider these possibilities and provide reasonable adaptability to changing conditions.

Seasonal demand variations affect booth utilization and may justify different sizing strategies than constant production requirements. Operations with significant seasonal peaks might benefit from booth designs that accommodate maximum capacity efficiently while remaining cost-effective during slower periods.

Product mix changes can alter optimal booth configurations as businesses evolve or market opportunities develop. Consider whether selected booth dimensions can handle anticipated product variations or if flexible configurations might provide better long-term value despite higher initial costs.

FAQ

What is the standard size for automotive paint booths for sale

Standard automotive paint booths typically measure 14 feet wide, 9 feet high, and 26 feet long, providing adequate space for most passenger vehicles and light trucks. However, shops working on larger vehicles like RVs, buses, or commercial trucks often require custom dimensions. The key is ensuring 3-4 feet of clearance around the vehicle for proper spray gun operation and technician movement.

How do I determine if my facility can accommodate a specific paint booth size

Facility assessment requires measuring available floor space, ceiling height, and utility access points while accounting for required clearances around the booth. Consider building structure, electrical capacity, compressed air supply, and exhaust system requirements. Professional site surveys help identify potential obstacles and ensure proper integration with existing facility systems before purchasing paint booths for sale.

Can paint booths be modified after installation if my needs change

Modification possibilities depend on booth design and construction type. Some modular systems allow expansion or reconfiguration, while others require complete replacement for significant size changes. Minor modifications like adding equipment mounts or changing door configurations are often possible, but structural changes may be limited by original design constraints and local building codes.

What are the main cost factors when comparing different sized paint booths for sale

Cost factors include initial purchase price, installation complexity, utility requirements, and ongoing operational expenses. Larger booths require more energy for heating and ventilation, larger filter systems, and potentially more sophisticated control systems. However, they may provide better efficiency for high-volume operations. Consider total cost of ownership over the equipment's expected service life rather than focusing solely on initial purchase price.