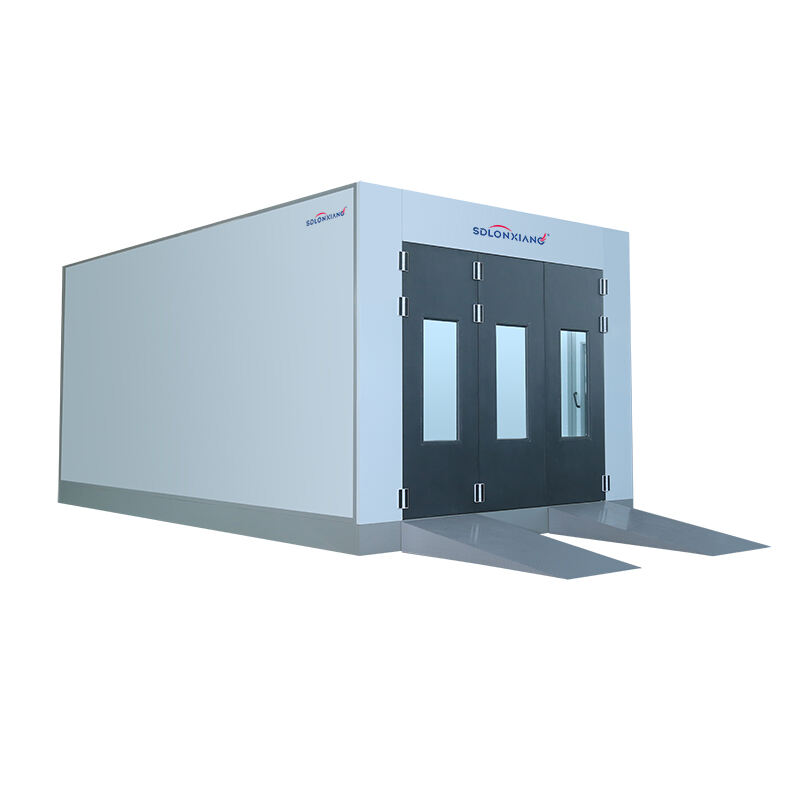

manual spray booth

A manual spray booth represents a fundamental solution for professional painting operations across diverse industries, providing controlled environments that ensure superior finishing results. This essential equipment creates an enclosed workspace where operators can apply coatings, paints, and finishes with precision while maintaining optimal safety standards. The manual spray booth functions as a containment system that captures overspray particles and harmful vapors, preventing contamination of surrounding areas and protecting workers from hazardous exposure. The core design incorporates powerful ventilation systems that maintain consistent airflow patterns, effectively removing paint particles and chemical fumes from the workspace. Advanced filtration mechanisms within these booths trap contaminants before air discharge, ensuring compliance with environmental regulations. Temperature control systems maintain ideal conditions for paint application, preventing issues like orange peel texture or improper curing. Lighting arrangements provide uniform illumination across all work surfaces, enabling operators to detect imperfections and achieve consistent color matching. The booth structure typically features modular panels that can be configured to accommodate various project sizes and specifications. Safety features include emergency shut-off systems, fire suppression capabilities, and explosion-proof electrical components designed for hazardous environments. These booths serve manufacturing facilities producing automotive components, aerospace parts, industrial machinery, and consumer goods requiring high-quality finishes. Furniture manufacturers utilize manual spray booths for applying stains, lacquers, and protective coatings to wooden products. Metal fabrication shops depend on these systems for applying primers, basecoats, and topcoats to steel and aluminum components. The versatility of manual spray booth operations extends to refinishing services, custom painting projects, and specialty coating applications that demand precise environmental control.